27

Air system

balancing

All ductwork must be complete

and fully connected. All return

and supply grilles, lint screens

and panels must be properly

installed before air balancing to

ensure that the system is being

balanced at the true system

operating conditions.

Each individual unit and its

attached ductwork is a unique

system with its own operating

characteristics. Because of this,

air balancing is generally done by

a trained balance specialist who

are familiar with the procedures

required to properly establish the

fan system and air distribution

operating conditions. This should

not be attempted by unqualified

personnel.

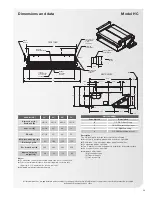

To accurately commission the

primary air flow to the unit,

measure the static presure in the

primary air plenum through the

commissioning sample tube. To

achieve this, remove the sealing

plug from the commissioning

sampling tube and connect the

pressure-sensing instrument

(digital manometer) to the

commissioning sampling tube.

n

Do not attempt to measure

the static pressure in the

flexible duct connection.

Measure only at the provided

commissioning sampling tube

for commissioning purposes.

To obtain the designed primary

air and total air flow rate, adjust

the primary air volume balancing

damper integral to the unit as

necessary to obtain the primary

air plenum pressure to achieve

the specified/design primary air

flow using the plenum pressure

versus primary air flow curve

supplied for each unit. To adjust

the damper push or pull the

handle located at position 4.

Replace the plug to seal the

primary air commissioning

sampling tube on completion.

After proper system operation

is established, the actual unit

air delivery for each unit should

be measured and recorded for

future reference.

the piping mains to prevent this

material from entering the units

during normal operation.

During system filling, air venting

from the unit is accomplished

by the use of the standard,

manual air vent that is installed

at the top of each coil’s header,

if supplied by the manufacturer

or alternately through another

means supplied by the installing

contractor. To vent the air from

the coil, turn the slotted coin

vent until all of the air has been

vented from the coil. When water

begins to escape from the vent,

close the coin vent.

The air vents provided are not

intended to replace the main

system air vents and may not

release air trapped in other

parts of the system. Inspect

the entire system for potential

air traps and independently

vent those areas as required.

In addition, some systems may

require repeated venting over

time to fully eliminate air in the

system.

Cooling/heating

system

Prior to the water system start-

up and balancing, the chilled/

hot water system should be

thoroughly flushed to clean

out dirt and debris which may

have accumulated in the piping

during construction. During this

procedure, all unit service valves

must be in the closed position.

This will prevent any foreign

material from entering the unit’s

heat exchanger and clogging

valves and metering devices.

Strainers should be installed in

Summary of Contents for HC

Page 1: ...i Cooling Fresh Air Clean Air Heating Induction Unit Installation Operation and Maintenance...

Page 34: ......

Page 35: ......