27

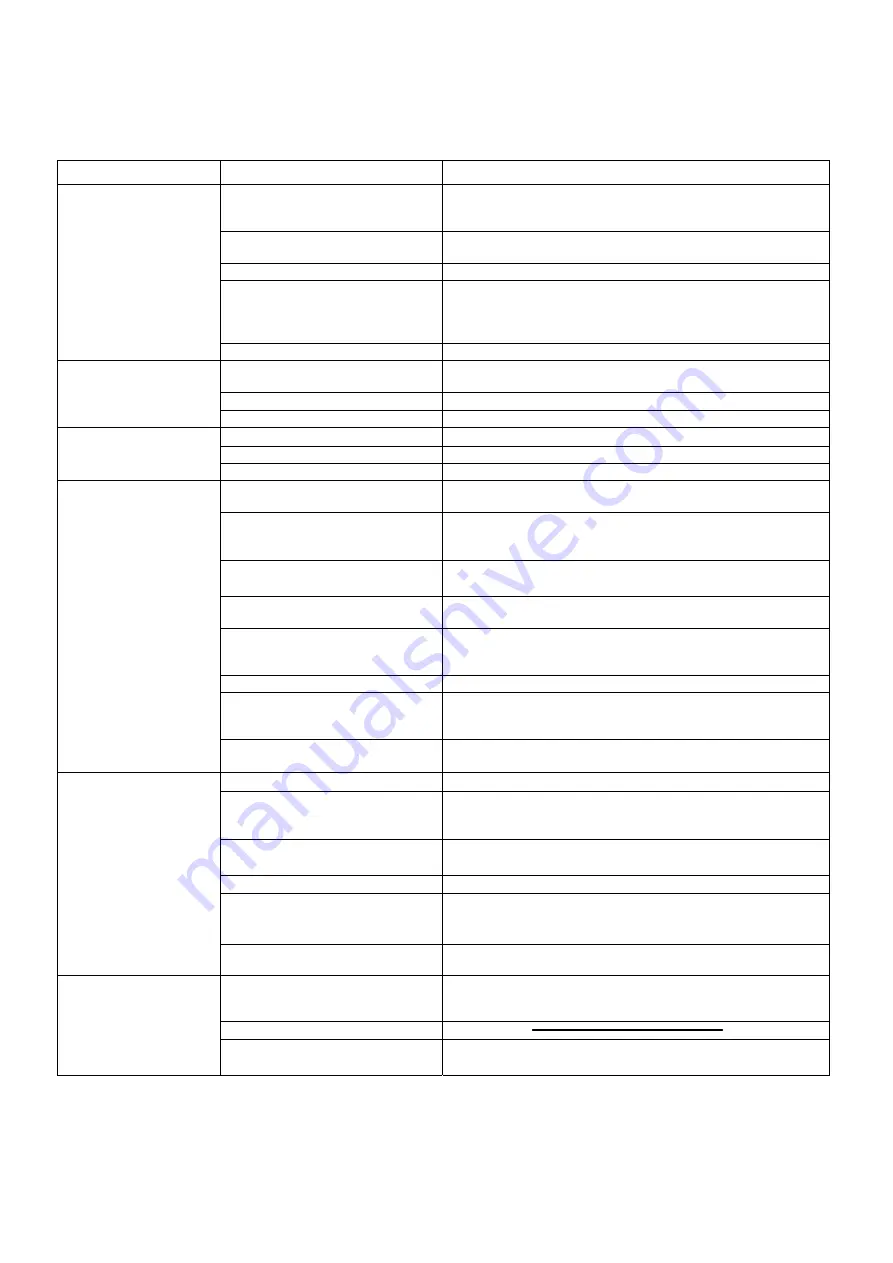

4-3 Troubleshooting

Error condition

Cause

Corrective action

1. The plug of the power cable is

not connected to the AC

outlet correctly.

Connect the plug of the power cable to the AC outlet securely

(AC220 V)

2. AC 220V power is not supplied

to the power supply.

Check the power supply.

(

AC220V

)

3. The fuse blows out.

Replace the blown fuse with a new one (250V

3 A).

4. The plug of the power cable was

disconnected from the AC outlet

during the previous

oil replacement.

To continue the operation, press the START key to restart it.

To abort the operation, hold down the CANCEL key for two

seconds.

The machine cannot be

turned on or you cannot

operate the machine.

5. The control unit malfunctions.

Contact our sales office

1. The speaker or buzzer is not set

to output any sound.

Change the setting.

2.

The speaker/buzzer malfunctions.

Contact our sales office.

The speaker or

buzzer does not output

any sound.

3. The control unit malfunctions.

Contact our sales office.

1.

The signal light is not set to light.

Change the setting.

2. The lamp is burnt out.

Replace the lamp with a new one (AC 100 V, 15 W).

The signal light does not

light.

3. The control unit malfunctions.

Contact our sales office.

1. The filter for the wasted oil is

clogged.

Clean the filter.

2. Since the oil temperature is

low and its viscosity is high, the

flow rate is low.

Start the engine of the car, and idle it for five to ten minutes to

raise the oil temperature sufficiently (50 to 80°C)

3. Oil leaks.

Air gets mixed in with oil.

The filter cap is not attached correctly.

Contact our sales office.

4.

The flexible nozzle is not inserted

sufficiently.

Insert the flexible nozzle into the bottom of the oil pan

securely.

5. The coupler is not attached onto

the wasted oil hose (twin-hose,

black) correctly.

Attach the coupler onto the wasted oil hose (twin-hose, black)

securely.

6. The wasted oil tank is full.

Remove the wasted oil.

7. The upper limit sensor of the

wasted tank is not connected to

the connector correctly.

Connect the upper limit sensor to the connector correctly.

The machine removes

the wasted oil too slowly

or does not remove the

wasted oil at all.

8.

The pump, electromagnetic valve

or control unit malfunctions.

Contact our sales office.

1. The filter for new oil is clogged.

Clean the filter.

2. Since the oil temperature is low

and its viscosity is high, the flow

rate is low.

Raise the oil temperature.

3. Oil leaks.

Air gets mixed in with oil.

The filter cap is not attached correctly.

Contact our sales office.

4. The new oil pail is empty.

Replace the new oil pail with a new one.

5. The coupler is not attached onto

the new oil hose (twin-hose,

red) correctly.

Attach the coupler onto the new oil hose (twin-hose, red)

securely.

The machine supplies

new oil too slowly, or

does not supply any new

oil.

6.

The pump, electromagnetic valve

or control unit malfunctions.

Contact our sales office.

1.

The nozzle for removing the oil is

not attached onto the wasted oil

hose (twin-hose, black) correctly.

Attach the nozzle for exhausting the oil onto the wasted oil

hose (twin-hose, black) securely.

2. The wasted oil tank is empty.

The machine exhausts

the wasted oil too slowly

or does not exhaust the

wasted oil at all.

3.

The pump, electromagnetic valve

or control unit malfunctions.

Contact our sales office.