IM 05P02C41-15EN page 10/14

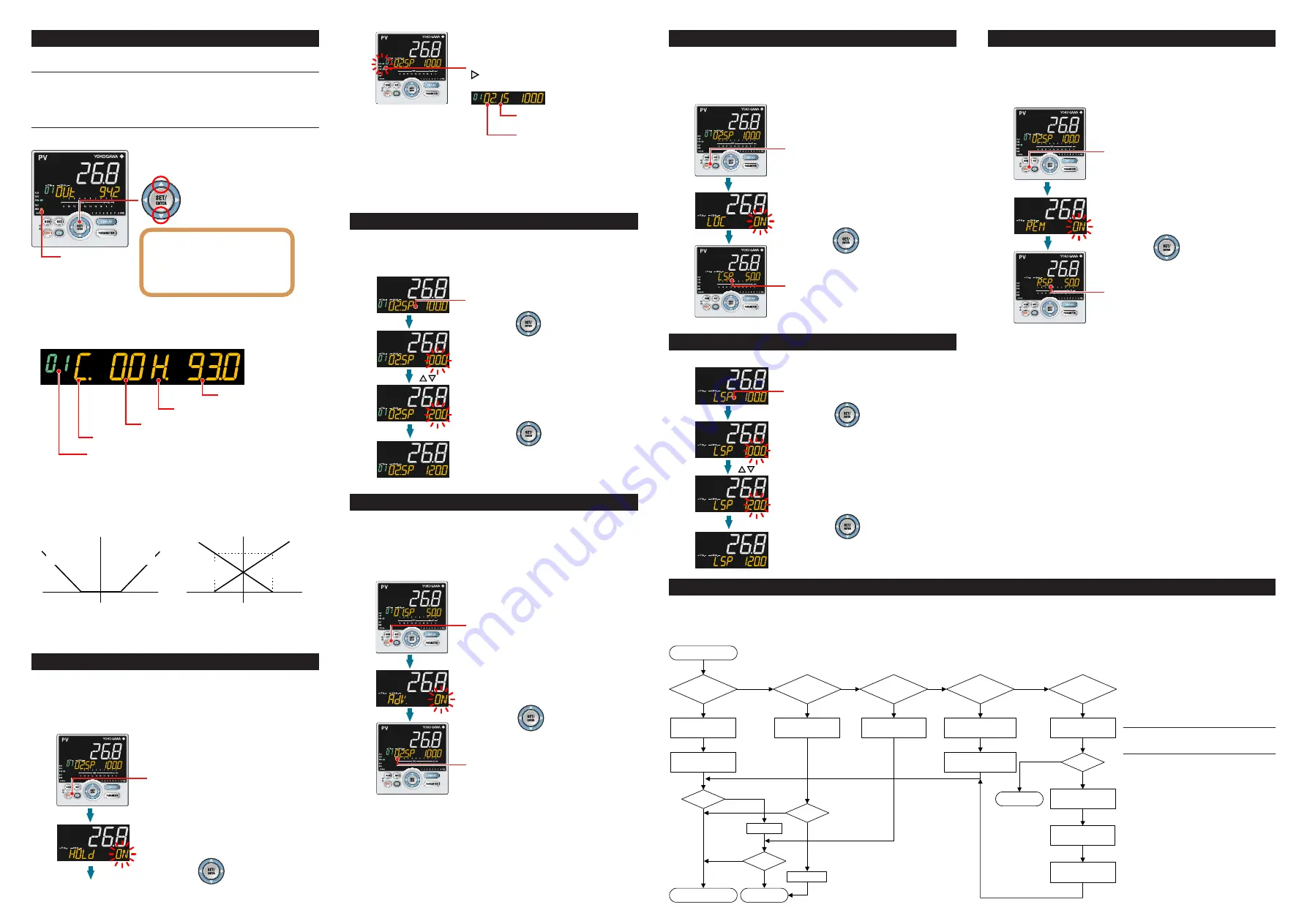

6. Manipulating Control Output in Manual Mode

NOTE

In manual mode, control output is manipulated by operating the keys (the value is

changed using the Up/Down arrow keys, then outputted as it is).

Even if the SET/ENTER key is not pressed, the control output value changes ac-

cording to the displayed value.

In stop mode (when the RST lamp is lit), control output cannot be manipulated.

MAN lamp is lit.

Up arrow key: increases control output.

Down arrow key: decreases control output.

In Position proportional control:

Up arrow key; opens the valve.

Down arrow key; closes the valve.

Output; only while pressing a key.

OUT; valve opening (0-100%)

Output manipulation in Position proportional control

is not restricted from output limiters (OH, OL).

Manual operation in Heating/cooling control

Symbol of cooling side

Program pattern (PTNO.) number

Symbol of heating side

Heating-side control output

Cooling-side control output

Up arrow key: concurrently decreases cooling-side control output and increases

heating-side control output.

Down arrow key: concurrently increases cooling-side control output and decreases

heating-side control output.

(Either none of the heating-side and cooling-side outputs are presented, or both of

them are presented according to the dead band setting.)

Actual output (%)

DB=24.8

Dead band: Operation parameter DB

Control computation output

Control computation output

12.4

0

-12.4

Manipulated output change

when a dead band is positive (+)

Actual output (%)

100

DB= -24.8

12.4

0

-12.4

Manipulated output change

when a dead band is negative (-)

100

Cooling-side

manipulated output

Heating-side

manipulated output

Heating-side

manipulated output

Cooling-side

manipulated output

7. Enabling/Disabling Hold Mode of Program Operation

Enabling/disabling hold mode of program operation can be performed during pro-

gram operation using any of the following: (1) MODE key, (2) Parameter, (3) Contact

input, and (4) Communication.

The following shows an example of switching using the MODE key.

1.

2.

3.

4.

Show the Operation Display.

Press the MODE key.

The number of segments included

in the selected program pattern.

The segment number for which

operation is in progress.

The figure below is displayed while the right

arrow key hold down.

Displays ”HOLD ON” in PROG mode.

Displays ”HOLD OFF” in HOLD mode.

HLD lamp is lit in HOLD mode.

Press the SET/ENTER key.

The parameter HOLD (Pause/cancel release

of program operation) is displayed (during

program operation.)

1.

2.

3.

4.

Show the Operation Display.

Press the MODE key.

The number of segments included

in the selected program pattern.

The segment number for which

operation is in progress.

The figure below is displayed while the right

arrow key hold down.

Displays ”HOLD ON” in PROG mode.

Displays ”HOLD OFF” in HOLD mode.

HLD lamp is lit in HOLD mode.

Press the SET/ENTER key.

The parameter HOLD (Pause/cancel release

of program operation) is displayed (during

program operation.)

Other operating procedures for disabling the hold mode:

(1) Press the RUN key for 1 second during hold-mode operation. In this case, the

controller resumes program operation.

(2) Execute the “Advance“ function during hold-mode operation. In this case, the

segment is advanced.

. Changing Program Setpoints when in Hold Mode

The following operating procedures changes a program setpoint of soak segment

during Hold-mode operation.

The program operation is started when releasing the Hold after changing the pro-

gram setpoint.

1.

2.

Set program operation in hold mode.

3.

4.

Blinks during the change.

Blinks during the change.

Press the SET/ENTER key.

Press the SET/ENTER key.

Press the Up/Down arrow keys to display the required setpoint.

9. Executing “Advance” Function

“Advance” can be performed during program operation using any of the following: (1)

MODE key, (2) Parameter, (3) Contact input, and (4) Communication.

The following shows an example of switching using the MODE key.

When executing the “Advance” function during hold-mode operation, the hold mode

is disabled.

1.

2.

3.

4.

The segment is advanced.

Press the SET/ENTER key.

Show the Operation Display.

Press the MODE key.

The ADV (Advance of segment) is displayed (during

program operation.)

10. Switching to Local-mode (LOCAL) Operation

Switching to local-mode can be performed using any of the following:

(1) MODE key (user function key), (2) Parameter, (3) Contact input, and (4) Commu-

nication.

The following shows an example of switching using the MODE key.

1.

2.

3.

4.

“LSP” is displayed when in

local-mode operation.

Press the SET/ENTER key.

Show the Operation Display.

Press the MODE key several times.

The LOC (local operation) is displayed.

11. Changing Setpoints during Local-mode Operation

The following operating procedures changes setpoints during local-mode operation.

1.

2.

3.

4.

“LSP” is displayed when in local-mode operation.

Press the SET/ENTER key.

Press the SET/ENTER key.

Blinks during the change.

Blinks during the change.

Press the Up/Down arrow keys to display the required setpoint.

13. Troubleshooting

■

Remedies if Power Failure Occurs

during Operations

• Instantaneous power failure within 20 ms.

A power failure is not detected. Normal

operation continues.

• Power failure for less than about 5 seconds,

or for about 5 seconds or more.

Affects the "settings" and "operation sta-

tus."

For details, see User's Manual.

NOTE

Write down the settings of parameters for a

repair request.

■ For the Errors at Power On

and the Errors during Op-

eration, see “Installation”

in this manual.

12. Switching to Remote-mode (REM) Operation

Switching to remote-mode can be performed using any of the following:

(1) MODE key (user function key), (2) Parameter, (3) Contact input, and (4) Commu-

nication.

The following shows an example of switching using the MODE key.

1.

2.

3.

4.

“R.SP” is displayed when in

remote-mode operation.

Press the SET/ENTER key.

Show the Operation Display.

Press the MODE key several times.

The REM (remote operation) is displayed.

■ Troubleshooting Flow

If the Operation Display does not appear after turning on the controller’s power, check the procedures in the following flowchart.

If a problem appears to be complicated, contact our sales representatives.

Is the controller

defective?

Contact us for repair. Problem solved.

No communication

capability

Completely

inactive?

Yes

Yes

Yes

No

No

No

Key

operation

failure?

Yes

No

Yes

Check wiring of the

power terminals.

Check the key lock

setting.

Display

failure?

*

Yes

No

Turn off power, and

then turn it on again.

I/O signal

failure?

Yes

No

Check the

supply voltage.

Check the

specifications and polarity

of connected devices .

Check the communication-

related parameters.

Check the specifications

of communication

devices.

Check the

communication wiring.

Communication

failure?

No

With

communi-

cation?

Yes

Yes

Normal?

Is the

key locked?

Check the specifications

of the controller.

Yes

No

Correct?

Correct the error(s).

Cancel the setting.

Check the I/O specifications

of the controller.

* The LCD (a liquid crystal display) is used for

a display portion of this product.

The LCD has a characteristic that the display action

becomes late at the low temperature.

Additionally, the luminance and contrast degradation

are caused due to aged deterioration.

However, the control function is not affected.