INEX SUCTION BLAST CABINET with 300 CFM RECLAIMER

Page 6

© 2005 CLEMCO INDUSTRIES CORP.

•

www.clemcoindustries.com

•

Manual No. 21803 Rev. D 03/05

3.5 Blasting

Technique

3.5.1

Blasting technique is similar to spray painting

technique. Smooth continuous strokes are most

effective. The distance from the part affects size of blast

pattern. Under normal conditions, hold the nozzle

approximately 3" to 6" from the surface of the part.

4.0 ADJUSTMENTS

4.1 Blasting

Pressure

4.1.1

The pilot regulator, located in the light shield,

enables the user to adjust blasting pressure to suit the

application. The suitable pressure for most purposes is

80 psi. Lower pressures may be used for delicate work.

In all cases, highest production can be achieved only

when pressure is carefully monitored.

4.1.2

To adjust, unlock the knob, and turn it clockwise

to increase pressure or counter-clockwise to decrease

pressure. Pressure will usually drop from closed-line

pressure when blasting is started. Once operating

pressure is set, lock the knob to maintain the setting.

4.2 Air

Jet

Adjustment

4.2.1

The air jet should be screwed 4-1/2 to 5 full

turns into the gun body. Doing so will leave 3-1/2 to 4

threads exposed past the lock nut. Tighten the lock nut

to hold the jet in place. See Section 8.1 or 8.3 for

optional adjusting tool.

4.3

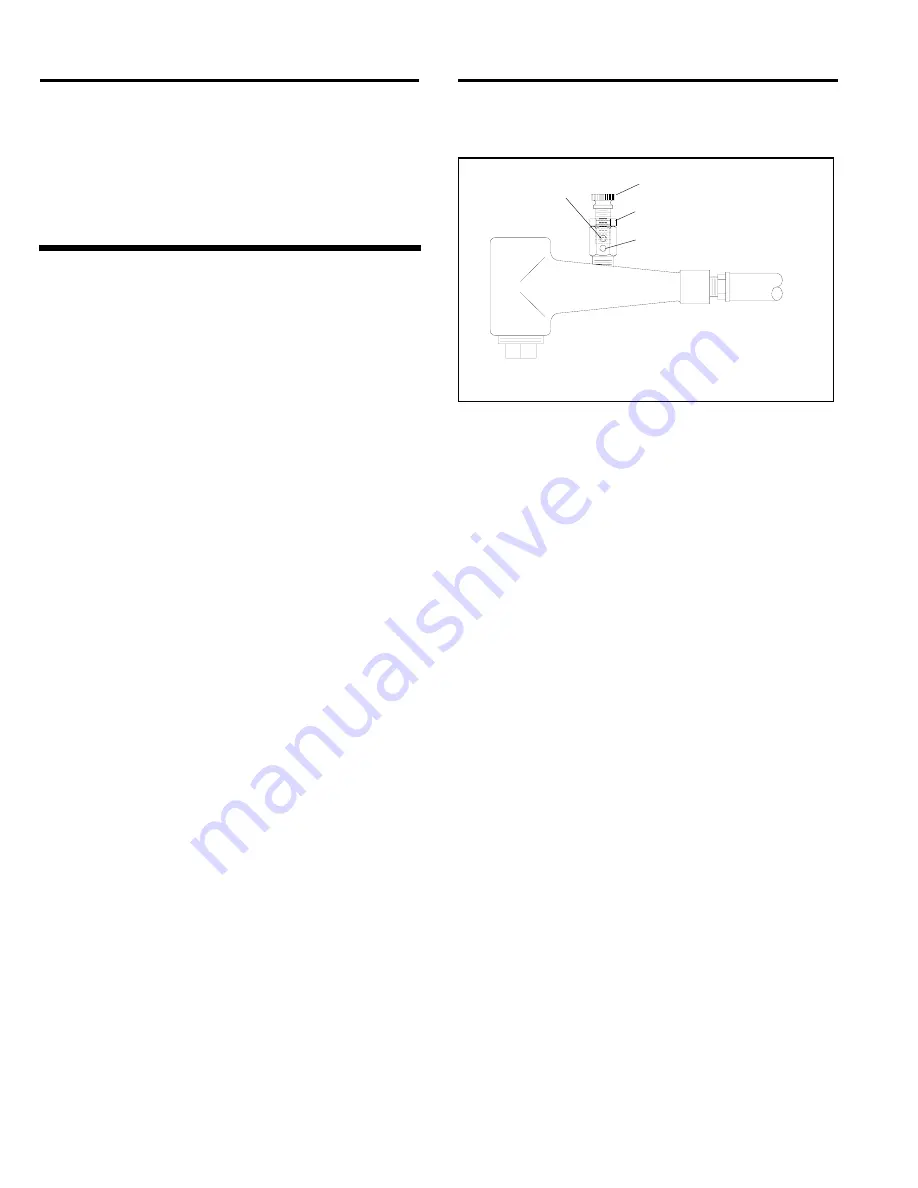

Media/Air Mixture, Figure 4

4.3.1

Check the media stream for correct media/air

mixture; media flow is smooth and appears as a light mist

coming from the nozzle.

4.3.2

If media does not flow smoothly, loosen the

locking nut, and adjust the metering screw until the upper

holes in the metering stem are closed-off, and the lower

holes are fully open. See Figure 4. This adjustment is a

starting point.

4.3.3

If pulsation occurs in the media hose, either media

is damp and caked, or not enough air is entering the

media stream. While blasting, loosen the locking nut and

slowly turn the adjusting screw out (counterclockwise

when viewed from the top) until the media flows smoothly.

Tighten the locking nut finger-tight to maintain the setting.

4.3.4

If media flow is too light, decrease air in the

mixture by turning the metering screw in (clockwise when

viewed from the top) covering more of the holes so less air

enters the media hose. Tighten the locking nut finger-tight

to maintain the setting.

Figure

4

4.4

Static Pressure (dry filter models only)

4.4.1

Correct static pressure requirements vary with

size, weight and type of media.

4.4.2

Adjust static pressure by opening (handle

horizontal) or closing (handle vertical) the damper. The

damper is located on the inlet on dry. If the damper is

not opened enough, the reclaimer will not remove fines,

resulting in dusty media, poor visibility, and possible

media blockage in the conveying hose. If the damper is

opened too far, it may cause carryover (usable media

carried into the dust collector) and result in excessive

media consumption. Open only as far as necessary to

obtain a balance of dust removal without media

carryover.

4.4.3

A manometer is useful when adjusting or

monitoring static pressure. The optional manometer kit is

listed under Optional Accessories in Section 8.1. The

following are static pressure starting points for given

media. Static pressure may need to be lower with finer

media, higher with coarser media.

Glass Bead No. 8 to 13 ..................................... 2-1/2 - 3"

Alox. 60 & coarser ................................................... 4 - 5"

Alox. 80 & finer .................................................. 2-1/2 - 3"

4.4.4

If the damper has been adjusted and carryover

or excessive dust in the media continues to be a

problem, the optional adjustable vortex cylinder, which is

standard on pull through reclaimers, may help retain

media. The vortex cylinder is usually required only when

using 200 mesh and finer media, or lightweight media.

See Section 4.5, and Accessories in Section 8.1.

Adjusting Screw

Locking Nut

Lower holes fully open

Upper holes

fully Closed