PV154 - 923-03499

11

P50W26 - SERVICING

SERVICING

X: 0.290±0.003, Y: 0.300±0.003

Color temperature: 8, 500¡K±500¡K

7) Exit adjustment mode using o Key.

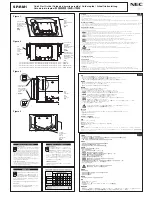

DDC DATA INPUT

REQUIRED TEST EQUIPMENT

1) A jig for adjusting PC, DDC. (PC serial to D-

sub. Connection equipment)

2) S/W for writing DDC(EDID data write & read)

3) D-Sub 15P cable, D-Sub to DVI Connector (Con-

nect to DVI Jack)

PREPARATION FOR ADJUSTMENT

1) Set devices as above and turn the PC, jig on.

2) Put S/W for writing DDC (EDID data write &

read) into operation. (operated in DOS mode.)

SEQUENCE OF ADJUSTMENT

DDC DATA INPUT FOR ANALOG-RGB

1) Put the set on the table and turn the power on.

2) Connect PC Serial to D-sub 15P Cable of JIG for

DDC adjustment to RGB1 terminal (D-Sub 15Pin).

3) Operate S/W for DDC record and select DDC Data for

analog RGB in Model Menu.

4) Operate EDID Write command.

5) Operate EDID Read command and check whether

Check Sum is OK.

6) If Check Sum is NG, repeat 3-4.

7) If Check Sum is OK, DDC Data for Analog-RGB input

is completed.

DDC DATA INPUT FOR DIGITAL-RGB

1) Connect PC Serial to DVI Cable of JIG for DDC

adjustment to RGB2 terminal (DVI Jack).

2) Operate S/W for DDC record and select DDC Data for

Digital RGB in Model Menu.

3) Operate EDID Write command.

4) Operate EDID Read command and check whether

Check Sum is OK.

5) If Check Sum is NG, repeat 3 & 4.

6) If Check Sum is OK, DDC Data for Digital-RGB input

is completed.

COMPONENT OFF-SET ADJUSTMENT

1) Input the signal to HD-STB(SK-010T) and receive 14Ch.

2) Input Video signal and Component 720P, 1080i sig-

nal of HD-STB into AV1 and Component input part.

3) Select Twin Picture by pressing ADJ twice on R/C, check

component in the main picture and AV1 in the sub

picture.

4) Adjust the R-OFFSET, B-OFFSET color impression of

component(Main picture) and external Input(Sub

picture) same by pressing ,- key.

Summary of Contents for P50W26

Page 4: ......

Page 8: ......

Page 21: ......

Page 22: ......

Page 25: ...29 P50W26 DIAGRAMS PV154 923 03499 P50W26 Block Diagram...

Page 26: ...30 P50W26 DIAGRAMS PV154 923 03499 P50W26 Main PCB M A I N TOP...

Page 28: ...32 P50W26 DIAGRAMS PV154 923 03499 P50W26 Other PCBs...