Loading Paper

Chapter 2: Loading Print Media

❖

2-17

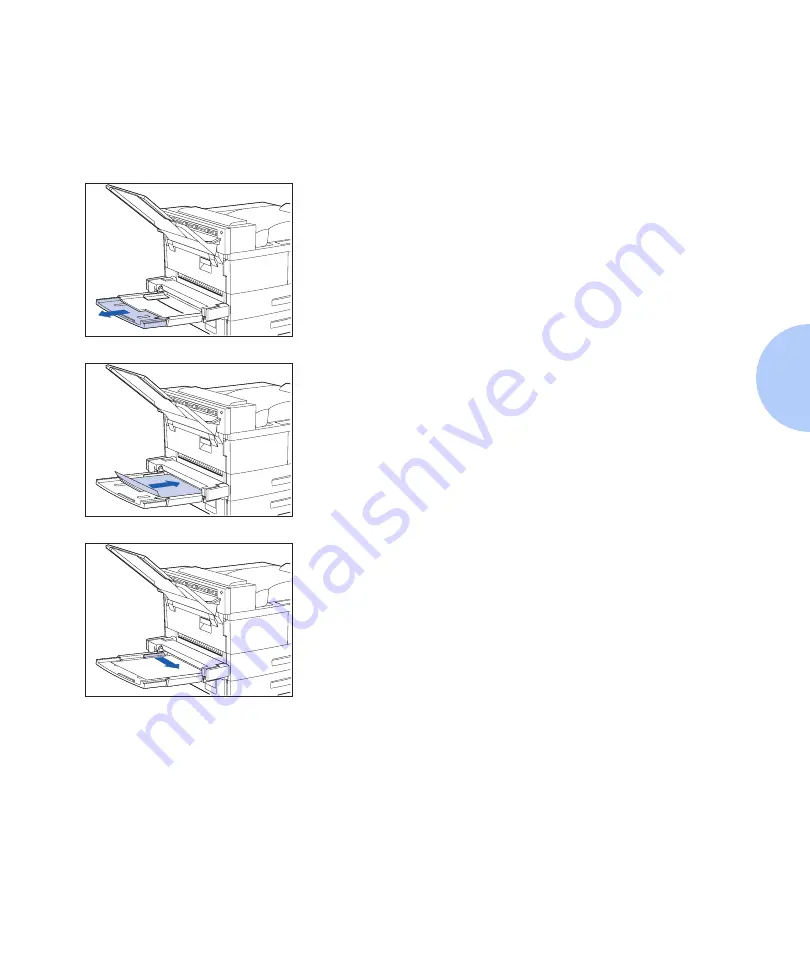

50 Sheet Bypass

Feeder

The 50 Sheet Bypass Feeder holds up to 50 sheets of 20 lb

(80 g/m

2

) paper. Refer to the section

(page 2-2) for acceptable media sizes and weights.

1

If necessary, pull out the extension tray to fit the length of

paper to be used.

2

Place the paper along the right side of the Bypass Feeder

(refer to Figure 2.4 on page 2-19 and Figure 2.5 on

page 2-20 for paper orientation, and to Figure 2.6 on

page 2-21 for envelope orientation).

3

Push the paper guide slightly to touch the paper stack (to

ensure contact with the paper sensor).