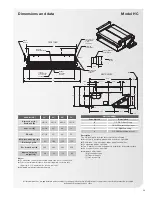

FRONT VIEW

D

E

3 1/16"

RETURN

SUPPLY

SUPPLY

RETURN

PRIMARY

AIR INLET

OPTIONAL

CONDENSATE PAN

WITH 11/16" DRAIN

ODF SWEAT

PLENUM

END PLUG

BALANCING

DAMPER

ADJUSTMENT

SEE CHART BELOW

FOR OPTIONAL

FITTINGS

OPTIONAL AIR VENT

AVAILABLE

OPTIONAL

ACCESSORY

LINT SCREEN

3 9/16"

4" O.D.

OPTIONAL TRANSITION

FITTING AVAILABLE

RIGHT SIDE VIEW

2 1/4"

7 1/4"

8 13/16"

3 1/2"

2 1/2"

3" MIN

4 1/2"

7 3/16"

13/16"

4 1/2"

22 7/8"

1 5/16"

1 1/4"

FLOOR

HEATING

COIL

COOLING

COIL

WALL

Dimensions and data

Model V4W

All listed dimensions are approximate and are subject to change without

notice. Modifications to the product specifications must be accepted

by Zehnder Rittling at its base office.

Notes:

Condensate connection mounted same side as cooling coil

connection

Shipping weight includes packaging

Orientation of coil conenctions to be determined

Inner coil is always for cooling and determines whether it is RH

or LH connections. Heating coil connections are opposite of cooling

connections

Description:

The V4W is shipped from the factory with the following:

Acoustically designed plenum and nozzles as specified

One 6-tube coil with copper tubes and aluminum fins

Condensate pan as specified

Coil connections as specified

Hardware kit includes:

(2) Leveling screws

(2) Leveling screw clips

(4) Lint screen clips

(2) Coil condensate plates with clips

Unit Size (V4W)

24"

32"

40"

52"

Dimensions (in.)

Drain pan (D)

29-3/8"

37-3/8"

45-3/8"

57-3/8"

Nom. coil (E)

24-1/8"

32"

40"

52"

Min. height from floor

3 inches

Min. free areas (sq. in.)

Discharge grille

81

108

135

175

Recirculation grille

237

315

394

512

Approx. shipping

weight (LB)

37

47

55

69

Optional fittings

Code digit #8

Description

0

1/2" ODF sweat fitting

1

1/2" ODF sweat fitting w/vent

2

1/2" ODM flare fitting

3

1/2" ODM flare fitting w/vent

17

Summary of Contents for HC

Page 1: ...i Cooling Fresh Air Clean Air Heating Induction Unit Installation Operation and Maintenance...

Page 34: ......

Page 35: ......