12

FOUNDATION

Mount the absorption chiller on a level floor or

foundation capable of supporting the operating

weight of the unit (refer to PHYSICAL DATA on

Page 3).

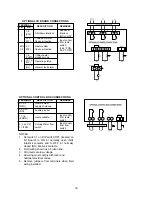

A concrete base, with dimensions shown in

Fig. 4, should be at least 12 in. thick and

reinforced with crushed rock or steel.

PLACEMENT

When the absorption chiller has been moved

into final position, remove the skid (if not already

removed). Place a spirit level on the level bar,

shown in Fig. 5, and insert stainless steel slotted

PIPING

GENERAL

After leveling the absorption chiller, the piping

for chilled/hot water, cooling water and heat

medium should be installed. Arrange the piping

with offsets so that it does not interfere with

removal of panels or service access to the

equipment. Adequately support and brace the

piping independently of the unit to avoid strain on

the pipe connections. Provide thermowells at each

inlet and outlet connection for measurement of

fluid temperatures during start-up and routine

maintenance (not required on cooling water

crossover piping).

CHILLED/HOT WATER PIPING

The chilled/hot water piping contains chilled

water during cooling operation and hot water

during heating operation and must be

adjustment plates (shims) between each

mounting plate and the foundation, as shown in

Fig. 6. Adjust the shim thickness for longitudinal

and transverse alignment of the absorption chiller.

pressurized, as shown in Fig. 7, by either an open

cistern or closed expansion tank. Install piping

with a rising grade of 1/200 and install manual

vent valves at high points to expel trapped air.

A balancing valve should be installed

adjacent to the chilled/hot water outlet on each

unit to facilitate flow rate adjustments within

specified limits. Install a stop valve adjacent to the

chilled/hot water inlet on each chiller. This valve

must be in the full open position when the

equipment is operating. DO NOT CLOSE the stop

valve except for disconnection or relocation of the

machine.

Insulate piping AFTER LEAK TESTING to

prevent heat transfer and sweating. Cover

insulation with a vapor barrier and ensure all stop

valves, balancing valves and thermowells are

accessible.

Fig. 4 FOUNDATION EXAMPLE

Fig. 5 LEVEL BAR

Fig. 6 ADJUSTMENT (SHIM) PLATE