15

When loading the filament, the material used for presetting the printer will be located at

the center position of the nut in the feed module. You may adjust the gear tightness

according to the clamping force indicated in the following filament characteristics.

During the printing process, you may also execute fine-tuning of the gear for the feed

module in order to achieve the desired tightness.

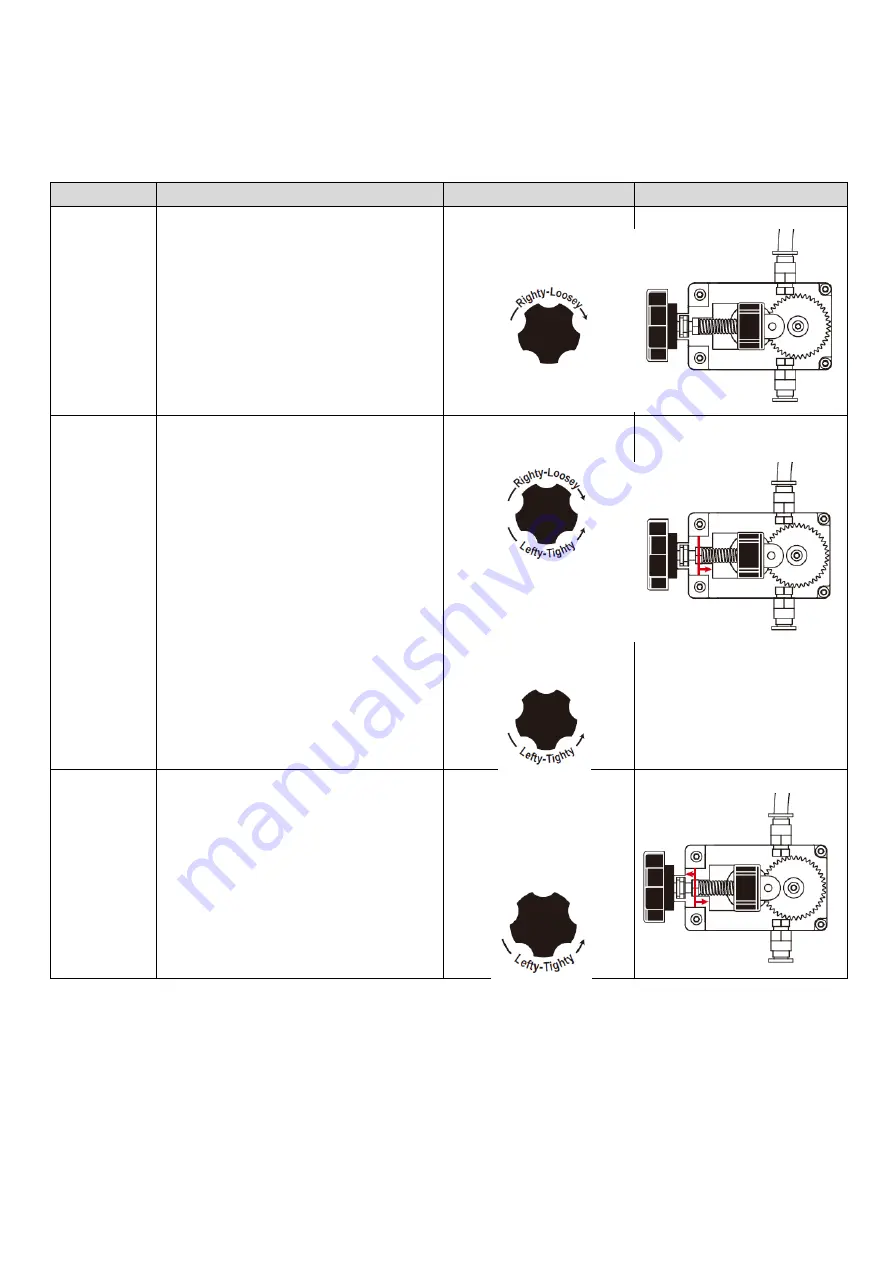

Material

Observe the feeding condition

Adjustment Methods

Hex nut position

Soft material

Observe whether the filament inside the

guide tube is excessively squeezed,

twisted, or unsmooth feeding conditions,

and whether the flow of filament is stable.

If the filament is presenting any

squeezing, warping or unsmooth feeding

sign, please adjust the clamping force of

the gear in order that the filament will be

extruded steadily from the print head.

Clockwise to loosen

Middle left

General

When it is impossible to judge the

material characteristics or when using

general materials, it is recommended to

adjust the nut to the center position first,

and observe whether the filament feeding

condition inside the guide tube is stable.

If the flow of the filament is not smooth,

please adjust the gear clamping force.

Adjust the net to the

center position

If the filament cannot be

extruded, turn the nut

leftward until tight (adjust

in a counterclockwise

direction)

Center or middle right

Hard material Observe whether the filament flows out

stably and smoothly, or whether there are

mechanical abnormal noises during the

process.

If the filament cannot be

extruded, turn the nut

leftward until tight (adjust

in a counterclockwise

direction)

Middle left or middle right