WFC- SC(H) Series

.

Installation

- 10 -

A balance valve should be installed in the chilled-hot water outlet and a stop valve

should be installed in the chilled-hot water inlet. Both valves along with thermometer

wells should be placed in close proximity to the chiller-heater, refer figure 12.

After thoroughly testing for leaks, insulate the piping circuit ensuring an adequate

vapor barrier is obtained. Be sure the insulation allows proper access to all

thermometer wells and hand valves. Be also sure that the chiller-heater panels are not

restricted by the insulation.

If the equipment is installed outdoors and subject to freezing ambient conditions, trace

heating of the pipes under the insulation may be considered. If glycol solutions are

contemplated, it is important that inhibitors are in solution to protect copper tubes

internal to the machine. It is further most important to understand that cooling

capacity of the chiller-heater will be degraded as concentrations of the glycol

solutions increase – it must be noted that there is limited flow rate increase allowance

for the chilled- hot water circuit.

4.3

Cooling Water Piping

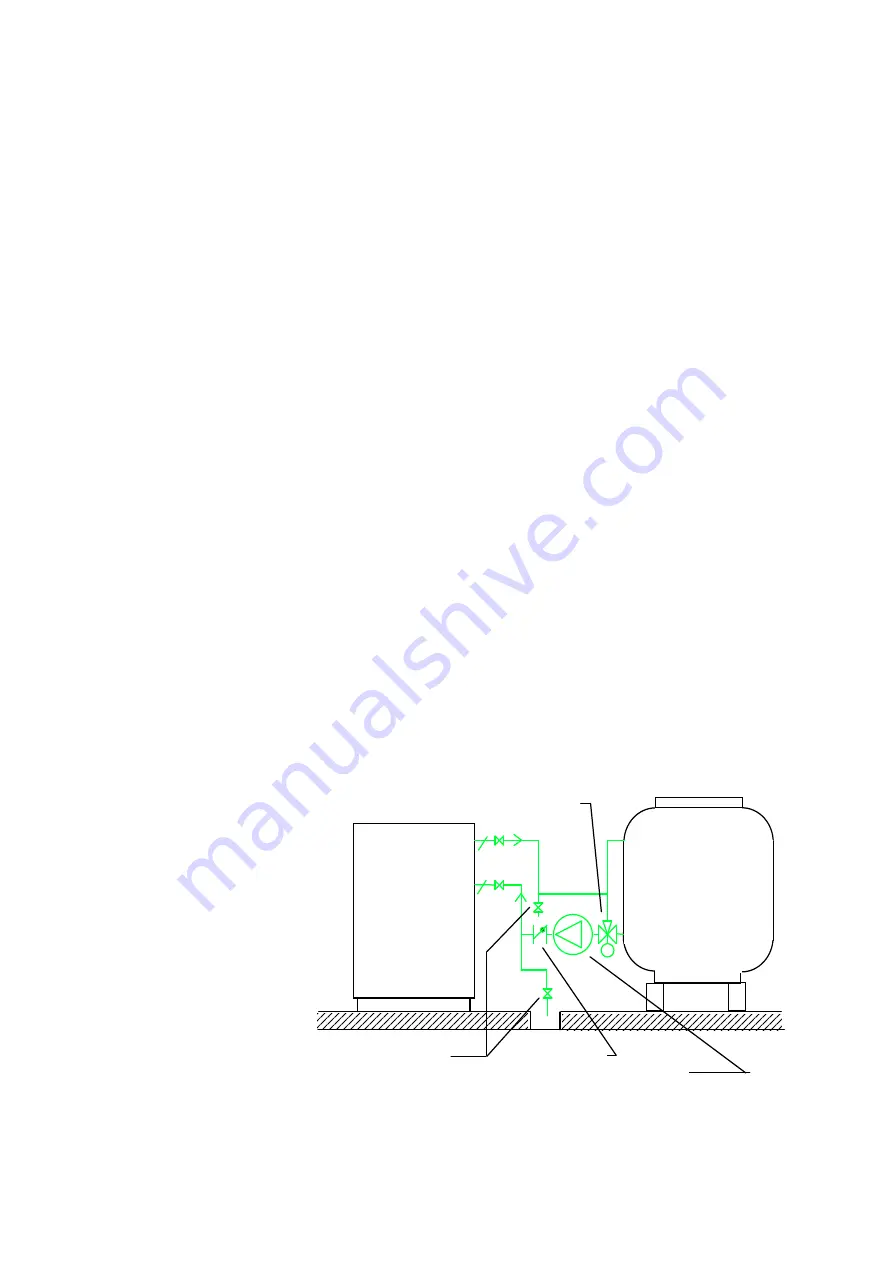

Cooling water to the absorption chiller-heater is required at a temperature of 31°C or

less during cooling operation. It is also imperative that cooling water less than 24°C

should not be supplied to the chiller-heater for prolonged periods.(longer than 30

minutes). If such contingency is likely to occur, a mixing valve facility must be

installed as illustrated in figure 13.

It is also of particular importance to observe that the cooling flows in a parallel

fashion through the WFC-SHC20 & SCH30 machines – dissimilar to the WFC-

SCH10 which flows in parallel. Attention must be paid to the instruction label on the

machine with respect to the sizing of the transfer pipe on the cooling water inlet.

Wherever possible, install the cooling tower at the same level or higher than the

chiller-heater. If it is not possible, give careful consideration to the prevention of

drain-back and loss of

cooling water due to

overflow at the tower.

Such matters should

have been given prior

consideration by the

design engineer along

with proper facility to

prevent damage to the

cooling

tower

fill

media as a result of

daily, frequent mode

change-over of the

chiller-heater.

F

Figure 13

Chiller-

Heater

Cooling

Tower

Mixing valve

Check valve

Cooling water

pump

Drain valves