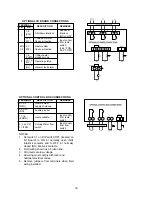

WATER QUALITY

NOTES:

ND = Not Detectable

*(Maximum total hardness of make-up water shall not exceed 70 ppm when bleed off is the only method

used to control water quality)

Table 2 WATER QUALITY REQUIREMENTS

INSTALLATION CHECK & REQUEST FOR START-UP

21

ITEM

pH (at 77

o

F)

Conductivity (µS/cm at 77

o

F)

Chloride ion (Cl

-

ppm)

Sulfate ion (SO

4

2-

ppm)

M-alkalinity (CaCO

3

ppm)

Total hardness (CaCO

3

ppm)

Calcium hardness (CaCO

3

ppm)

Ionic Silica (SiO

2

ppm)

Total iron (Fe ppm)

Copper (Cu ppm)

Sulfide ion (S

2-

ppm)

Ammonium ion (NH

4

+

ppm)

Residual chlorine (Cl ppm)

Free carbon dioxide (CO

2

ppm)

Ryzner stability index

Standar

d

Ref

erence

CHILLED/

HOT

WATER

6.8 - 8.0

400

50

50

50

70

50

30

1.0

1.0

ND

1.0

0.3

4.0

—

HEAT

MEDIUM

7.0 - 8.0

300

30

30

50

70

50

30

1.0

1.0

ND

0.1

0.1

0.4

—

COOLING

WATER

6.5 - 8.2

800

200

200

100

200*

150

50

1.0

0.3

ND

1.0

0.3

4.0

6.0 - 7.0

MAKE-UP

WATER

6.8 - 8.0

300

50

50

50

70

50

30

0.3

0.1

ND

0.1

0.3

4.0

—

Water used in the chilled/hot water, cooling

water and heat medium circuits may cause scal-

ing or corrosion if not correctly analyzed and

maintained within the limits specified in Table 2.

In some areas the water supply will contain

minerals that cause scaling or may be extremely

soft and corrosive. When these conditions exist a

water treatment company should be consulted.

If the absorption chiller is damaged as a result

of scaling, corrosion or erosion caused by poor

water quality control the equipment warranty is

voided.

The water quality in the chilled/hot water,

cooling water, and heat medium circuits shall not

exceed the following limits:

After the absorption chiller or chiller-heater

has been installed, piped and wired as described

in these instructions, but before any attempt is

made to start the unit, the Authorized Yazaki

Service Provider should be advised so that the

start-up can be scheduled.

Complete the

INSTALLATION CHECK AND REQUEST FOR

START-UP FORM and send to the Yazaki Sales

Representative or Distributor at least 2 weeks

prior to the required start-up date.

The contractor is expected to provide person-

nel to assist with final adjustment of system con-

trols and flow rates.