NOTES:

1. Full Load Amps (FLA) marked on motor nameplate.

2. Use minimum 14 AWG copper conductors for absorption chiller power supply.

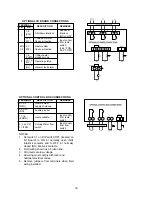

Table 1 ELECTRICAL DATA

MODEL

WFC-SC10

WFC-SH10

WFC-SC20

WFC-SH20

WFC-SC30

WFC-SH30

POWER

SUPPLY

(V)

208

208

208

SOLUTION PUMP

(3 PH)

OUTPUT

FLA

(HP)

(A)

1/8

0.46

1/6

0.75

1/3

2.04

POWER SUPPLY

MIN. CIRCUIT AMPS

MAX. FUSE SIZE

)

A

(

)

A

(

5

1

6

.

0

5

1

9

.

0

5

1

6

.

2

20

POWER WIRING

Select the disconnect, fuses and supply

conductors for each absorption chiller based on

the minimum circuit ampacity and maximum fuse

size on the UNIT NAMEPLATE as per the

Electrical Data in Table 1. Install conduit to the

field wiring junction box and leave sufficient clear-

ance for removal of panels and service access.

DO NOT attach conduit to the absorption chiller

cabinet. The 1/2 in. trade size conduit entry in the

junction box will accommodate four (3 live and 1

grounded) 14 AWG copper conductors in most

wire styles. DO NOT USE ALUMINUM

CONDUCTORS.

Locate the disconnect within sight of and

readily accessible to the equipment, per Section

440-14 of the National Electrical Code.

DO NOT CLOSE THE DISCONNECT until

approved by an Authorized Yazaki Service

Provider.

CONTROL WIRING

All field control wiring connections to the

absorption chiller are low voltage (less than 30 V

AC) class 2 circuits and may be installed with or

without conduit. A 1/2 in. trade size conduit should

be installed to protect the wire against physical

damage or for aesthetic reasons. If

conduit is not used, a bushing must be inserted

into the wire entries of the junction box. Route

additional wiring to the control box for optional

input and output controls through the absorption

chiller junction box.

Motor contactors and overload relays for the

chilled/hot water pump, cooling water pump, heat

medium pump and cooling tower fan are not

installed in the absorption chiller and must be

supplied by others. Refer to the relevant Field

Wiring Diagram (Single Module or Multiple

Modules) for the recommended wiring of these

controls.

Use 18 AWG type T wire or equivalent for all

low voltage field circuits up to 50 ft. (for longer

distances use a 16 AWG conductor).