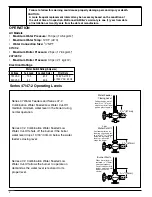

F

G

g.

Slide the black "Y" (F) casting over the nipple (G)

in accordance with Step 2d, but do not tighten.

L

F

M

N

L

P

U

U

K

Q

Q

h.

1). Apply sealant to the external threads of the nipple (L)

of the upper "Y" connection. Using a pipe wrench,

tighten the nipple (L) into the 1/2" (15 mm) NPT

tapping (M) of the black "Y" casting (F). Slide union

nut (U) over nipple (L). Using a pipe wrench tighten

the upper “Y” connection (N) to nipple (L). Tighten to

54 ft

•

lb (74 N

•

m).

2). Apply sealant to the external threads of the tailpiece (P)

of the lower "Y" connection. Slide union nut (U) over

tailpiece (P). Using a pipe wrench, tighten the tailpiece

(P) into the 1/2” (15 mm) NPT tapping (Q) in the lower

half of body (K). Tighten to 54 ft

•

lb (74 N

•

m).

5

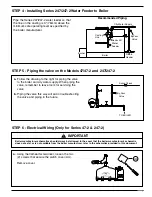

J

H

K

e.

Remove the plug (H) from the 1/2" (15 mm) NPT

tapping (J) in the top of the feeder body (K).

J

G

K

No Threads

f.

Apply thread sealant to the external threads. Using

a pipe wrench, tighten the 1/2" (15 mm) NPT nipple

(G) into the tapping (J) on the top of the feeder (K)

to approximately 54 ft

•

lb (74 N

•

m).

Note:

Nipple (G) is only threaded on one end.

Upper “Y”

Lower “Y”

When using pipe or tape sealant on the external threads of pipes or fittings, follow the manufacturers

instructions. Use sparingly and do not place on the first thread.

!

IMPORTANT