2

Indicator signals

Status

Action

Solid green

Standby/Ready to print

-

Flashing green

Receiving data

-

Solid red

General error

Press the button to return to printing status, refer

to instructions in software to fix. *

Flashing red

Critical error

Refer to instructions in the software to solve the

issue or reboot the Nano. *

Solid orange

Printing

-

Pause the print

To pause the print, press the button once.

Cancel the print

To cancel the print, press and hold the button for

5 seconds.

Flashing orange

Paused

-

Resume the print

To resume the print, press the button once.

Pulsing orange

Job complete (printing complete /

printing cancellation complete)

To return to stand-by mode, press the button

once.

8

9

12

13

14

1

3

5

2

6

4

7

11

10

Print Technology

Fuse Filament Fabrication (FFF)

Weight

4.5kg

Dimensions

378*280*355 mm

Print Dimension

120*120*120 mm

Print Resolution

0.1-0.4 mm

Nozzle Diameter

0.4 mm

Print Material

PLA

Filament Diameter

1.75 mm

Print Software

XYZmaker

File Format

.3w/ .stl/ .3mf

Operating System

Microsoft Windows 7 +

Mac OSX 10.9 +

Connectivity

USB cord 2.0

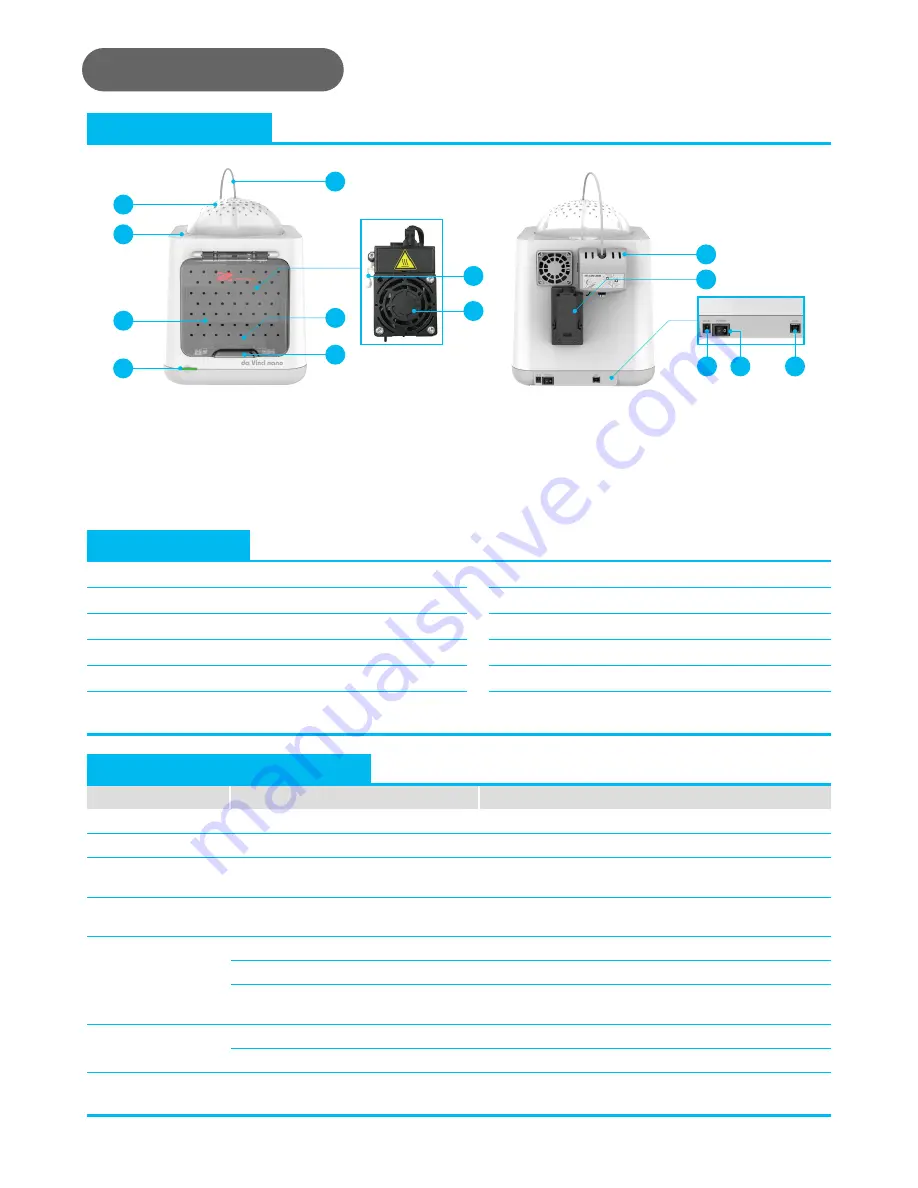

1. Top cover

5. Guide tube

9. Front cover handle

13. Power switch

2. Top cover latch

6. Detection head trigger

10. Feed module

14. USB port

3. Print bed

7. Extruder module

11. Filament holder

4. Function button/

Status indicator

8. Hold-open component

12. Power socket

Product Details

Specification

Button and Indicator light

Product Overview

*Please refer to "XYZmaker" software screen to solve the problem.