Series 8100/8150/8200/9100 Fire Pump

19

AC6102 Rev 0

5

7.5.2.1 Angular Alignment

To check angular alignment, mount dial indicator (A) to the

coupling half (X), and position the dial indicators button on the

face of the opposite coupling half (Y). Scribe index lines on

both coupling hubs as shown in Fig. 10. Set the dial to zero,

rotate both coupling halves together, so that the index lines

match; ensuring that the indicator button always indicates off

the same spot. Check the coupling manufacturer’s guidelines

for the acceptable alignment tolerances.

7.5.2.2 Parallel Alignment

To check parallel alignment, mount dial indicator (P) to the

coupling half (X), and position the dial indicators button on the

outside diameter of the opposite coupling half (Y), (see Fig.

10). Set the dial to zero, rotate both coupling halves together,

so that the index lines match; ensuring that the indicator

button always indicates off the same spot. Check the coupling

manufacturer’s guidelines for the acceptable alignment

tolerances.

7.5.3

Alignment of grid couplings

The following procedure is intended for mounting and

alignment of Rexnord Industries, LLC and Clarke Fire

Protection Products, Inc., Type T10 Close Coupled Grid

Couplings.

Alignment is shown using a spacer bar and straight edge,

which has been prove to be accurate for many industrial

applications. However, for superior final alignment, the use of

dial indicators is recommended, per 7.5.2.

7.5.3.1 Mount Seal and Hubs

Clean all metal parts using non-flammable solvent. Coat the

seals lightly with coupling manufacturer supplied grease and

place on shafts before mounting shaft hubs. Install keys and

mount hubs with flange faces flush with the shaft ends.

Reposition hubs on shafts as required achieving the hub gap

specified in table 5. The length of engagement on each shaft

should be approximately equal to the shaft diameter. Tighten

the setscrews.

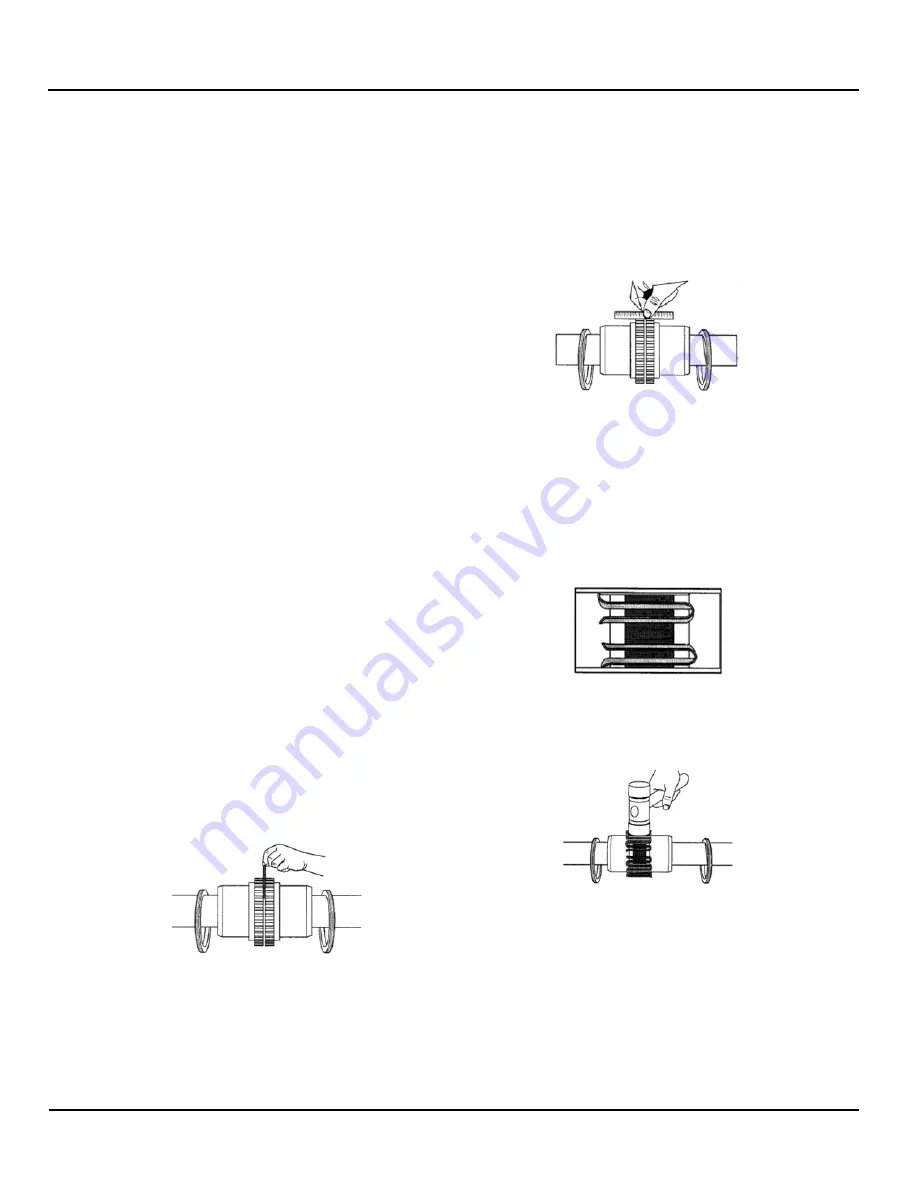

7.5.3.2 Gap and Angular Alignment (X-Y)

Use a spacer bar equal to thickness to the gap specified in

Table 5. Insert bar, as shown above to the same depth at 90°

intervals and measure clearance between the bar and hub

face with feeler gage. The difference in minimum and

maximum measurements must not exceed the angular

installation limits specified in Table 5.

Fig. 11

Using Spacer Bar

7.5.3.3 Parallel Offset Alignment (P)

Align so that a straight edge rests squarely, (or within the

limits specified in Table 5 on both hubs as shown above and

also at 90° intervals, (see Fig. 12). Check with feeler gages.

The clearance must not exceed the Parallel Offset installation

limits specified in Table 5.

If adjustment is needed, loosen the motor bolts and add or

remove an equal amount of shims under each motor foot to

align the height. To correct side misalignment, strike the side

of the motor foot with a mallet.

Tighten the motor bolts and check again. Re-check alignment

in all directions, if a correction is made. Repeat the process

until the desired result is obtained.

Fig. 12

Using Straight edge

7.5.3.4 Insert Grid

Completely pack gap and grooves with coupling manufacturer

supplied grease before inserting grid. When grids are

furnished in two or more segments, install them so that all cut

ends extend in the same direction as shown in Fig. 13. This

will ensure correct grid contact with non-rotating pin in cover

halves.

Fig. 13

Grids magnified

Spread the grid slightly to pass over the coupling teeth and

seat with a soft mallet, (see Fig. 14).

Fig. 14

Seating the grid

7.5.3.5 Pack with grease and assemble covers

Completely pack the spaces between and around the grid

with as much grease as possible and wipe off excess flush

with top of the grid. Position seals on hubs to line up with the

grooves in the cover. Position gaskets on flange of lower

cover half and assemble covers so that the match marks are

on the same side, (see Fig. 15). Secure cover halves with

fasteners tightening to torque specified in Table 5.

Summary of Contents for AC Fire Pump 8100 Series

Page 2: ...Series 8100 8150 8200 9100 Fire Pump 1 AC6102 Rev 05...

Page 4: ...Series 8100 8150 8200 9100 Fire Pump 3 AC6102 Rev 05...

Page 8: ...Series 8100 8150 8200 9100 Fire Pump 7 AC6102 Rev 05...

Page 41: ...AC6102 Rev 05 40 Table 14 Troubleshooting List...

Page 50: ...Series 8100 8150 8200 9100 Fire Pump 49 AC6102 Rev 05 A Appendix...