11

MAINTENANCE

SCHEDULE:

Weekly

• Blow down when boiler is in operation.

Annually

• Disassemble and inspect/clean strainer screen.

Replace if screen is torn or not able to be cleaned.

• Remove and inspect/clean cartridge.

Replace if

poppet does not move freely or debris cannot be

removed.

• Remove lower float chamber and inspect internal

parts.

Clean out all mud, silt, sediment and debris from

chamber, float mechanism and other waterside

components.

• Inspect equalizing piping.

Clean or replace as

required.

• Check all wires for brittle or worn insulation.

• Check for leaks at gasket surfaces and solder joints.

Replace entire unit including equalizing piping every

10 years.

More frequent cleaning or replacement may be

required if used in locations where water treatment is

required or in applications with high make-up water

requirements.

NOTE

Use clean water to rinse components and surfaces. DO

NOT use sharp objects to scrape off any accumulations

of sediment or debris.

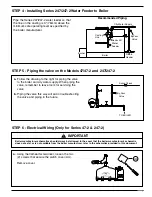

Unit is making noise.

a)

Cause:

Under certain system conditions, there may be

a vibration when the valve mechanism (cartridge poppet)

is slightly open.

Solution:

Install a pressure reducing valve, such as the

Bell & Gossett B-38, in the inlet water line before the

feeder valve.

Burner switch not working.

a)

Cause:

Cam worn or broken.

Solution:

Replace cam assembly (CO-106/302900).

b)

Cause:

Linkages not transferring float movement

to switch.

Solution:

• Linkage pins may be worn or broken which would

require purchasing a new valve assembly

(SA47-101-102/341600).

• Float may be damaged, sediment may have

accumulated in chamber or equalizing piping may be

plugged. Perform testing to determine what the

problem may be and correct.

Water leaking from bellows

a)

Cause:

Continuous exposure to chemicals or water with

pH higher than 9.0 can cause the solder to deteriorate.

Solution:

Remove source of chemicals or consider

replacing control with one that is suitable for the

application.

TROUBLESHOOTING (cont'd)