10

SHUTDOWN

The fluids within the chiller-heater itself

need no preparation for freezing conditions.

Only the fluids in the chilled water and

cooling water circuits need to be addressed

during potentially freezing conditions.

When the equipment is located outdoors

in climates subject to freezing, cooling water

should be drained from the chiller-heater,

fluid circuit piping, and cooling tower at the

end of the cooling season. Use glycol of

adequate concentration in the chilled water

and heat medium circuits to prevent freeze

damage. The glycol will reduce the cooling

and heating capacity but this may be offset

somewhat by increasing the circuit fluid flow

rate. If in doubt about potential freeze

damage in your area, discuss it with your

ASP. Damage to the unit due to freezing is

not covered by the product warranty.

If a unit is to be shut down for the winter,

but no fluid circuits are to be drained, then

simply Disable the chiller-heater and allow

the unit to complete its Post Dilution Cycle.

Once completed, it is safe to leave the unit

as it sits for the off-season. Take

appropriate measures to ensure the fluids in

all fluid circuits are protected from freezing

(glycol, heat tape, etc.)

.

If a chiller-heater is to be shut down long-

term, then fluid circuits should be drained.

Disable the chiller-heater and allow the unit

to complete its Post Dilution Cycle. Once

completed, turn off the breaker on the unit

control panel. Then drain each fluid circuit.

Once drained, make sure to blow in both

directions

through

each

circuit

with

compressed air

(or similar)

to make sure no

significant amount of liquid remains inside

them. Close all isolation valves so as to

isolate the unit from the rest of the respective

fluid circuit. Pressurize each fluid circuit in

the chiller-heater with dry nitrogen to a

pressure of 1-2 PSI (7-14 kPa) to help inhibit

corrosion in the circuit during storage. It may

be desirable to break the vacuum in the

chiller-heater itself as well. If doing so,

pressurize the unit to the same pressure as

the circuits using nitrogen. See the Service

Manual for further details.

TROUBLESHOOTING

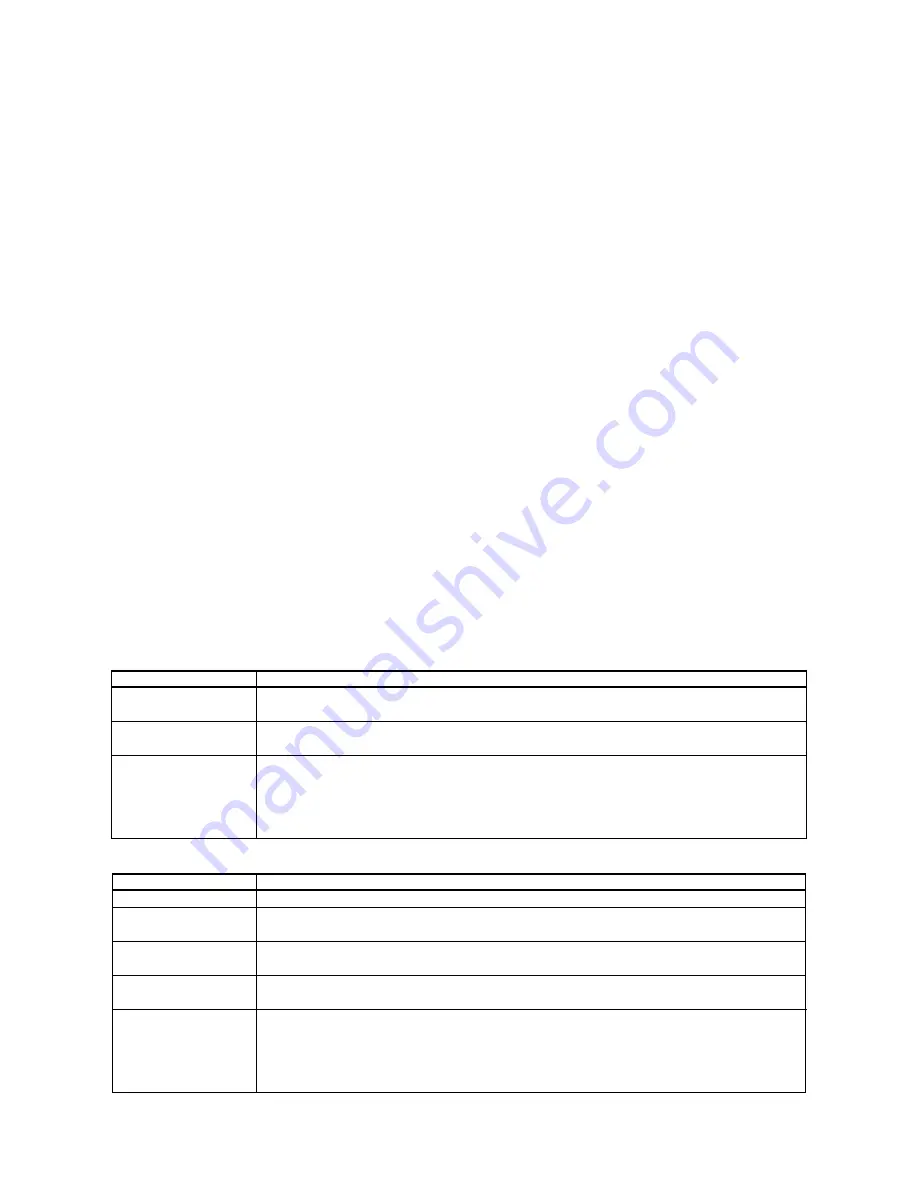

SYMPTOM: Chiller-heater does not operate.

Possible Cause

REMEDY

No High Voltage

Check the LED for the Power indication on the Control Panel. If it is not illuminated, check the

main power disconnect, fuses, and breakers.

Solution Pump Not

Running

Check the THRP overload switch. Check the GP temperature. Until the GP temperature rises

above 190°F

(88°C)

, the solution pump may remain off until the GP temperature warms up.

Chiller-heater is not

running but WTO

temperature is above

set point.

Nothing may be wrong. If the system chilled water loop has satisfied by reaching the desired set

point, the unit will shut down until the WTO sensor reads a temperature 3.6°F

(2°C)

above the set

point temperature, no matter how long that may take. To force operation, turn off power to the

chiller-heater, leave power off for 10 seconds, and then restore power. The chiller-heater should

start up if the WTO sensor reading is above the set point.

SYMPTOM: Poor cooling capacity.

Possible Cause

REMEDY

Poor Vacuum

Evacuate the machine per normal maintenance procedure. A leak check may also be necessary.

High Inlet Cooling

Water Temperature

Check the cooling tower fan. Check the cooling tower fluid level.

Low Cooling Water

Flow Rate

Check the cooling tower sump and cooling water circuit strainers.

Condenser/Absorber

Fouling, Scale Buildup

Check the cooling water circuit strainers. A chemical de-scaling procedure will be necessary.

Everything appears

normal but the leaving

chilled water

temperature is too

high.

Nothing may be wrong. If the load of the chilled water circuit exceeds the capacity of the chiller-

heater, the system will find equilibrium at a higher leaving chilled water temperature. If the

temperature drop through the chilled water loop is approximately 8-12°F

(4-6°C)

, then the unit

may actually be giving its full capacity and its capacity simply may not be enough. Check for

reasons that the load may have artificially increased

(open doors, new equipment, leaking valves, etc.)

Summary of Contents for CH-K100

Page 15: ......