20

***Installation Guide

– Case IH Series Hydraulic Compressor

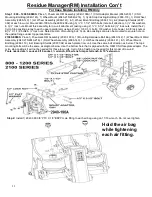

STEP 1: RESIDUE MANAGER (RM) OR RM/COULTER COMBO INSTALLATION

Residue Manager Only:

Install RM Assemblies securing with mounting hardware. Install the wheel mount assembly on the adjustment tube

so the top hole of the wheel mount aligns to the 4

th

or 5

th

hole down from the top of the adjustment tube for conventional tillage/mellow soils,

5

th

or 6

th

hole from the top for no till/minimum till conditions. Install wheels on wheel mounts using hardware from the 2966-119 bolt bag.

Install the RM wheels so that the left wheel leads, right wheel trails on the left side of planter; the right wheel leads, left wheel trails on right

side of planter.

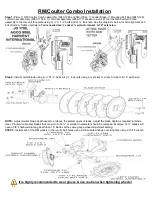

RM/Coulter Combo:

Install the RM/Coulter Combo assembly using hardware from the 2940-128 bolt bag. Mount the coulter blade on the

coulter arm hub & mount the RM wheels using the 5/8 Whiz Lock Nuts. RM wheels on combo units will install in the rear holes on both sides

on all rows. It is recommended to set the coulter blade at seed depth or above.

Refer to diagram on pages 20

– 23

STEP 2: TABLET/ISOBUS IN-CAB INSTALLATION

If using a tablet, mount Tablet & 2940-111 RAM Mount in tractor cab. Position Tablet within reach during operation without compromising

safety/visibility from cab. The right rear corner post area is recommended so that the operator can see performance of residue managers

while making adjustments. In both applications, install 2940-153A harness by feeding the bare ends thru the harness access hole into the

cab. Bare ends get spliced to plug (not provided) that fits

tractor’s switched power source, splice red wire on 2940-153A to orange wire &

splice black wires together on each harness. Leave the 2 pin connector at the tractor hitch.

Refer to diagram on page 24

STEP 3: 2940-103A CONTROL BOX INSTALLATION

Mount control box in a safe location with mounts & hardware supplied. Mount the 2940-415 water separator/regulator assembly near control

box. Locate hydraulic compressor & drain all tank pressure. Plumbing in to the compressor can happen by A) installing a 2940-408 3/8PTC

elbow fitting in the bung on the side of tank, or B) find the 3/8 tubing that routes between the top of tank & valve manifold. Cut & install a

Tee into that airline. Measure & cut 2940-367 250psi rated airline & route from remaining port on the Tee to inlet fitting (water trap side) of

Yetter water separator/regulator assembly. Adjust regulator to only allow 100-120psi of clean, dry air beyond it. Measure & cut 2940-345

black airline from outlet fitting (regulator side) of water separator/regulator assembly to inlet fitting

of control box. Route provided ¼” airline

from the elbow on the bottom of the water separator/regulator assembly to the ¼”PTC fitting on the bottom of control box. Route ¼” airline

fro

m remaining ¼”PTC fitting on control box toward the ground, as this airline will dispense moisture.

Refer to diagram on pages 25 & 32

STEP 4: CONTROL BOX HARNESS INSTALLATION)

Install 2940-166 VDM power cable with 40A breaker on tractor battery on the correct terminals, red = po, black = negative

–. Connect

VDM power extension (2940-167 or 2940-168) & route to tractor hitch. Install the AUX PWR Harness, 2940-164A or 2940-165A. The 2 pin

connects to the 2940-153A from tractor cab, Anderson power connector connects to 8 gauge cable that routes to battery, & the black male 12

pin Deutsch connector connects to power harness connector on the side of the control box. If the 2940-103A control box is mounted at the back

of the planter, 2940-170A(10ft), 2940-171A(30ft), & 2940-430A(20ft) AUX PWR extensions will be needed.

Refer to diagram on page 24

ISOBUS HARNESS (IF APPLICABLE)

Install the 2940-655 harness to 2940-654 on Yetter control box. Use 2940-657 (15ft) & 2940-658

(30ft) extensions to reach where the ISOBUS is being tied in. On JD planters, use the 2940-659 to plug in at the back of planter where

terminating resister harness was located. On RCM I Ag Leader systems, plug into the ISOBUS connections near the center of the planter at

the Planter Control Module using the 2940-662 harness. On RCM II Ag Leader systems, route to tractor hitch & plug into back of tractor

using 2940-656.

Refer to diagram on page 26

STEP 5: PLUMBING AIRLINES

A group of airlines that route to residue manager air bags are referred to as trunk airlines. Airline routing from RU, RD, & WT to trunk airline is

referred to as a supply airline. Start by routing trunk airlines: route black (down pressure) & blue (up pressure) airline on each wing/side of

planter. Start at end row of each wing, route airline to last row on wing & install in air bag, black airline = down pressure air bag, blue airline =

up pressure air bag. Follow airline back to end row cutting a tee in each airline at each row. When return back to end row, cut airline to length &

install into air bag. Install airline from each tee at each row & install in air bag for that row. If installing on a split row planter, keep trunk airline

on front rank residue managers on each wing plumbed separate from back rank. When plumbing in WT (wheel track) rows, use center 4 or 6

rows that plant over the tractor & planter wheel tracks. If equipping on a narrow transport planter with 4 center rows & 6 rows are desired on the

WT circuit, tie in the 1 row on each wing/side of the planter closest to the first & last center row. Install a tee in the center of each up pressure

trunk airline. Use tees to route/install blue airline from the RU port on control box to each tee in center of each up pressure trunk airline. Install a

tee into the down pressure trunk airline on the left wing & right wing. Route/install black airline from the RD port on control box to each tee in

center of left & right wing down pressure trunk airline. Install tee in center of center section down pressure trunk airline. Route/install airline from

WT port on control box to tee in the center of down pressure trunk airline on center of planter. If planter is dual rank, connect the trunk airline on

the corn rows to the trunk airline of the bean rows. Use 2940-342 ball valves between corn row trunk airlines & bean row trunk airlines to be

able to shut air supply off to bean rows when planting corn.

Refer to pages 32

– 47

STEP 6: PERFORM A PRE-OPERATION TEST OF THE SYSTEM

Now that the system is installed, perform a pre-operation test. Start by folding/unfolding & lowering/raising the planter checking for slack in

airline & in harnesses at hinge points. Check all electrical connections, cables, & airline making sure nothing was damaged. Next, with the

tractor on, connect to the WiFi with your tablet or pull the Yetter screen up on the ISOBUS VT, & press the ACTIVE SYSTEM icon. The

compressor will turn on, build to 145psi (100-120psi on the cab controller) & shut off. Check the interior of the control box housing (valve,

fittings, & airline) for leaks. Apply 40psi to the RU port & watch your RMs as they should all raise to maximum up travel. Check for leaks on all

up pressure circuits & fittings. When that leak check is finished, turn RU to 0psi & turn RD & WT to 40psi. Check all down pressure airline &

fittings in these circuits for leaks & repair as needed.

Refer to pages 53

– 54

Summary of Contents for GERMINATE UNIFORMITY 2940

Page 35: ...35 6 Row Airline Diagram 6 11 or 6 12 Split Row Airline Diagram...

Page 36: ...36 8 Row Airline Diagram 8 15 8 16 Split Row Airline Diagram...

Page 37: ...37 12 Row Airline Diagram...

Page 39: ...39 16 Row Airline Diagram...

Page 40: ...40 16 31 16 32 Split Row Airline Diagram...

Page 42: ...42 24 Row Airline Diagram...

Page 43: ...43 24 47 24 48 Row Airline Diagram...

Page 45: ...45 32 Row Airline Diagram...

Page 46: ...46 36 Row Airline Diagram...

Page 47: ...47 48 Row Airline Diagram...

Page 48: ...48 54 Row Airline Diagram...

Page 78: ...78 HYDRAULIC PUMP 2940 545 PARTS IDENTIFICATION PART REFERENCE ONLY...

Page 82: ...82 2565 983_REV_B 09 21...