9

*** Great care must be taken to ensure

that no oil enters the Yazaki chiller-

heater! Permanent damage could result

from even a small amount of oil being

introduced into the vacuum section! ***

Never

leave a vacuum pump running

unattended. Power loss could allow the

chiller-heater vacuum section to suck oil

out of the pump in a matter of seconds.

Never

have the Service Valve open

unless the vacuum pump is running and

the integrity of the vacuum lines between

the valve and the pump has been verified

as tight.

Never

have the vacuum pump discharge

tube in the water bucket unless the

vacuum pump is running. The vacuum

pump could suck water from the bucket

and contaminate the oil charge.

Never

pull

an

extended

vacuum

(exceeding a few hours)

. If such seems to

be necessary, there is likely to be

something wrong with the vacuum pump

or the oil has been contaminated with

moisture inherently found inside the

chiller-heater vacuum section.

Always

start with a fresh oil charge in the

vacuum pump.

Always

use a liquid trap or collection

flask.

Always

use a vacuum gauge to verify the

level of vacuum achieved. Run time has

almost nothing to do with the level of

vacuum achieved.

Use only dual-stage, deep vacuum

pumps. Typical refrigeration vacuum pumps

may not perform well on a vessel as large as

the chiller-heater

’s vacuum section. Just

because the vacuum pump has stopped

producing bubbles in the water bucket does

NOT mean the vacuum level is adequate. A

digital vacuum gauge MUST be used in

order to determine the true level of vacuum

achieved.

The desired level of vacuum on a

machine that is not running would be less

than 2000 microns

(<2 mmHg)

, with less than

1000 microns

(<1 mmHg)

preferred. On a

machine actively running in Cool mode

(currently attempting to satisfy chilled water loop

load)

, the desired level of vacuum is 4000-

5000 microns

(4-5 mmHg)

, no less. Any lower

than that on a running machine can cause

the

vacuum

pump

to

remove

an

extraordinary amount of refrigerant vapor

(water)

.

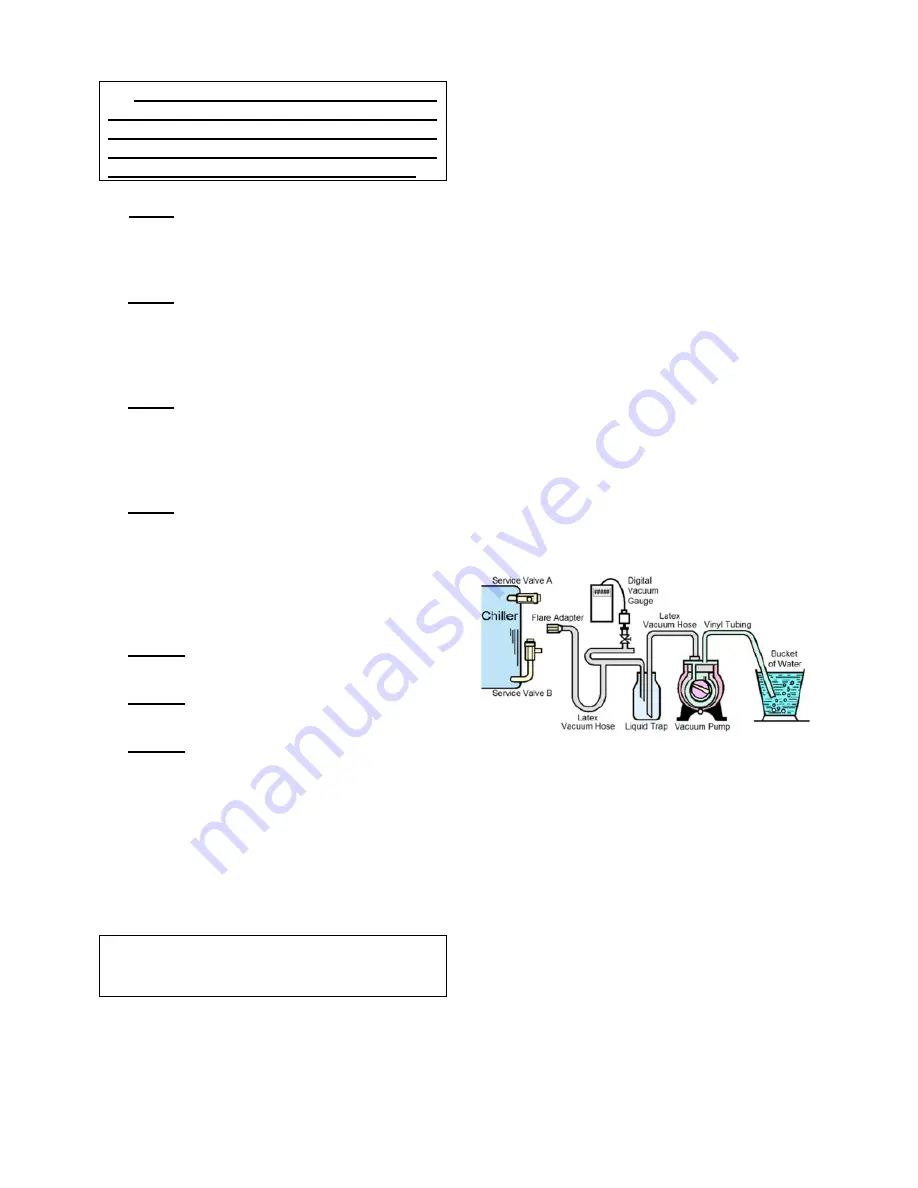

A

step-by-step,

detailed

evacuation

method is provided in the Service Manual.

The general evacuation assembly setup is

displayed in Figure 9.

Figure 9

– GENERAL EVACUATION

ASSEMBLY SETUP

CHEMICAL MAINTENANCE

It is not necessary to perform regular

chemical maintenance on the Yazaki

chiller-heater itself.

The

chemical

balance

has

been

established in the factory during run testing.

Normally, the only chemical that must be

maintained is the inhibitor charge. By

capturing

non-condensable

gases,

comparisons can be made to determine if

the normal hydrogen byproduct is being

produced at anticipated rates. If more

hydrogen is being produced than anticipated,

a maintenance inhibitor charge may need to

be introduced into the machine by the ASP.

An inhibitor charge is typically needed every

three

(3)

years in Yazaki gas-fired chiller-

heaters.

Summary of Contents for CH-K100

Page 15: ......