Tightening Torque for Temperature Pilots

Temperature Actuator Assembly Testing

1. Loosen calibration set screw on indicator ring. Drop

away from dial.

2. Loosen Allenlock set screw on knob assembly.

Unscrew adjustment knob assembly from actuator.

3. Insert flat ended smooth wooden dowel into the

bellows.

Note: Bellows should be firm. If it is spongy, the

actuator has lost its liquid fill. For more precise testing,

use a depth micrometer. The bellows should move

0.00057 inch (0.0144mm) per degree change of the

sensing bulb.

4. If the actuator does not operate properly, it must be

replaced.

Temperature Actuator Assembly Installation

1. Loosen the calibration ring screw and the adjustment

knob screw.

2. Under normal conditions. Slowly rotate the knob

counterclockwise to increase temperature, or clock-

wise to decrease temperature to achieve the desired

system temperature.

3. Allow system temperature to stabilize at the desired

set-point temperature and normal load conditions.

Securely tighten the adjustment knob set screw.

4. Rotate calibration ring so that the indicator arrow is in

alignment with the desired set-point temperature.

Securely tighten the calibration ring set screw.

Seal Bellows Replacement Assembly

1. Remove actuator assembly. Complete steps 1-2

under "Temperature Actuator Assembly Testing"

above.

2. Turn body assembly over with bottom plug up. The

push rod and overheat assembly will drop out.

3. Place body assembly in vise with adjustment sleeve

turned up.

4. Unthread adjustment sleeve from body.

5. Remove from vise and turn body over with bottom

plug up. The brass washer, bellows assembly and

plug will drop out.

6. Inspect parts and replace as necessary.

7. Reassemble and recalibrate actuator. Complete steps

1-5 under "Temperature Actuator Assembly

Installation" above.

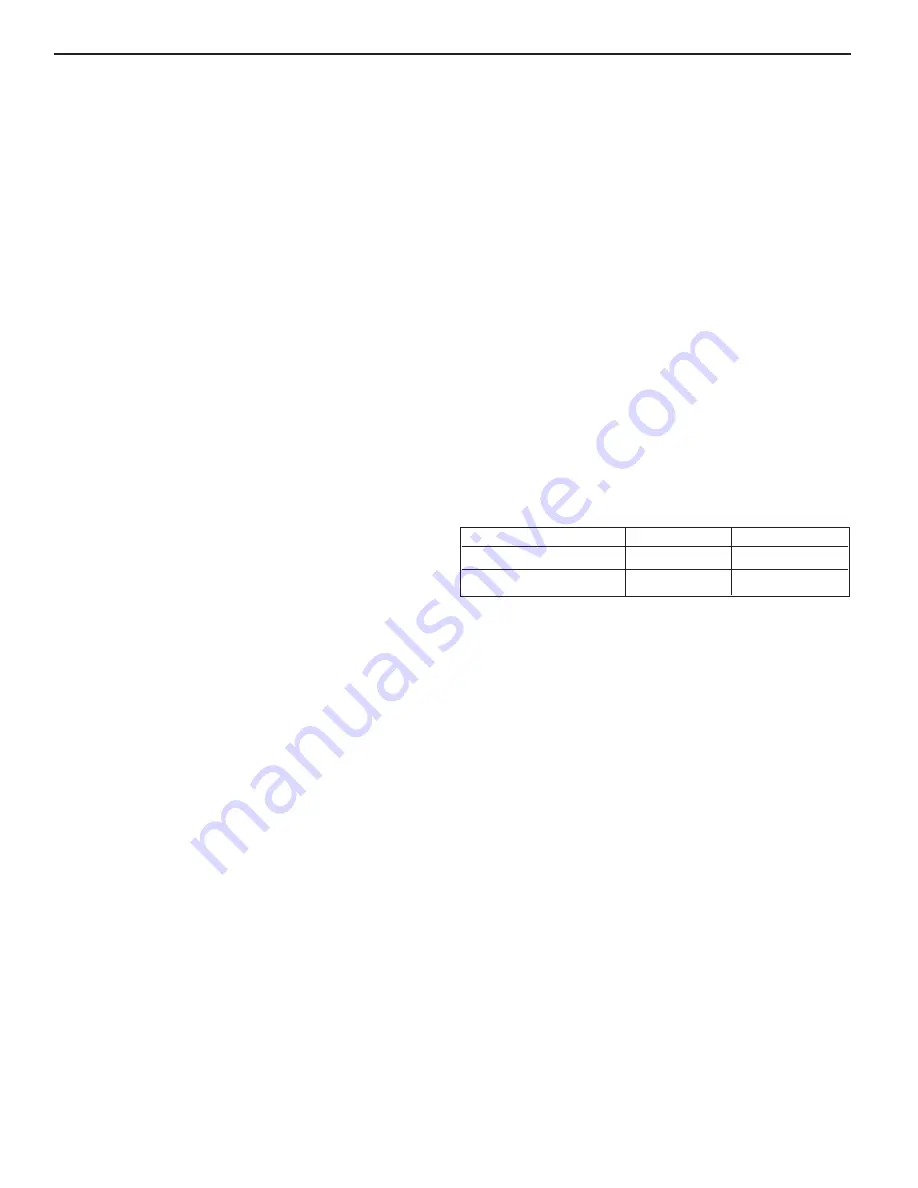

lbf-ft

N-m

Bottom Cap

80 – 90

108 – 122

Brass Sleve to Body

80 – 90

108 – 122

22