14

15

Next, use the up or down arrow keys to adjust the shut off time from 0

to 60 minutes. Press enter to save the new shutoff time. Next, highlight

the ESC-Exit box and press enter to close the submenu.

To disable Auto Shutoff, set the Time in Minutes to 0 (zero).

cell constant

The Cell Constant displays the cell constant of the conductivity cell.

The cell constant is calculated and updated each time a conductivity

calibration is performed. The cell constant range is 4.0 to 6.0. Resetting

the System Menu resets the cell constant to 5.0.

resettIng the systeM setUp MenU and

cell constant to factory defaUlt

To reset the Pro1030 settings and conductivity cell constant back to

factory default, press the down arrow key while in the System Setup

menu until the Reset - box is highlighted, then press enter. The

instrument will prompt you to confirm the reset. Highlight Yes and

press enter to continue with the reset or highlight No and press enter

to cancel the reset. A Factory Reset will not affect data saved in the

instrument’s memory.

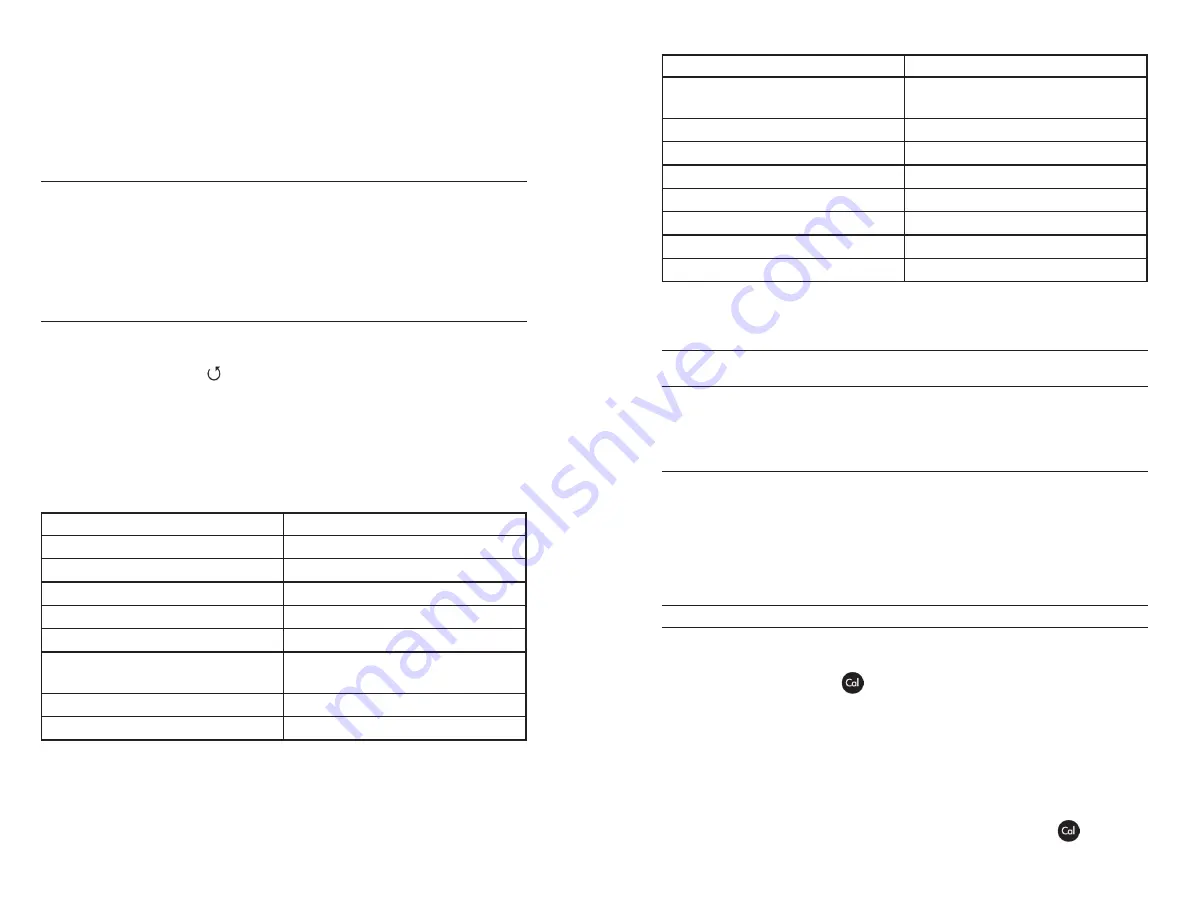

The following will be set in the Pro1030 after performing a reset:

Parameter

Reset Defaults

Audio

on

Contrast

Set to mid range

Temperature Units

°C

ISE Sensor Type

pH

ISE Units

pH

ISE Auto Stable

off (0.0 % Change

and 10 seconds)

pH Buffer Set

USA

Conductivity Units

cond mS/cm and spc mS/cm

Parameter

Reset Defaults

Conductivity Auto Stable

off (0.0 % Change

and 10 seconds)

SPC Reference Temperature

25°C

SPC Temperature Coefficient

1.91%/°C

TDS Constant

0.65

Language

English

Auto Shutoff

30 minutes

Conductivity Cell Constant

5.0

pH Calibration

Factory default

C A L I B R A T I o N

teMperatUre

All Pro1030 cables have built-in temperature sensors. Temperature

calibration is not required nor is it available.

ph calIBratIon

The Pro1030 pH sensor can be calibrated by performing a 1, 2 or 3-point

calibration. At least one of the calibration points must be done with

pH buffer 7 or 6.86. For auto buffer recognition to work properly with

an older or dirty sensor, calibrate in buffer 7 or 6.86 first. For highest

accuracy, use fresh, traceable pH buffers and ensure the sensor and

calibration vessel are clean.

1-PoINT CALIBRATIoN

1. Place the sensor in pH buffer 7 or 6.86 and allow the temperature

and pH readings to stabilize.

2. Press and hold Cal

for three seconds.

3. Highlight pH and press enter. If pH is not listed as an option,

check the System Setup menu to ensure pH is enabled in the

ISE Sensor Type menu.

4. Highlight 1 point and press enter.

5. If necessary, use the up and down arrow keys to adjust the pH

buffer value. Note the pH mV reading which ideally should be

between -50 and +50 in buffer 7.

6. Press enter to complete the calibration or press Cal

to cancel.