6-4

Chapter

6

PERIODIC INSPECTIONS

2-3 Six-month

inspection

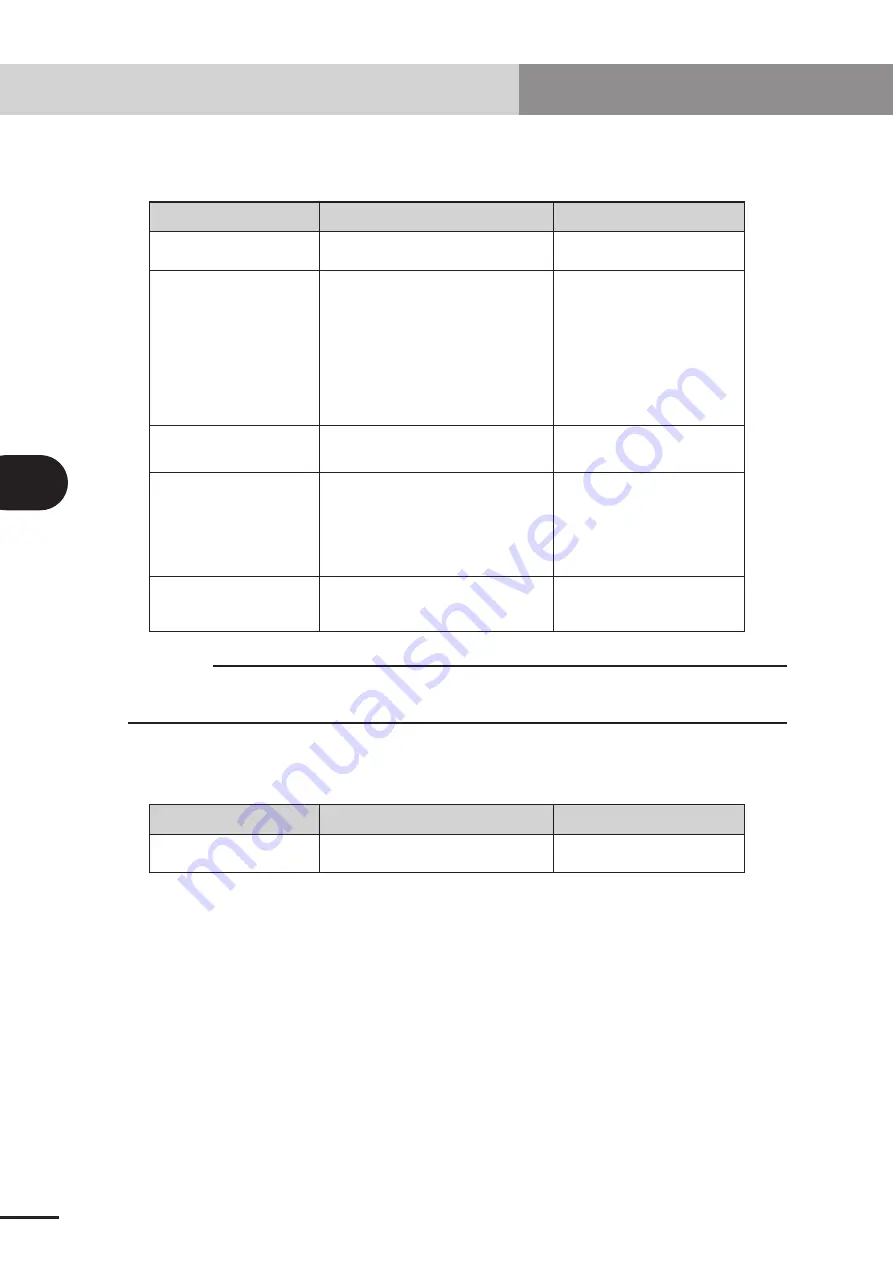

Check the following points every 6 months and adjust or replace parts if needed.

Checkpoints

Check items

Notes

Major bolts and screws

on robot

Check for looseness. Tighten if

loose.

Ball screw, linear guide

• Check the ball screw and linear

guide for backlash. Tighten if

necessary.

• Check for vibration during

operation. Tighten bolts if

necessary to secure drive unit

and/or shaft.

• Check for backlash due to wear.

Consult us if problem

cannot be solved or there

is backlash due to wear.

Controller

• Check if terminals are loose.

• Check if connectors are loose

Greasing to ball screw/

nut section and linear

guide

Apply grease every 6 months to

ball screw/nut and linear guide.

Recommended grease

Albania No. 2 (Shell)

Daphne Eponex No. 2

(Idemitsu)

See "4-3" in this chapter.

Slider

On long-stroke robots, check the

slider inside the top cover for

wear or damage every 6 months.

c

CAUTION

Using grease other than those recommended by YAMAHA might shorten the

service life of the ball screw and linear guide.

2-4 Three-year

inspection

Check the following points every 3 years or more often if the robot is used frequently.

Checkpoints

Check items

Notes

Ball screw/nut section

and linear guide

Check ball screw/nut and linear

guide for backlash due to wear.

Consult us if abnormal

condition is found.

2. Periodic inspection

Summary of Contents for NXY

Page 2: ......

Page 6: ......

Page 22: ......

Page 26: ...2 4 MEMO ...

Page 28: ......

Page 32: ...3 4 MEMO ...

Page 34: ......

Page 38: ...4 4 MEMO ...

Page 40: ......

Page 48: ......