SK1050 Operator’s Manual

Service - 75

Procedures

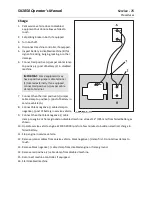

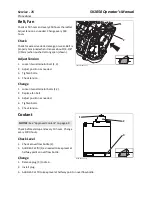

Charge

1. Park service vehicle close to disabled

equipment but do not allow vehicles to

touch.

2. Set parking brake in both, if equipped.

3. Turn both off.

4. Disconnect machine controller, if equipped.

5. Inspect battery in disabled machine (B) for

signs of cracking, bulging, leaking, or other

damage.

6. Connect red positive (+) jumper cable clamp

to positive (+) post of battery (2) in disabled

machine.

7. Connect the other red positive (+) jumper

cable clamp to positive (+) post of battery in

service vehicle (A).

8. Connect black negative (-) cable clamp to

negative (-) post of battery in service vehicle.

9. Connect the other black negative (-) cable

clamp to engine or frame ground on disabled machine, at least 12” (305 mm) from failed battery, as

shown.

10. Operate service vehicle engine at 1500-2000 rpm for a few minutes to build an electrical charge in

failed battery.

11. Stop engine in service vehicle.

12. Remove jumper cables from service vehicle, black negative (-) clamp first. Do not allow clamps to

touch.

13. Remove black negative (-) cable clamp from disabled engine or frame ground.

14. Remove red positive (+) cable clamp from disabled machine.

15. Reconnect machine controller, if equipped.

16. Start disabled machine.

IMPORTANT:

Some equipment may

have a positive jumper cable terminal

(1) located externally. If so equipped,

connect red positive (+) jumper cable

clamp to terminal.

Summary of Contents for SK1050

Page 1: ...SK1050 Yanmar 3TNV88C Operator s Manual CMW 053 2963 Issue 3 0 Original Instruction ...

Page 19: ...Safety Awareness 18 SK1050 Operator s Manual Machine Safety Alerts ...

Page 49: ...Controls 48 SK1050 Operator s Manual Operator Station ...

Page 55: ...Drive 54 SK1050 Operator s Manual Shut Down ...

Page 63: ...Transport 62 SK1050 Operator s Manual Retrieve ...

Page 89: ...Service 88 SK1050 Operator s Manual Procedures ...

Page 95: ...Specifications 94 SK1050 Operator s Manual Declaration of Conformity ...