Whenever the absorption chiller or the

chilled/hot water piping is installed outdoors and

subject to ambient temperatures below freezing,

the circuit should be filled with a glycol solution of

adequate concentration to prevent freezing. It is

important that the glycol solution contain

inhibitors to protect the copper tubes in the

absorption chiller from corrosion. If glycol is not

used for freeze protection, install a temperature

limit switch in the lowest outdoor section of the

HEAT MEDIUM PIPING

The heat medium piping contains water which

must be pressurized, as shown in Fig. 8, by either

an open cistern or closed expansion tank. Install

piping with a rising grade of 1/200 and install man-

ual vent valves at high points to expel trapped air.

A balancing valve should be installed adja-

cent to the heat medium outlet on each unit to

facilitate flow rate adjustments within specified

limits. Install a stop valve adjacent to the heat

medium inlet on each chiller. This valve must be in

the full open position when the equipment is

operating. DO NOT CLOSE the stop valve except

for disconnection or relocation of the machine.

Insulate piping AFTER LEAK TESTING to

prevent heat loss and ensure that all stop valves,

balancing valves and thermowells are accessible.

Whenever the absorption chiller or the heat

medium piping is installed outdoors and subject

to ambient temperatures below freezing, the

chilled/hot water pipe and interlock the switch with

the absorption chiller controls (refer to Optional

Field Wiring Connections).

circuit should be filled with a glycol solution of

adequate concentration to prevent freezing. It is

important that the glycol solution contain

inhibitors to protect the stainless steel tubes in

the absorption chiller from corrosion. If glycol is

not used for freeze protection, install a

temperature limit switch in the lowest outdoor

section of the heat medium pipe and interlock the

switch with the absorption chiller controls (refer to

Optional Field Wiring Connections).

Install a motorized 3-way bypass valve (HMV)

with limit switches to control the heat input to the

absorption chiller.

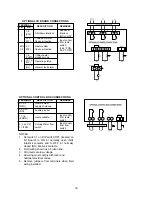

Fig. 8 HEAT MEDIUM PIPING

13

CAUTION

1. DO NOT EXCEED 80 - 120% OF

STANDARD CHILLED/HOT WATER FLOW.

2. DO NOT EXCEED 85.3 PSI IN THE

CHILLED/HOT WATER CIRCUIT AT THE

ABSORPTION CHILLER.

3. DO NOT INSTALL ANY VALVES IN THE

EXPANSION LINE.

CAUTION

1. DO NOT EXCEED 30 - 120% OF

STANDARD HEAT MEDIUM FLOW.

2. DO NOT EXCEED 85.3 PSI IN THE

HEAT MEDIUM CIRCUIT AT THE

ABSORPTION CHILLER.

3. DO NOT INSTALL ANY VALVES IN THE

EXPANSION LINE.

Heat Medium

Outlet

Heat Medium

Inlet

T

Drain

IF3 Switch (Optional)

Heat Medium Pump

Air Vent

Chiller/Chiller - Heater

T

Water Make-Up/

Expansion Line

Check/Reducing Valve

Expansion Tank

Relief Valve

Water Supply

Heat Medium Bypass Valve (HMV)

P

P

Fig. 7 CHILLED/HOT WATER PIPING

T

T

Chilled/Hot Water Pump

IF1 Switch (Optional)

Air Vent

Drain

Water Supply

Check/Reducing Valve

Expansion Tank

Relief Valve

Water Make-Up/

Expansion Line

Chilled/Hot Water

Outlet

Chilled/Hot Water

Inlet

Chiller/Chiller - Heater

P

P