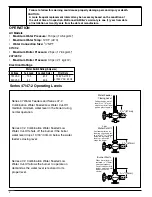

STEP 4 - Installing Series 247/247-2 Water Feeder to Boiler

Burner

Boiler

City Water Supply

Return

Header

Series 247

Water

Feeder

Casting

Line

ByPass

Valve

Pipe the Series 247/247-2 water feeder so that

the line on the casting is 3" (76mm) above the

minimum safe operating level as specified by

the boiler manufacturer.

Recommended Piping

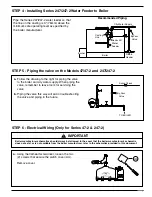

STEP 5 - Piping the valve on the Models 47/47-2 and 247/247-2

TO BOILER

By-Pass

Valve

Swing Check

STEP 6 - Electrical Wiring (Only for Series 47-2 & 247-2)

AA

a.

Using the flathead screwdriver, loosen the two

(2) screws that secure the switch cover (AA).

Remove cover.

7

!

IMPORTANT

Boiler manufacturer schematics should always be followed. In the event that the boiler manufacturer's schematic

does not exist, or is not available from the boiler manufacturer, refer to the schematics provided in this document.

a.

Follow the drawing to the right for piping the valve

to the boiler and city water supply. When piping the

valve, remember to leave room for servicing the

valve.

b.

Piping the valve this way will aid in troubleshooting

the valve and piping in the future.