Receiving

General information

This installation and start-up

instructions literature is for

horizontal and vertical Induction

Units. Induction Units are

hydronic terminal units designed

for year-round cooling or

cooling/heating. Your equipment

is initially protected under the

Zehnder Rittling standard 2-year

warranty provided the steps

outlined in this manual for initial

inspection, installation, periodic

maintenance and normal every

day operation of the equipment

are followed. This manual should

be thoroughly reviewed prior to the

installation, start-up or maintenance

of the equipment. If any questions

arise, please contact your local

Zehnder Rittling sales representative

or the factory before proceeding any

further.

There are a multitude of options

and accessories available with the

equipment covered in this manual.

For more specific details on the

included options and accessories,

refer to the order acknowledgment,

approved submittals and catalogs.

writing before any corrective

action is taken. The factory

must be fully informed of the

expected costs before the work

is begun. Zehnder Rittling is

not responsible for any repairs

or alterations made by the

purchaser without Zehnder

Rittling’s written consent and

will not accept any back charges

associated with these repairs

or alterations. The return of

damaged equipment will not

be accepted without written

authorization from Zehnder

Rittling.

A unit that has received a written

Return Goods Authorization will

be inspected by Zehnder Rittling

upon receipt. Any damage,

missing parts, reworking or

repackaging resulting from prior

installation will constitute just

cause for Zehnder Rittling to

issue partial credit.

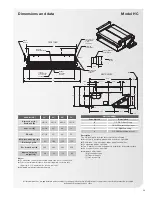

Several components are shipped

loose for field installation and

to offer added protection during

shipment and job site storage.

These items may include; lint

screens, wall mounting strips, air

transition fittings, etc.

Upon delivery, examine the

shipment against the bill of

lading to make sure all of the

units have been received and

then check each unit carefully

for shipping damage. Any

damage should be reported to

the freight carrier and a claim

should be filed with them. Ensure

the shipping company makes

proper notation of any shortages

or damage on all copies of the

freight bill. Concealed damage

not discovered during unloading

must be reported to the shipping

company within 15 days of

receipt of the shipment.

All units are shipped F.O.B.

factory. Therefore, Zehnder

Rittling is not responsible for

damage during transit. It is the

responsibility of the installing

contractor to inspect and verify

that the units shipped were in

fact the correct model number,

have the correct nozzles, etc.

Any discrepancies should be

reported to the local sales

representative for immediate

resolution prior to unpackaging

and installation. The factory

should be notified of any

warranty repairs required in

21

General information

Summary of Contents for HC

Page 1: ...i Cooling Fresh Air Clean Air Heating Induction Unit Installation Operation and Maintenance...

Page 34: ......

Page 35: ......