5052617-UIM-E-1116

Johnson Controls Unitary Products

33

After about 5 minutes of operation, determine the furnace temperature

rise. Take readings of both the return air and the heated air in the ducts,

about six feet (1.83 m) from the furnace where they will not be affected

by radiant heat. Increase the blower speed to decrease the temperature

rise; decrease the blower speed to increase the rise. See furnace rating

plate for minimum or maximum temperature rise, and adjust blower

speed accordingly.

ADJUSTMENT OF FAN CONTROL SETTINGS

Heating Indoor Fan Off Delay

This furnace is equipped with a time-on/time-off heating fan control. The

fan on delay is fixed at 30 seconds. The fan off delay has 4 settings (60,

90, 120 and 180 seconds). The fan off delay is factory set to 120 sec-

onds. The fan-off setting must be long enough to adequately cool the

furnace, but not so long that cold air is blown into the heated space.

The BLOWER OFF DELAY timing may be adjusted by positioning the

dipswitches shown in Figure 40.

This furnace is equipped with a standard ECM motor. Blower motor

speed taps are located on the furnace control board in the blower com-

partment.

Refer to Figure 40 and the unit wiring diagram label to change blower

speed. Place all unused motor leads on the PARK terminal. One park

terminal is provided. To use same speed tap for heating and cooling,

the terminals must be jumped together at the furnace control board

using a field supplied jumper. This control has a continuous fan speed

dipswitch. On a fan call only (G), the control will energize which ever

blower tap is selected by dipswitches. This control will change other

blower speeds on 24V thermostat inputs (Y1, Y/Y2, W, W2).

TAKING A FLUE GAS SAMPLE

If it becomes necessary to obtain a flue gas sample for analysis, it is

permissible to drill a small hole in the plastic flue pipe for a sample

probe, provided that the vent piping is PVC and the hole is properly

sealed afterwards. If using a polypropylene vent system, the vent sys-

tems manufacturer test port fitting must be used. DONOT drill a test

port hole in polypropylene piping. Use the following procedure:

1.

Drill a 11/32" hole in the side wall of the PVC vent pipe. If the hole is

in a horizontal section of the vent pipe, ensure that it is located

away from the bottom where condensation may be flowing back

toward the furnace.

2.

Operate the furnace a minimum of (10 minutes) to ensure stable

operation of the combustion process.

3.

Sample the flue gas as necessary to obtain CO readings.

4.

Using a 1/8" pipe tap, cut threads into the sampling hole of the PVC

pipe.

5.

Use high temp RTV as a sealant on the threads of a 1/8" brass

MPT plug and insert it 3 turns into the hole to correctly seal it.

EXTERNAL STATIC PRESSURE SETUP

Set appropriate airflow per temperature rise for gas heating. Set appro-

priate airflow per Table 14 for cooling/heat pump heating operating

based on outdoor unit size.

To measure external static pressure:

•

Measure the supply air static pressure

•

Record this positive number

•

Measure the return air static pressure

•

Record this negative number

•

Treat the negative number as a positive and add the two num-

bers together

•

This is total system static

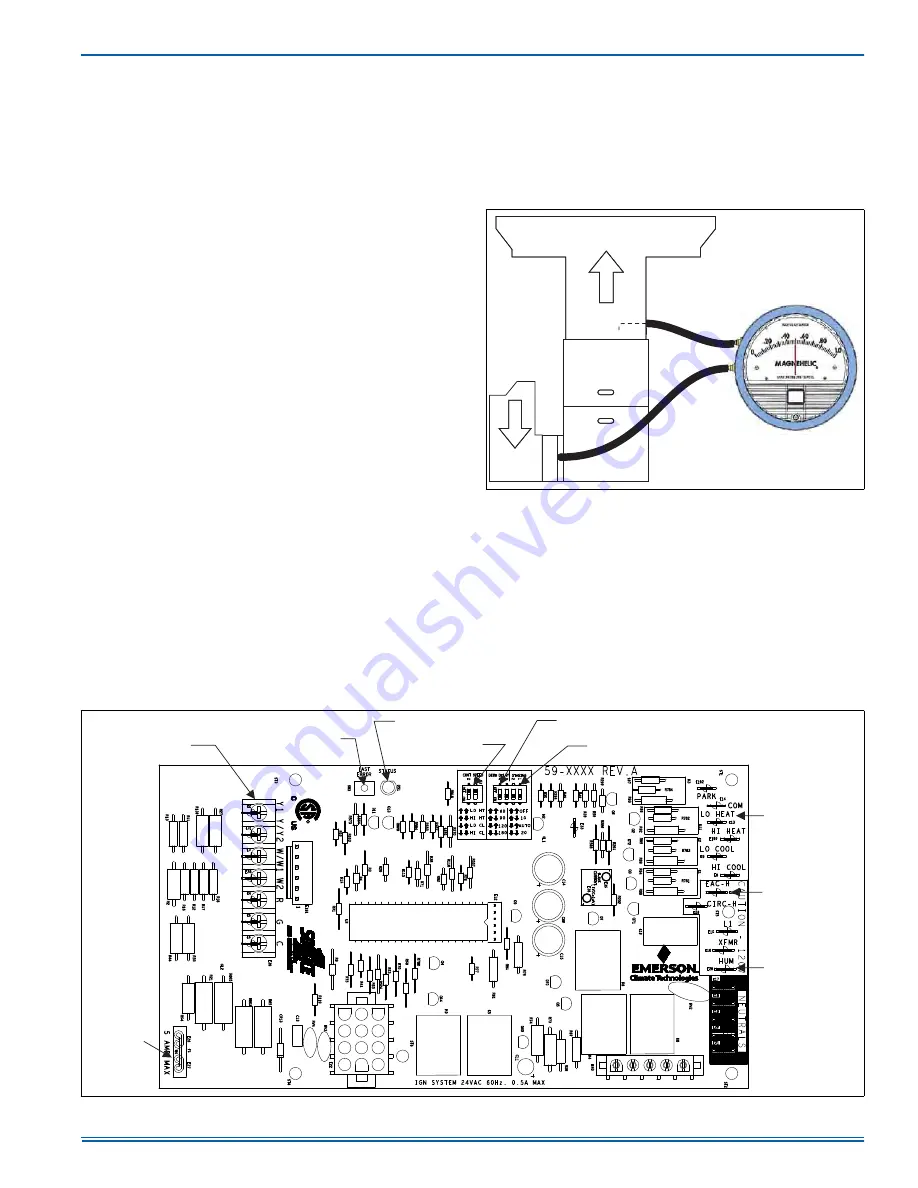

FIGURE 39:

Measuring External Duct Static

S

upply Duct

Return

Duct

FIGURE 40:

Furnace Control Board

&219(17,21$//2:

92/7$*(7+(50267$7

&211(&7,216

',$*1267,&/,*+7

',$*1267,&(5525

&2'(5(75,(9$/

%87721

&217,18286)$1

63(('',36:,7&+(6

%/2:(52))'(/$<

6(77,1*',36:,7&+(6

+,*+/2:),5(

67$*,1*',36:,7&+(6

(/(&7521,&

$,5&/($1(5

7(50,1$/

+80,',),(5

7(50,1$/

$

%/2:(5

02725

/2:92/7$*(

&211(&7256

&21752/

%2$5'

)86(