8.8 MAINTENANCE OF MOTOR

Motor

Under normal conditions the motor is practically maintenance-

free.

Spring activated disc brake

Service to the motor brake is reduced to checking and

adjustment of the nominal brake air gap. The disc brake air gap

should be between 0.15 and 0.6mm (see Tab. 5). This

guarantees short reaction time and low noise emission. When

the wear of the brake lining comes down to the point where the

maximum possible air gap has finally been reached, the brake

lining has to be replaced.

Attention:

Do not allow the brake friction pads to come into

contact with lubricant or similar contaminants.

The table below shows the dimensions of the brake air gap that

have to be maintained:

Attention:

When checking the air gap, the motor must be

switched off and the hoist must be unloaded.

• Measure air gap SLu between armature disc and magnet

part with feeler gauge.

• Compare measured air gap value with max. admissible air

gap SLu (see Tab. 5).

• If necessary, replace rotor with brake lining.

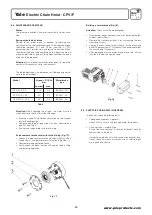

Replacement of brake rotor with friction lining (Fig. 17):

• Loosen the three countersunk socket screws (item 3), lift-off

flange (item 2) and replace rotor with friction lining (item 1).

• Reassemble in opposite sequence.

• Finally, check the brake function with nominal load in lifting

and lowering operation.

Yale

Electric Chain Hoist - CPV/F

®

13

www.yaleproducts.com

Model

Air gap + 0.1 SLu Motor brake

mm type

nominal max.

CPV/F 2-8, 5-4 0.15 0.3 BFK457 - 05

CPV/F 5-8, 10-4 0.2 0.4 BFK457 - 06

CPV/F 10-8, 20-4 0.2 0.6 BFK457 - 08

Tab. 5

Fig. 17

Build-up of motor brake (Fig. 18):

Attention:

The unit must be de-energised!

• Disassemble the control cover (item 2) by loosening the four

cylinder screws (item 1).

• Remove the transformer (item 3) by unscrewing the four

crosshead screws.

• Loosen the four socket screws (item 4) of the brake and

pull-off the brake (item 5). Disconnect the control cable from

the circuit board if necessary.

• After replacement of the motor brake, make sure that the

function is tested with nominal load.

Fig. 18

8.9 ELECTRIC CHAIN HOIST IN GENERAL

In particular, check the following parts:

• Threaded connections in general.

Check all nuts, screws and locking devices for tightness.

• Chain container - material type.

Ensure the chain container is securely fastened. Check for

tears or wear in the fabric.

Connection between hoist and suspension bracket resp.

trolley. Check for cracks or wear. Ensure all safety devices

are in place and secure.

Yale

CPV/F

®