SERVICING

3828VD0171G

3-4

DIGITAL FCS - SERVICING

HORIZONTAL-TILT WEDGE ADJUST-

MENT

The vertical lines at 3 o’clock and 9

o’clock are converged by horizontally

tilting the yoke and inserting a

wedge.

Adjust first at 4 or 8 o’clock, which-

ever has the larger space, until the

wedge is firmly seated between the CRT

glass and yoke coils. Then, insert the

3rd wedge in the remaining horizontal

tilt position until it is firmly seated

between the CRT glass and yoke coils.

Convergence at the 3 and 9 o’clock should

be maintained during this operation.

When the 3 wedges are firmly installed

and positioned for acceptable conver-

gence, lock the wedges in place by ap-

plying a 2.5 inches long strip of tape

across the tabs of each wedge firmly

against the CRTM glass. The CRT glass

surface should be clean and free of

dust and other foreign material.

UNUSUAL TILT CASE

There may be some instances where the

picture tube and yoke will require ver-

tical tilt in the opposite (up) direc-

tion to obtain convergence. In such

cases, insert the vertical tilt wedge

at the bottom (6 o’clock) position.

Follow through on the horizontal tilt

adjustment by using the 2 and 10 o’clock

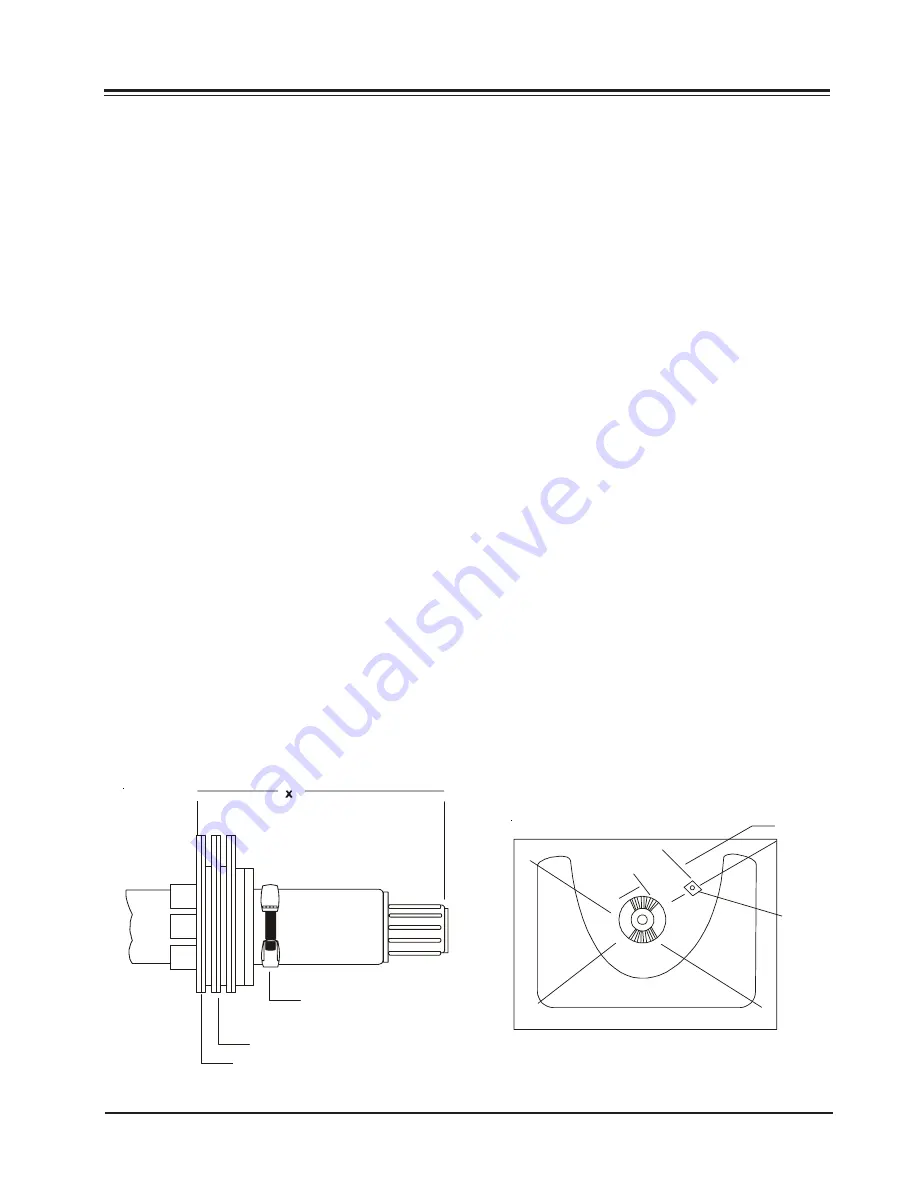

4 Pole Magnets

Clamp and Screw

6 Pole Magnets

2 Pole Magnets

2" To 3"

MAGNET

positions and secure each wedge with a

piece of tape, as described above.

IMPROVING CRT CORNER PURITY

CRTs that display corner purity prob-

lems even after following the service

procedures can be modified with a pic-

ture correction kit (P/N 949-00050).

The purity can be improved by placing a

picture-correction magnet (included in

the kit) on the CRT funnel. Refer to

the following modification steps and

illustration to place the magnet prop-

erly. Fully degauss the CRT before in-

stalling correction magnets.

MODIFICATION 1. Place the magnet on

the CRT funnel as shown in the figure

displayed below, in the quadrant ex-

hibiting impurity.

2. Rotate the magnet in place to the

position shown for best purity.

3. Place a piece of 1/2" by 2" long

Fiberglass tape over the magnet to hold

it in place.

4. Degauss the CRT once magnet is in

place to insure that the magnet is not

over the internal magnet shield.

Note: If the magnet is placed over the internal

magnet shield, any apparent purity

correction will disappear after degaussing.

Reposition the correction magnet off the

internal shield and degauss again.