FORM 160.52-M2

YORK INTERNATIONAL

9

6. Using ENTRY keys, press “1” if the STANDBY

LUBRICATION feature, as described below, is

desired. Otherwise, press “0” .

7. Press ENTER key.

8. If FIXED SPEED oil pump application was se-

lected, by entering “0” in step 2 above, press PRO-

GRAM key to exit. Otherwise, press ADVANCE

DAY/SCROLL key.

OIL PRS CTRL PERIOD = __ x 0.3 SECONDS

is displayed.

9. Using ENTRY keys, enter desired value “1”

through “9”. Recommended value “3” will pro-

vide correct operation in most applications. If the

CANCEL key is pressed, default value “3” is dis-

played.

10. Press ENTER key.

11. Press ADVANCE DAY/SCROLL key.

OIL PRESSURE SETPOINT = XXPSID

is displayed.

12. Using ENTRY keys, enter desired value between

“20” and “45” PSID. Recommended value “35”

will provide correct operation in most applications.

If CANCEL key is pressed, default value “35” is

displayed.

13. Press ENTER key.

14. Press ADVANCE DAY/SCROLL key.

OIL PUMP VSD FREQUENCY = XX Hz

is displayed.

15. Using ENTRY keys, enter desired value between

“25” and “ 60” Hz. If CANCEL key is pressed,

default value “25” is displayed.

16. Press ENTER key.

17. Press PROGRAM key to exit.

MICRO BOARD CHANGES

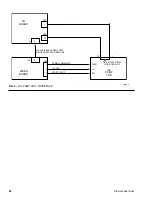

The VSOP drive’s PWM speed command input is gener-

ated on the Micro Board and is fed to the VSOP drive via

J10-2. J10-2 is not present on Micro Board part number

031-01065-001. The Micro Board has been revised to

include these circuits and the part number has been

changed to 031-01065-002. Micro Board part number

031-01065-002 is required on all VSOP drive applications.

STANDBY LUBRICATION

To maintain oil seal integrity while the chiller is shut

down, the oil pump is turned on for 2 minutes every 24

hours, if the chiller has not run in the past 24 hours.

While the pump is running,

STANDBY LUBE IN PROCESS - X.X MIN LEFT

is displayed. If a VSOP drive is installed, the operating

oil pressure will be the programmed oil pressure setpoint,

programmed by the Service Technician.

To prevent oil pump damage due to low oil level, if at

least 15 PSID of oil pressure is not achieved within 30

seconds of starting the oil pump, the cycle is terminated

and

STANDBY LUBE LOCKOUT- CHECK OIL LEVEL

is displayed when the STATUS key is pressed. No more

standby lubrication cycles will be performed until the

WARNING RESET key is pressed in SERVICE mode,

at which point another cycle will be attempted. Starting

the chiller also resets this STANDBY LUBE LOCK-

OUT.

Standby lubrication cycles will not be performed if either

oil pressure transducer is out of range (HOP < 6.8 PSIG;

LOP < 0 PSIG). No message will appear to indicate that

the lubrication cycle will not be performed. The verifica-

tion of correct pressure assures that standby lubrication

cycles will not be performed during maintenance of the

chiller or until the chiller has been charged with refriger-

ant and chiller commissioning has been completed.

These standby lubrication cycles are enabled or disabled

by the Service Technician using the VSOP drive selec-

tion procedure described above. It is recommended that

the standby lubrication be enabled on chillers that re-

main shut down for periods of 24 hours or greater.