5-19

FRONT FORK

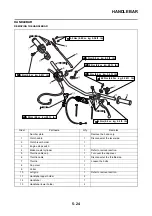

CHECKING THE BASE VALVE

1. Inspect:

• Base valve "1"

Wear/damage

→

Replace.

Contamination

→

Clean.

• O-ring "2"

Wear/damage

→

Replace.

• Piston metal "3"

Wear/damage

→

Replace.

• Spring "4"

Damage/fatigue

→

Replace base

valve.

• Air bleed screw "5"

Wear/damage

→

Replace.

CHECKING THE COLLAR

1. Inspect:

• Contacting surface "a"

Wear/damage

→

Replace.

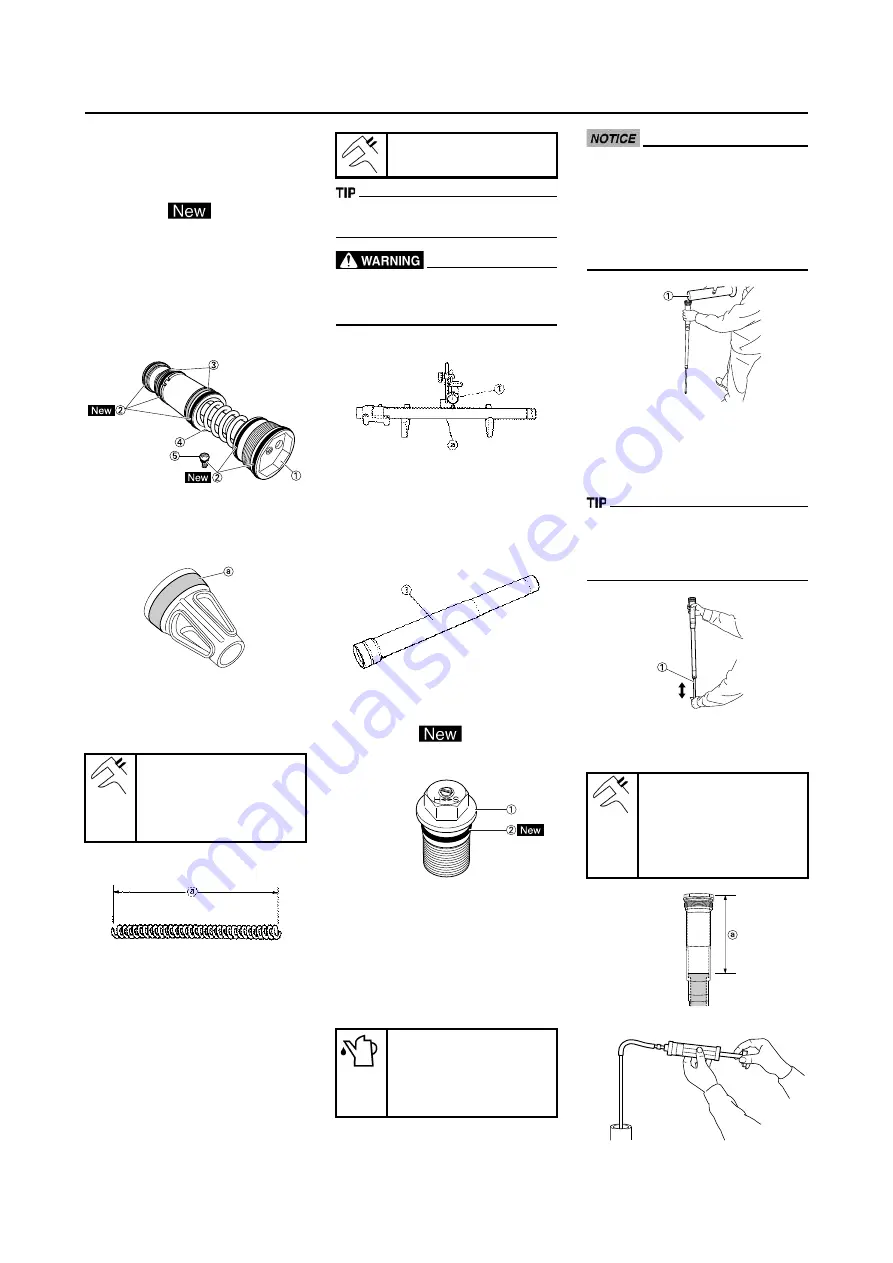

CHECKING THE FORK SPRING

1. Measure:

• Fork spring free length "a"

Out of specification

→

Replace.

CHECKING THE INNER TUBE

1. Inspect:

• Inner tube surface "a"

Score marks

→

Repair or replace.

Use #1,000 grit wet sandpaper.

Damaged oil lock piece

→

Re-

place.

• Inner tube bends

Out of specification

→

Replace.

Use the dial gauge "1".

The bending value is shown by one

half of the dial gauge reading.

Do not attempt to straighten a bent

inner tube as this may dangerous-

ly weaken the tube.

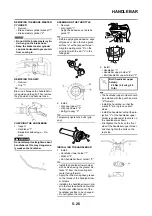

CHECKING THE OUTER TUBE

1. Inspect:

• Outer tube "1"

Score marks/wear/damage

→

Re-

place.

CHECKING THE ADJUSTER

1. Inspect:

• Adjuster "1"

• O-ring "2"

Wear/damage

→

Replace.

ASSEMBLING THE FRONT FORK

1. Wash the all parts in a clean sol-

vent.

2. Stretch the damper assembly ful-

ly.

3. Fill:

• Front fork oil "1"

To damper assembly.

• Be sure to use recommended

fork oil. If other oils are used,

they may have an excessively ad-

verse effect on the front fork per-

formance.

• Never allow foreign materials to

enter the front fork.

4. After filling, pump the damper as-

sembly "1" slowly up and down

(about 200 mm (7.9 in) stroke)

several times to bleed the damper

assembly of air.

Be careful not to excessive full stroke.

A stroke of 200 mm (7.9 in) or more

will cause air to enter. In this case, re-

peat the steps 2 to 4.

5. Measure:

• Oil level (left and right) "a"

Out of specification

→

Adjust.

Fork spring free length

"a":

454.0 mm (17.87 in)

<Limit>: 449.0 mm

(17.68 in)

Inner tube bending limit:

0.2 mm (0.01 in)

Recommended oil:

Suspension oil "S1"

Oil capacity:

203 cm

3

(7.15 Imp oz,

6.86 US oz)

Standard oil level "a":

145–148 mm (5.71–5.83

in)

From top of fully

stretched damper as-

sembly.

Summary of Contents for YZ125 2015

Page 4: ......

Page 12: ...1 2 LOCATION OF IMPORTANT LABELS EUROPE...

Page 13: ...1 3 LOCATION OF IMPORTANT LABELS AUS NZ ZA...

Page 61: ...3 18 CHASSIS...

Page 165: ......

Page 166: ...PRINTED IN JAPAN E PRINTED ON RECYCLED PAPER...