8.2 Details on Standard I/O Profile Commands

8.2.1 Asynchronous Data Read/Write Command (DATA_RWA: 20 Hex)

8-10

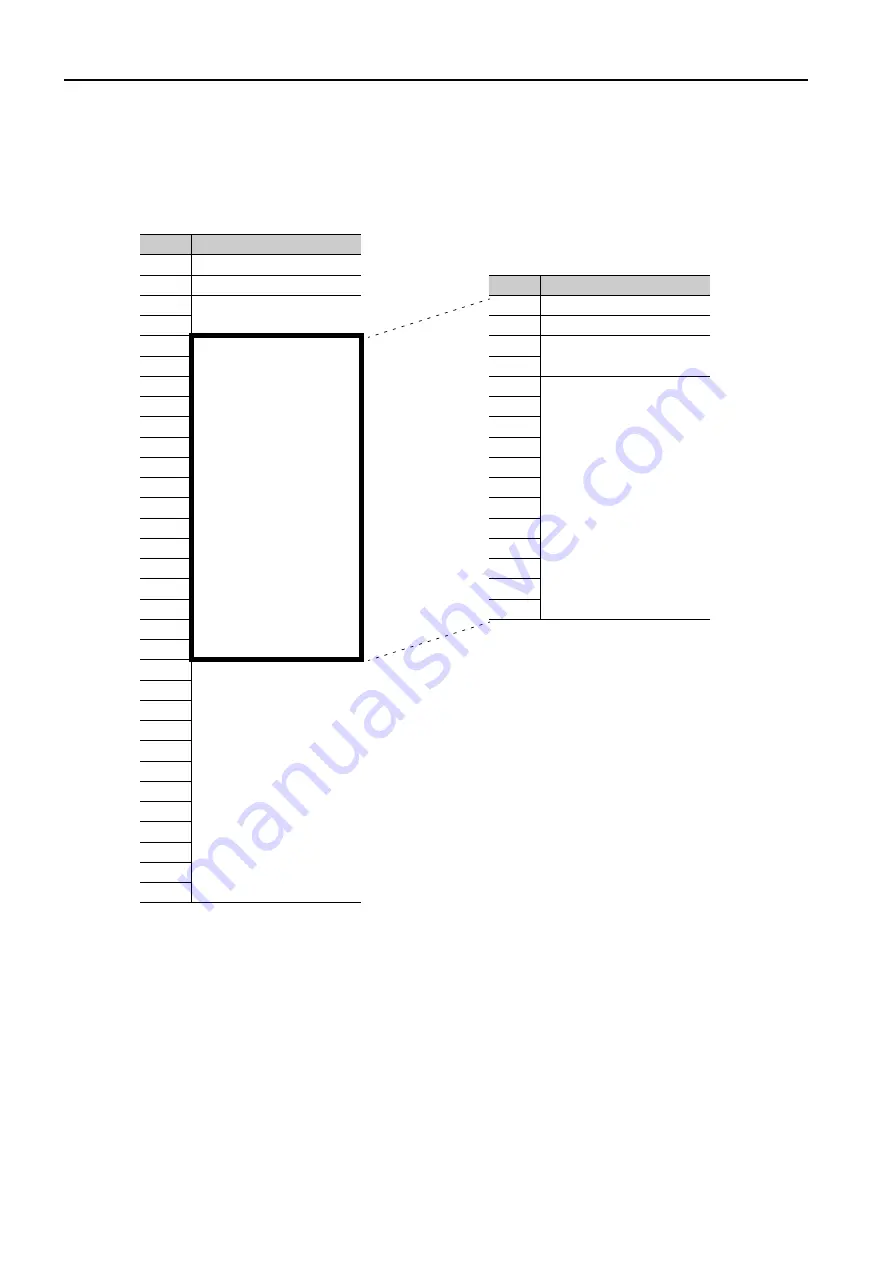

Response data

The response data area (in bold lines below) in the M-III response is used as a buffer memory

for the GW3100 to set the M-II response data.

The location of the M-II response data depends on a parameter setting.

In the same way as for commands, the response for more than one station can be stored.

Byte

M-III Response

0

DATA_RWA

1

RWDC

Byte

M-II Response

2

CMD_STAT

0

DATA_RWA

3

1

ALARM

4

Response data

2

STATUS

5

3

6

4

Response data

7

5

8

6

9

7

10

8

11

9

12

10

13

11

14

12

15

13

16

14

17

15

18

19

20

Response data

21

22

23

24

25

26

27

28

29

30

31