2

3. Preparations before Operation

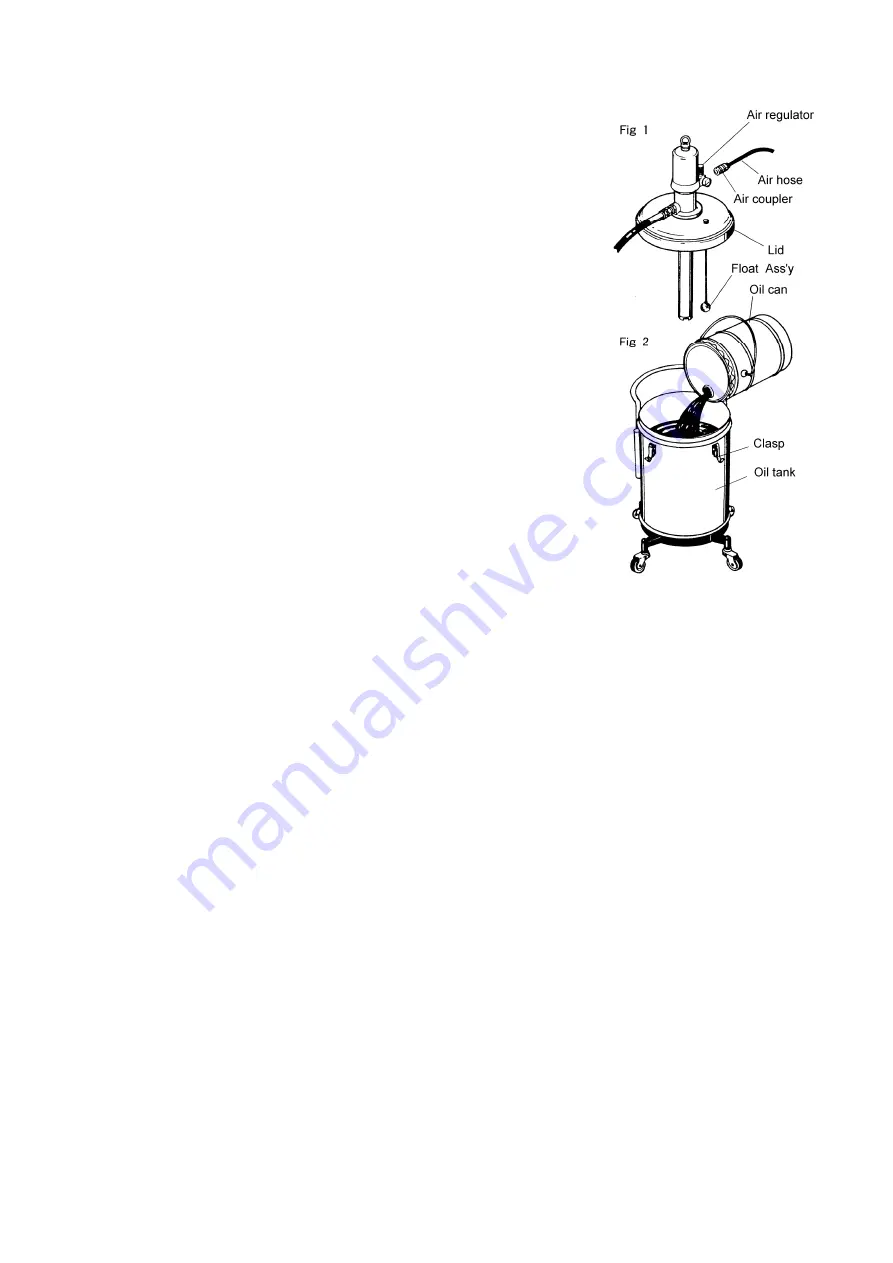

3.1 Setting the Hose

1) Install the attached oil-proof hose and the grip meter at the oil discharge

port of the pump, and clamp the connecting portion securely.

2) Connect the attached air chuck to the air hose and fix it with a hose band.

(The air hose is separately available.) If the air chuck to be connected to

the compressor is not available, purchase it separately. (Fig. 1)

3.2 Setting Oil

1) Release the 3 clasps on the top of the oil tank, and the lid can be removed

together with the pump Assy.

2) Supply new oil in the oil tank. (Fig. 2)

<NOTE>

Take extreme care not to allow sand and dust to adhere on the suction

tube and float of the pump.

3) Put the lid on the oil tank as it was and fix the oil tank and the lid with the 3

clasps.

3.3 Operating the equipment

1) Turn the knob of the air regulator counterclockwise to reset the indicator of the pressure gauge to “0”. After that,

connect the air chuck to supply air.

<NOTE>

Using an air regulator permits adjusting the supply air pressure to the pump and reducing unnecessary pump

motion, thereby improving the work efficiency and extending the life of the pump.

When the knob of the air regulator is turned clockwise, the air pressure will be increased (the indicator of the

pressure gauge gradually goes from “0” to a larger number). When the knob is turned counterclockwise, the air

pressure will be reduced (the indicator of the pressure gauge goes back to “0”).

2) As the knob of the air regulator is gradually turned clockwise, the will be started when the supply pressure is 0.2 or

0.3 MPa.

3) The pump is operated for a while and then stops when the hose is filled with oil. If the gun lever is pulled in this

status, the oil lubricator can be used any time.

4) Set the supply air pressure to 0.5 to 0.7 MPa.

Summary of Contents for SGR-110A5

Page 2: ......