8

Setting

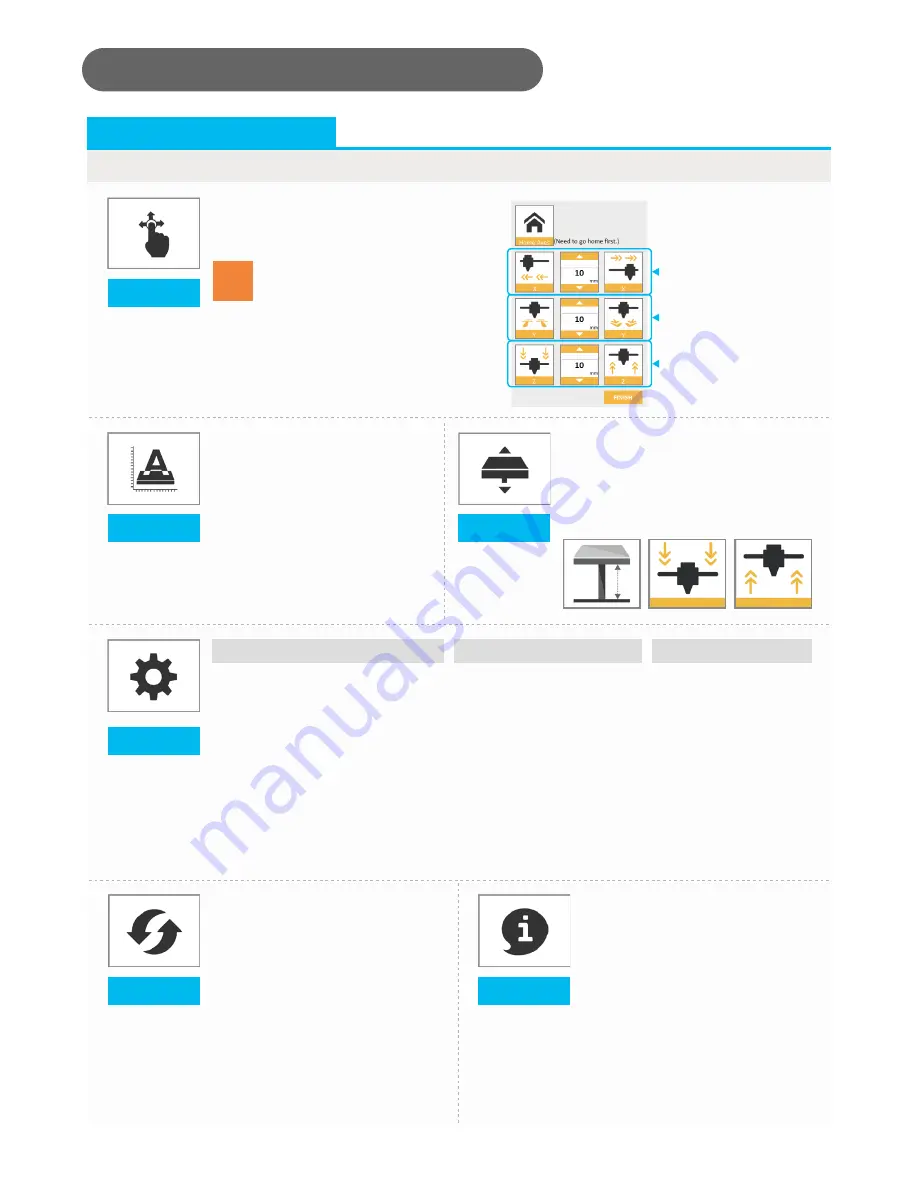

Interface Introduction

Please follow the on-screen

instructions.

Print bed calibration may be

implemented before the printing

process.

Move the extruder module to the

lower left corner of the printing

area. Please refer to the calibrate

instructions provided by the

software.

Z-Offset function will help you to

adjust the printing distance between

the print bed and extruder module.

Each adjustment has a step of 0.05

mm.

Manually adjust the movement of X/Y/Z

Axis for printer maintenance.

Jog Mode

Calibrate

Z-Offset

Move extruder module

rightwards and leftwards.

Move extruder module

forwards and backwards.

Move the print axis (Z-AXIS)

upwards and downwards.

Software Functional Descriptions

Others

Automatic horizontal calibration

Restore Default

Buzzer

Info

FW upgrade

Automatic horizontal calibration

may either be ON or OFF.

Default: ON.

The software would automatically

implement horizontal calibration

and compensation accordingly.

Printing speed will be improved if

automatic horizontal calibration

has been switched to OFF.

However, this may affect printing

quality.

Buzzer may either be ON

or OFF. Default: ON.

When the buzzer is

turned on, the printer will

output an audible signal

when a button is pressed,

receiving data, print job

is finished, or issue is

detected.

Click

Restore Default

to reset to default

setting.

Please upgrade the latest

firmware version for the best

printing quality of the printer.

Information related to printer

setting.

Note

1. First click on

Home Axes

.

The extruder module will be

returned to the initial axis

position.

2. You may manually enter

the adjustment value:

Range: 1 to 150; step: 1 mm