April

2016

P 5

HD23F1JW0D5

da Vinci

Jr.1.0

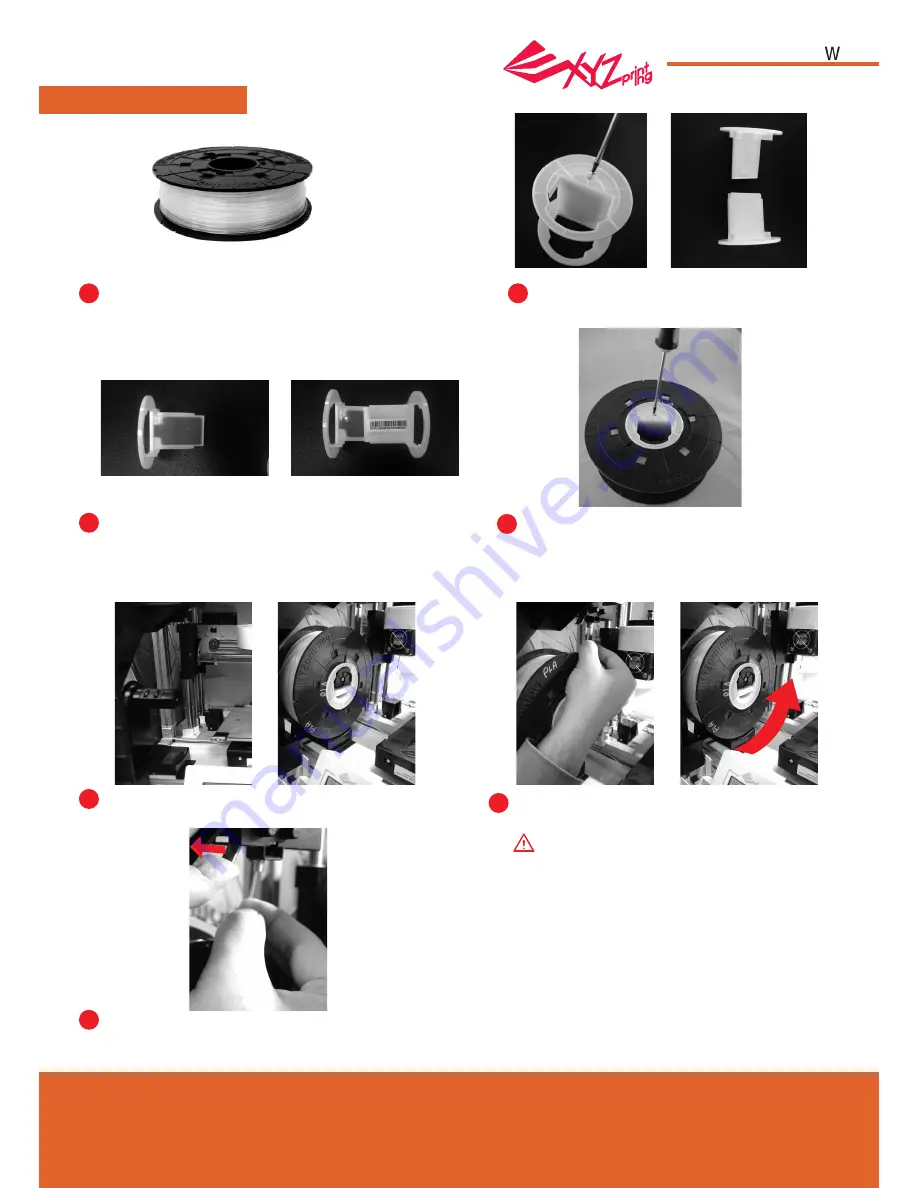

First retrieve filament spool to install the filament

spool axle ring.

Place the assembled filament spool (with the spool axle

rings) on the filament holder on the left side of the printer.

Pull out a section of the filament and insert it into

the feed port.

Caution: Pay attention to the direction the

filament is being pulled out and ensure that

the filament spool axle is being rotated in the

correct manner.

Open the release arm and push the filament all the way

to the bottom so that the front end of the filament is

completely inserted into the feed module.

Take out and separate the filament spool axle

ring into its two components.

Install the sensor chip. Please pay special attention to

the position of the installation holes on the chip.

Insert the filament spool axle ring components

to either side of the filament spool, and use a

cruciform screwdriver to tighten and secure the

rings to the axle to complete the installation of

the filament spool axle rings.

1

2

3

4

5

6

7

Load Filament

CHANGE SPOOL