661693-UIM-E-1212

16

Johnson Controls Unitary Products

SECTION XII: START UP SHEET

Residential Air Handler

with Electric Heat Start-Up Sheet

Proper start-up is critical to customer comfort and equipment longevity

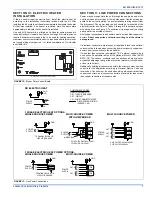

Other Jumpers

(Check all that apply)

Equipment Data

Blower Type

&

Set-Up

A

B

C

D

A

B

C

D

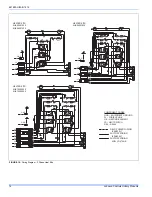

Total external static pressure

Supply

Return

Condensate drain properly connected per the installation instructions

Condensate trap has been primed with water

Duct connections are complete:

Number of filters

Filter size

Unit is level

Filters installed

Retrofit

New Construction

Down flow

Up flow

Horizontal Left

Horizontal Right

Ground connected

Start-Up Technician

Company Name

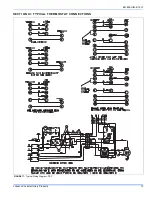

208 volts AC

230 volt AC

Line Voltage Measured (Volts AC)

Supply static (inches of water column)

Supply air dry bulb temperature

Return air dry bulb temperature

Temperature drop

1

2

3

4

5

Low

Medium Low

Medium

Medium High

High

A

B

C

D

Outside air dry bulb temperature

Return air wet bulb temperature

Supply air wet bulb temperature

Return static (inches of water column)

Electrical Connections & Inspection

(Complete all that apply)

Continued on next Page

ECM

X-13

PSC

A

B

C

D

Low voltage value between "R" and "C" at control board (Volts AC)

Thermostat wiring is complete

Thermostat cycle rate or heat anticipator adjusted to Installation Manual specifications

AC

HP

M

L

H

NO

YES

Equipment Data

Air Flow Setup

COOL

ADJUST

DELAY

HEAT

HUM STAT

AC/HP

CONT FAN

Name

Address

City

State or Province

Zip or Postal Code

Daytime Phone

Unit Model #

Unit Serial #

Transformer wired properly for primary supply voltage

Inspect wires and electrical connections

Unit Location and Connections

(Check all that apply)

General Information

(Check all that apply)

Start-Up Date

Filters

Owner Information

Print Form

Reset Form

Summary of Contents for 41HP AHR18B

Page 1: ......