FORM 150.24-NM27

YORK INTERNATIONAL

19

For installation in equipment rooms adjacent to or near

noise-critical areas, common walls should be of adequate

sound attenuating construction, all doors should be tightly

gasketed, and unit should have vibration isolators.

LOW AMBIENT LOCATIONS

The standard 350 watt crankcase heaters used with the

compressors are suitable for normal standby system

pressures and the ambient temperatures expected in an

indoor engine room heated in the winter. For unheated

engine rooms additional crankcase heat often is needed

to maintain crankcase oil temperatures at levels which

will prevent dilution of oil by the refrigerant to the point

that adequate lubrication on startup is endangered. A

crankcase temperature of 100°F to 120°F should be

maintained.

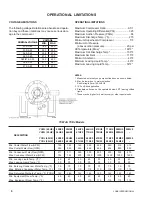

FOUNDATION AND MOUNTING

GROUND If the unit is to be located on an earth floor,

it should be placed on a level concrete slab extending 6"

to 8" above the level of the floor (see Fig. 4).

BASEMENT - Remove a portion of the basement floor

so that a concrete base can be poured resting on the

ground, extending 6" to 8" above the basement floor and

having sufficient space on all sides to install corkboard

as shown in Fig. 4.

FIG. 5

COMPRESSOR MOUNTING PAD

Vibration Isolators (Optional)

When ordered, four (4) vibration isolators will be furnished

with the unit. They are of the level adjusting spring type

and all four isolators are of identical capacity. They should

be mounted at the corners of the unit base as shown in

DIMENSIONS.

Fasten the isolator mounting bracket underneath the unit

base (It will be necessary to raise the unit to do this.)

Note that the bolt should be inserted from the bottom of

the mounting bracket.

FIG. 4

FOUNDATIONS

The isolator should be fastened to the mounting bracket

by the cap screw inserted through the hole in the mount-

ing bracket into the tapped hole in the top of the isolator

leveling bolt. Leveling of the unit is accomplished by turn-

ing the leveling bolt. After the unit is level, tighten the

cap screw.

COMPRESSOR MOUNTING

The compressors are mounted on (4) isolator pads (one

under each compressor foot). (See Fig. 5). The mount-

ing bolts are not to be loosened or adjusted at installation.

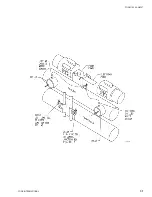

FIELD WATER PIPING

GENERAL When the unit has been located in its final

position, the unit liquid piping may be connected. Nor-

mal installation precautions should be observed in order

to receive maximum operating efficiencies. Piping should

be kept free of all foreign matter. All condenser and liq-

uid cooler piping must comply in all respects with local

plumbing codes and ordinances.

Since elbows, tees and valves decrease pump capacity,

all piping should be kept as simple as possible.

Hand stop valves should be installed in all lines to facili-

tate servicing.

Piping to the inlet and outlet connections of the chiller

and condenser may include high-pressure rubber hose

or piping loops to insure against transmission of vibra-

tion. This is optional and the necessary components must

be obtained in the field. The unit must not be subjected

to the weight of the connecting piping.

Drain connections should be provided at all low points to

permit complete drainage of condenser, liquid cooler and

piping system.

COMPRESSOR MOUNTING PAD

25112A

LD02350

Summary of Contents for YCRJ45E00

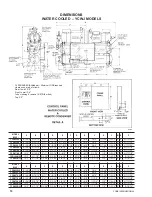

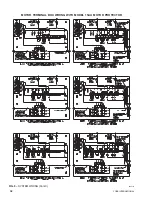

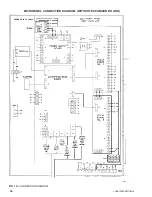

Page 29: ...FORM 150 24 NM27 YORK INTERNATIONAL 29 CONTROL CIRCUIT With I O Expansion Board LD02106 ...

Page 30: ...30 YORK INTERNATIONAL FIG 9 SYSTEM WIRING ...

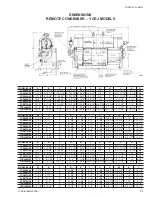

Page 31: ...FORM 150 24 NM27 YORK INTERNATIONAL 31 LD02678 ...

Page 35: ...FORM 150 24 NM27 YORK INTERNATIONAL 35 LD02679 ...

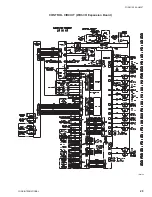

Page 36: ...36 YORK INTERNATIONAL MICROPANEL CONNECTION DIAGRAM With I O Expansion Board LD02107 ...

Page 37: ...FORM 150 24 NM27 YORK INTERNATIONAL 37 LD02108 ...