6-6

Chapter

6

PERIODIC INSPECTIONS

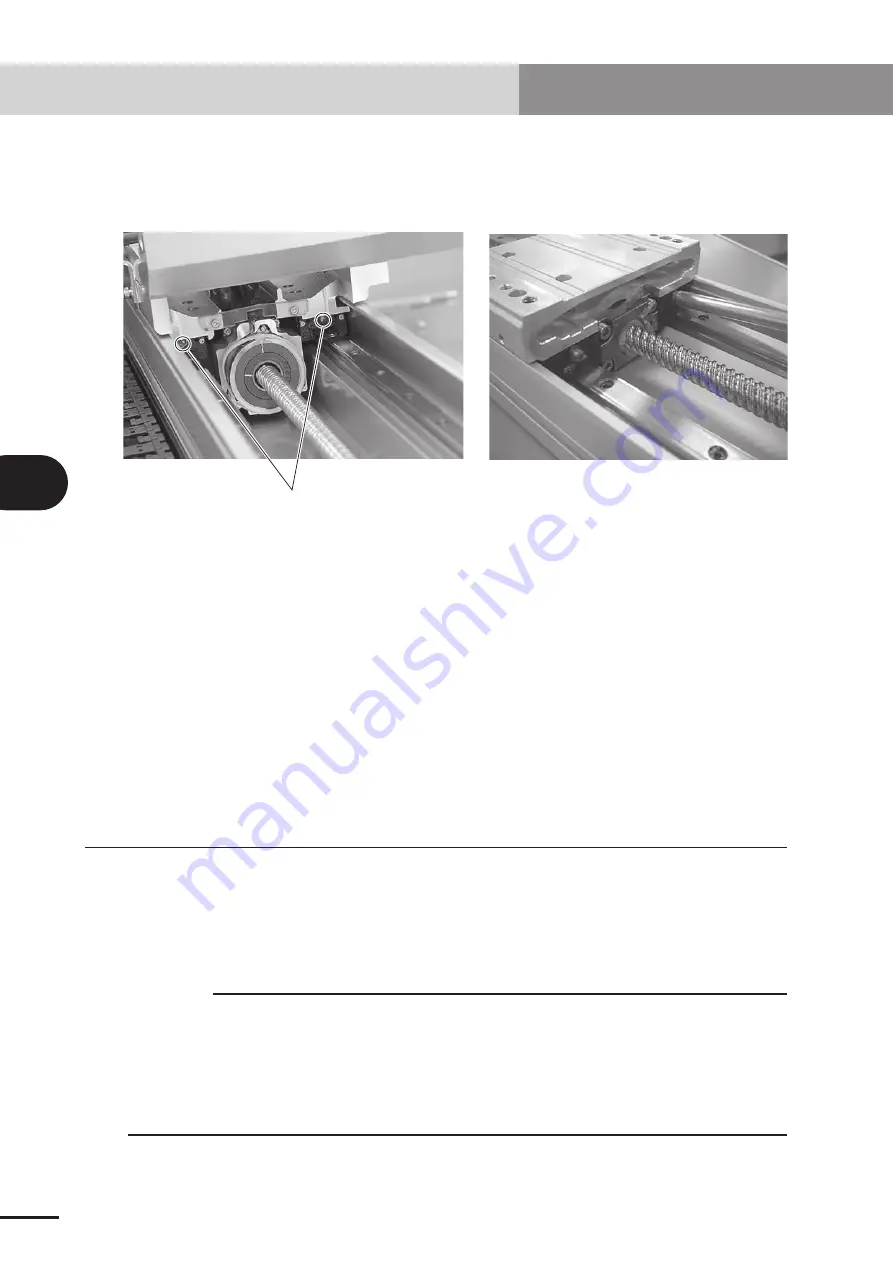

4) Using a grease gun, replenish grease from the grease nipple installed on the linear

guide bearings. Sufficient grease has been replenished when new grease starts to

seep out from the clearance between the linear guide bearings and rail.

Grease nipple

<X-axis>

<Y-axis>

X-axis, Y-axis

The X-axis and Y-axis each have four linear guide bearings. Replenish grease to all

four bearings.

Wipe off any excessive grease that has seeped out to the rail.

Z-axis (ZFL)

Two linear guide bearings are attached. A grease nipple is attached to the counter-

motor side of the slider, so move the slider to the motor side and then start the work.

5) Install the stroke cover.

6) Confirm the surrounding safety, and then turn the controller power ON.

4. Replenishing grease to the ball screw

The X-axis, Y-axis and Z-axis use a ball screw. Grease must be replenished to this ball

screw periodically.

Recommended grease

:

Alvania No. 2 (Showa Shell)

Daphne

Eponex

No.

2

(Idemitsu)

c

CAUTION

• When designated by YAMAHA and the user, special grease, such as splatter-

proof grease, may be applied when the robot is delivered. In this case, apply

the appropriate grease as indicated in the delivery specifi cation drawings, etc.

• Always remove the grease nipple after completing the work. Damage or

positional deviation could occur if the robot is operated with the grease nipple

installed.

4. Replenishing grease to the ball screw

Summary of Contents for NXY

Page 2: ......

Page 6: ......

Page 22: ......

Page 26: ...2 4 MEMO ...

Page 28: ......

Page 32: ...3 4 MEMO ...

Page 34: ......

Page 38: ...4 4 MEMO ...

Page 40: ......

Page 48: ......