5 EPDT-192b

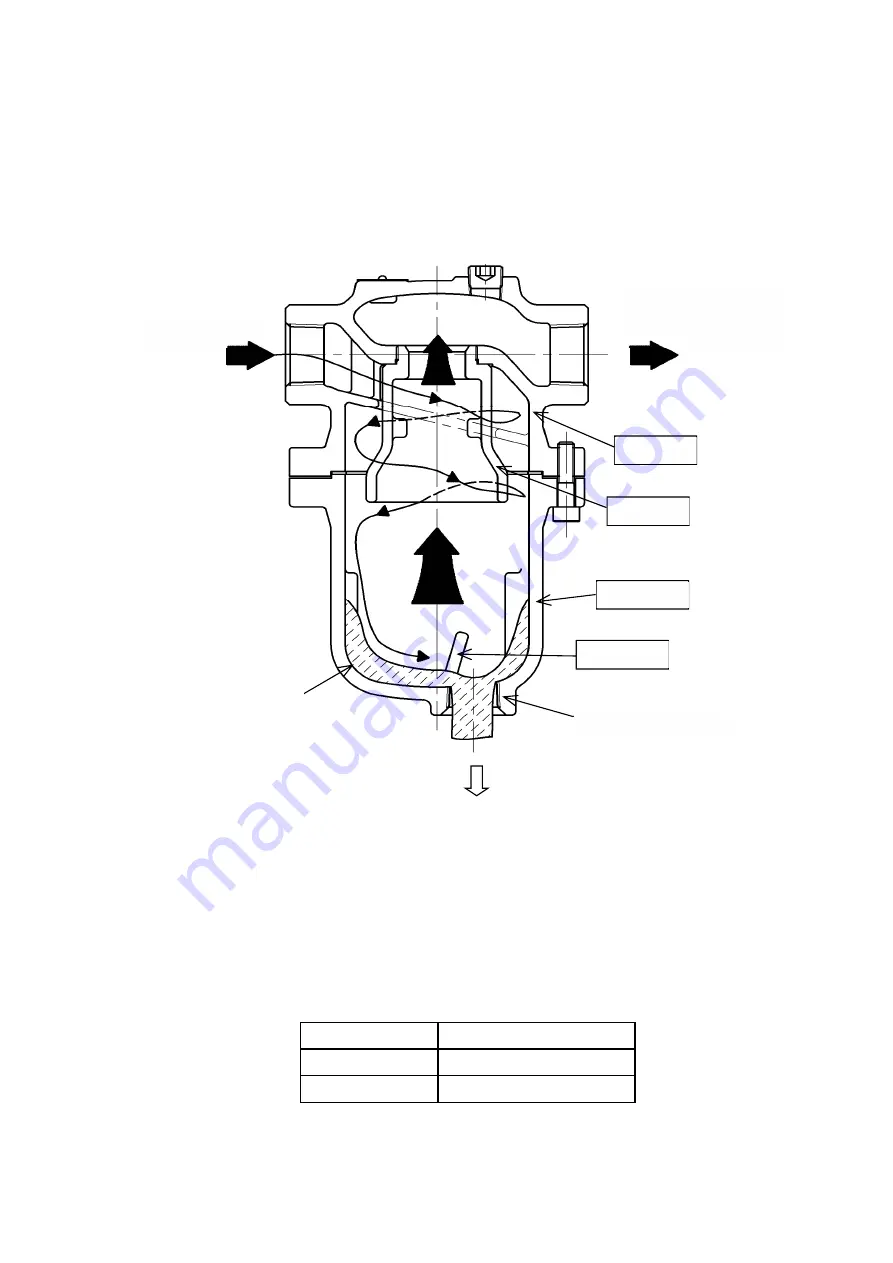

[Figure 3]

Steam or air

Receiver

Nozzle

Drain discharge port

Body

Drain

Clean and dry

steam or air

Baffle

4. Operation

The steam or air flow is subjected to a centrifugal force when it enters the drain separator. As soon as

steam or air flows into the drain separator, centrifugal force starts to work by the internal structure of the

body. Condensate swirls along the wall surface in consequence of the difference in specific gravity

between it and the steam or air, and strikes against the baffle. The condensate is then guided to discharge

port, while clean and dry steam or air flow to the outlet side through the nozzle.

5. Selection of nominal size

To make the best use of the drain separator and satisfy the operating requirements to the maximum,

take notice of the following.

[Selection of nominal size]

Select a nominal size equivalent to that of the pipe (piping nominal size = nominal size of drain

separator). Note that the use of a smaller nominal size increases the pressure loss through the drain

separator, possibly causing inadequate pressure at equipment inlet.

Table 1: Maximum flow velocity

Fluid

Maximum flow velocity

Steam

30 m/s

Air

15 m/s

*Use drain separator at less than maximum flow velocity.

*If flow velocity is too fast, the drain separator cannot function satisfactorily.