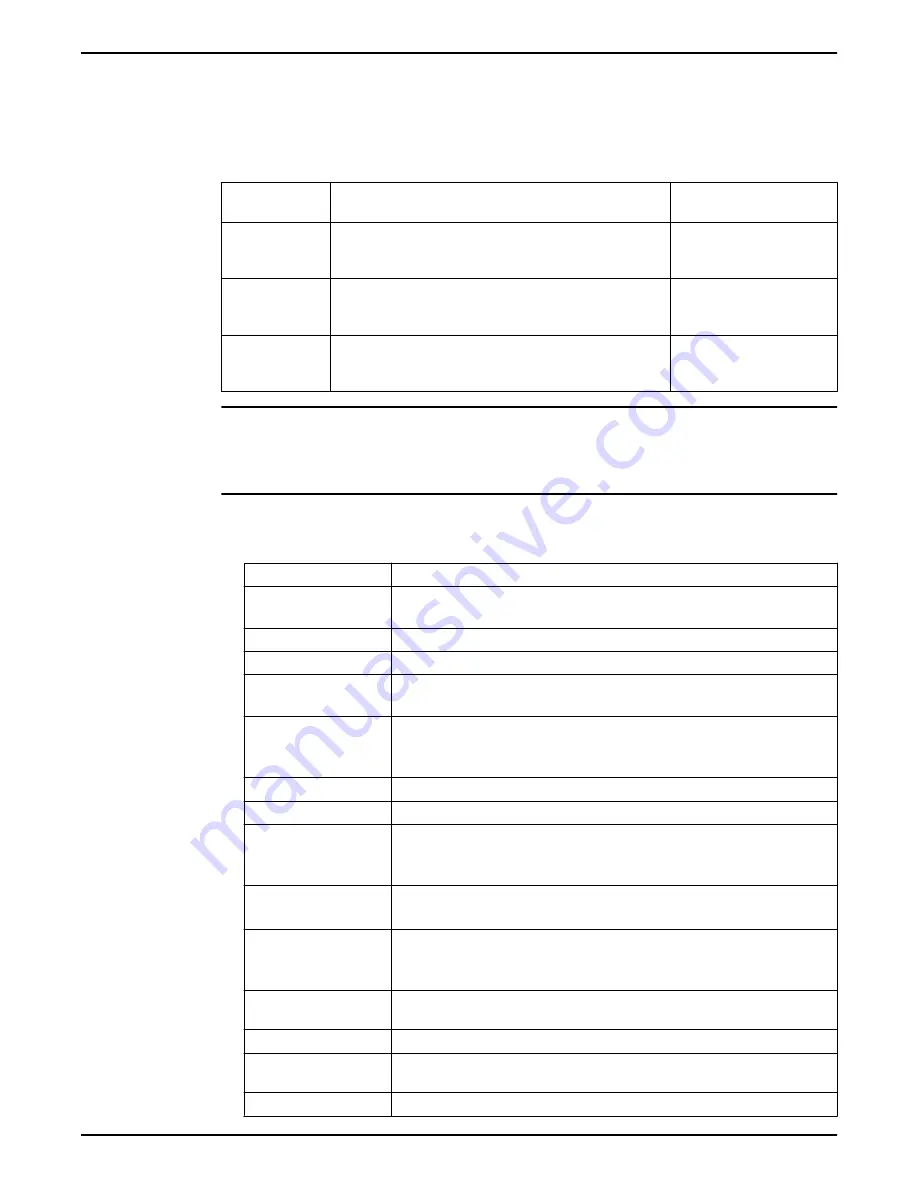

Hexagon screws with countersunk heads

For hexagon socket head screws with countersunk head, maximum torque for all property

classes must be 80% of the values for property class 8.8 above.

7.2 Maintenance intervals

Type of

maintenance

Purpose

Inspection interval

Initial inspection

A Xylem-authorized personnel checks the pump condition.

From the results, the personnel recommends the intervals for

the periodical inspection and overhaul for the installation.

Within the first year of

operation.

Periodical

inspection

The inspection prevents operational interruptions and machine

breakdowns. The measures to increase performance and pump

efficiency are decided for each application.

Up to 12,000 hours or three

years, whichever comes first.

Overhaul

The overhaul lengthens the operating lifetime of the product. It

includes the replacement of key components and the measures

that are taken during an inspection.

Up to 24,000 hours or six

years, whichever comes first.

NOTICE:

Shorter intervals may be required when the operating conditions are extreme, for

example with very abrasive or corrosive applications or when the liquid temperatures

exceed 40°C (104°F).

7.2.1 Inspection

The list is valid for initial inspection and periodical inspection.

Service item

Action

Cable

1. If the outer jacket is damaged, replace the cable.

2. Check that the cables do not have any sharp bends and are not pinched.

Electrical connections

Check that the connections are properly secured.

Electrical cabinets

Check that they are clean and dry.

Impeller

1. Check the clearance.

2. If necessary, adjust.

Stator housing

Drain any liquid.

For more information, see

Drain the liquid from the stator housing

page 38.

Level regulators

Check the condition and functionality.

Lifting device

Check that the local safety regulations are followed.

Lifting handle

1. Check the screws.

2. Check the condition of the lifting handle and the chain.

3. If necessary, replace.

Oil

If necessary, fill with new oil.

For more information, see

on page 39.

O-rings

1. Replace the O-rings of the oil plugs.

2. Replace the O-ring of the inspection plug.

3. Lubricate the new O-rings.

Overload protection and

other protections

Check the correct settings.

Personnel safety devices

Check the guard rails, covers, and other protections.

Thermal contacts, for Ex-

approved versions

Normally closed circuit; interval 0–1 ohm.

Voltage and amperage

Check the running values.

7 Maintenance

6020.180/090 Installation, Operation, and Maintenance Manual

37

Summary of Contents for FLYGT Concertor

Page 1: ...Installation Operation and Maintenance Manual 886211_9 0 6020 180 090 Concertor...

Page 2: ......

Page 58: ......

Page 59: ......