661693-UIM-E-1212

Johnson Controls Unitary Products

5

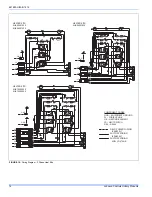

DUCT CONNECTIONS

Air supply and return may be handled in one of several ways best

suited to the installation. See Figure 2 for dimensions for duct inlet and

outlet connections.

The vast majority of problems encountered with combination heating

and cooling systems can be linked to improperly designed or installed

duct systems. It is therefore highly important to the success of an instal-

lation that the duct system be properly designed and installed.

Use flexible duct collars to minimize the transmission of vibration/noise

into the conditioned space. If electric heat is used, non-flammable

material must be used.

Where return air duct is short, or where sound may be a problem,

sound absorbing glass fiber should be used inside the duct. Insulation

of ductwork is a must where it runs through an unheated space during

the heating season or through an uncooled space during the cooling

season. The use of a vapor barrier is recommended to prevent absorp-

tion of moisture from the surrounding air into the insulation.

The supply air duct should be properly sized by use of a transition to

match unit opening. All ducts should be suspended using flexible hang-

ers and never fastened directly to the structure. This unit is not

designed for non-ducted (freeblow) applications. Size outlet plenum or

transition to discharge opening sizes shown in Figure 6.

Ductwork should be fabricated and installed in accordance with local

and/or national codes. This includes the standards of the National Fire

Protection Association for Installation of Air-Conditioning and Ventilat-

ing Systems, NFPA No. 90B.

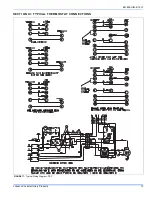

DUCTWORK TRANSITION

Ductwork that is not designed to match the supply air opening can

cause turbulence inside the plenum box. This turbulence can change

the air flow patterns across the heat kit limit switch. If the factory sug-

gested transition can not be fabricated, it is recommended a block off

plate (approximately 8” in height and running the full width of the ple-

num) be attached to the supply opening Please refer to Figure 8 as a

visual aid. The use of this block off plate will keep better air circulation

across the limit switch.

AIR FILTERS

Air filters must be field supplied. A 1" filter access rack has been built

into the unit. See Figure 2. Remove filter access cover shown. Install

proper size filter. Standard 1" size permanent or throw away filter may

be used, or, permanent washable filters are available using model num-

bers: 1PF0601, 602 or 603BK. See Table 2 for filter size.

.

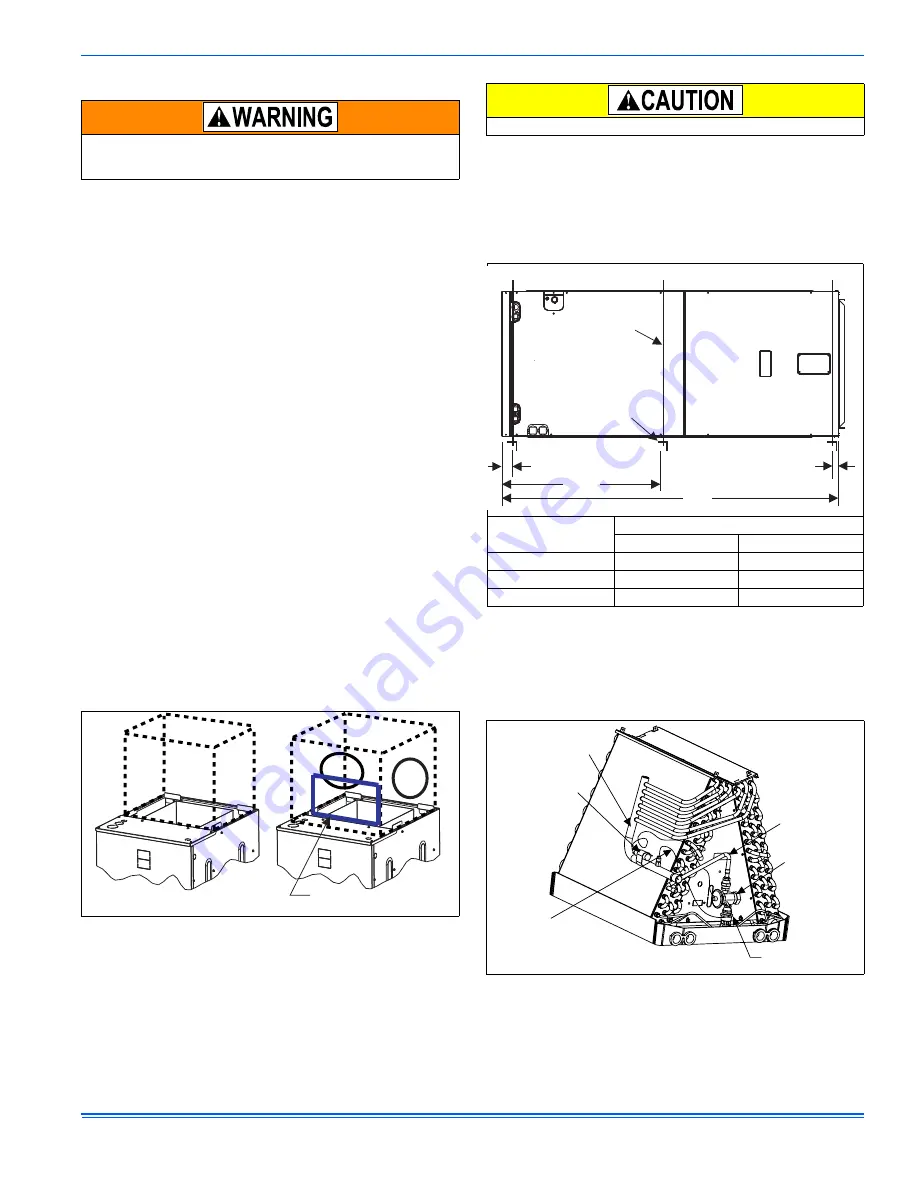

HORIZONTAL SUSPENSION

For suspension of these units in horizontal applications, it is recom-

mended to use angle steel support brackets with threaded rods, sup-

porting the units from the bottom, at the locations shown in Figure 9.

When an evaporator coil is installed in an attic or above a finished ceil-

ing, an auxiliary drain pan should be provided under the air handler as

is specified by most local building codes.

TXV METERING DEVICES

If the model number is of the following model series:

3X, the coil will require a R22 or R410A Orifice or TXV to be installed in

the field. Refer to installation manual with TXV kit. It is recommended to

install the TXV kit prior to brazing line sets.

Use 1/2" screws to connect ductwork to bottom of unit. Longer screws

will pierce the drain pan and cause leakage. If pilot holes are drilled,

drill only though field duct and unit bottom flange.

FIGURE 8:

Ductwork Transition

SUGGESTED LOCATION

OF BLOCK OFF PLATE

RECOMMENDED

TRANSITION

Equipment should never be operated without filters.

Units

(Nominal Tons)

Dimension

WW

XX

18, 24, 30, 36

20

46

42

24

52

48, 60

28

57

FIGURE 9:

Typical Horizontal Installation

FIGURE 10:

TXV

WW

XX

SUSPENSION SUPPORT LOCATIONS FOR HORIZONTAL APPLICATIONS

2

1-1/2

MIN. 1-1/2” x 1-1/2” Angle

Recommended length

26” minimum

with 2” clearance on

both sides of Air Handler

MIN. 3/8”

THREADED ROD

VAPOR

LINE

THERMAL

EXPANSION

VALVE BULB

THERMAL

EXPANSION

VALVE

DISTRIBUTOR

BODY

LIQUID

LINE

TXV

EQUALIZER

LINE

(Cover completely

with insulation

provided)

Summary of Contents for 41HP AHR18B

Page 1: ......