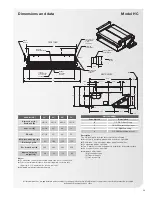

RIGHT SIDE VIEW

FRONT VIEW

D

3"

3"

E

F

PLENUM

END PLUG

OPTIONAL AIR

VENT AVAILABLE

SEE CHART BELOW

FOR OPTIONAL

FITTINGS

OPTIONAL

LINT SCREEN

AVAILABLE

OPTIONAL

CONDENSATE PAN

WITH 11/16" DRAIN

ODF SWEAT

SUPPLY

RETURN

BALANCING

DAMPER ADJUSTMENT

5/16" x 5/8" SLOTS IN

SUSPENSION MTG.

"Z" BARS

TYP (6) PLACES

3 1/2"

4 7/8"

4"

MIN

4 1/2"

3/4"

9 7/8"

10 5/16"

12 11/16"

3 3/16"

6 11/16"

6 11/16"

1"

13/16"

7 3/16"

TYP.

4 1/2"

TYP.

1 5/16"

5 1/4"

22 7/16"

14 1/4"

WALL

3 9/16"

4" O.D.

OPTIONAL TRANSITION

FITTING AVAILABLE

PRIMARY

AIR INLET

All listed dimensions are approximate and are subject to change without notice. Modifications to the product specifications must be accepted

by Hydro-Air at its base office.

Dimensions and data

Model H4C

Notes:

Condensate connection mounted same side as coil connection

Four inch minimum distance from wall required to obtain rated

capacity; 8-1/2" minimum for screen removal

Shipping weight includes packaging

Description:

The H4C is shipped from the factory with the following:

Acoustically designed plenum and nozzles as specified

Two 6-tube coils with copper tubes and aluminum fins

Condensate pan as specified

Two Z brackets for mounting unit to a rigid flat horizontal surface

Coil connections as specified

Hardware kit includes:

(8) Mounting screws

(8) Tinnerman nuts

(1) Lint screen clip

Unit size (H4C)

24"

32"

40"

52"

Dimensions (in.)

Drain pan (D)

30-1/4"

38-1/4"

46-1/4"

58-1/4"

Nom. coil (E)

24-1/8"

32"

40"

52"

Z Bar (F)

27-1/8"

35"

43"

55"

Min. free areas (sq. In.)

Discharge grille

81

108

135

175

Recirculation grille

234

288

343

439

Approx. shipping

weight (LB)

38

57

59

73

Optional fittings

Code digit #8

Description

0

1/2" ODF sweat fitting

1

1/2" ODF sweat fitting w/vent

2

1/2" ODM flare fitting

3

1/2" ODM flare fitting w/vent

12

Dimensions and data

Summary of Contents for HC

Page 1: ...i Cooling Fresh Air Clean Air Heating Induction Unit Installation Operation and Maintenance...

Page 34: ......

Page 35: ......