INKS

5-6

XEROX DOCUPRINT 4850/4890 IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE

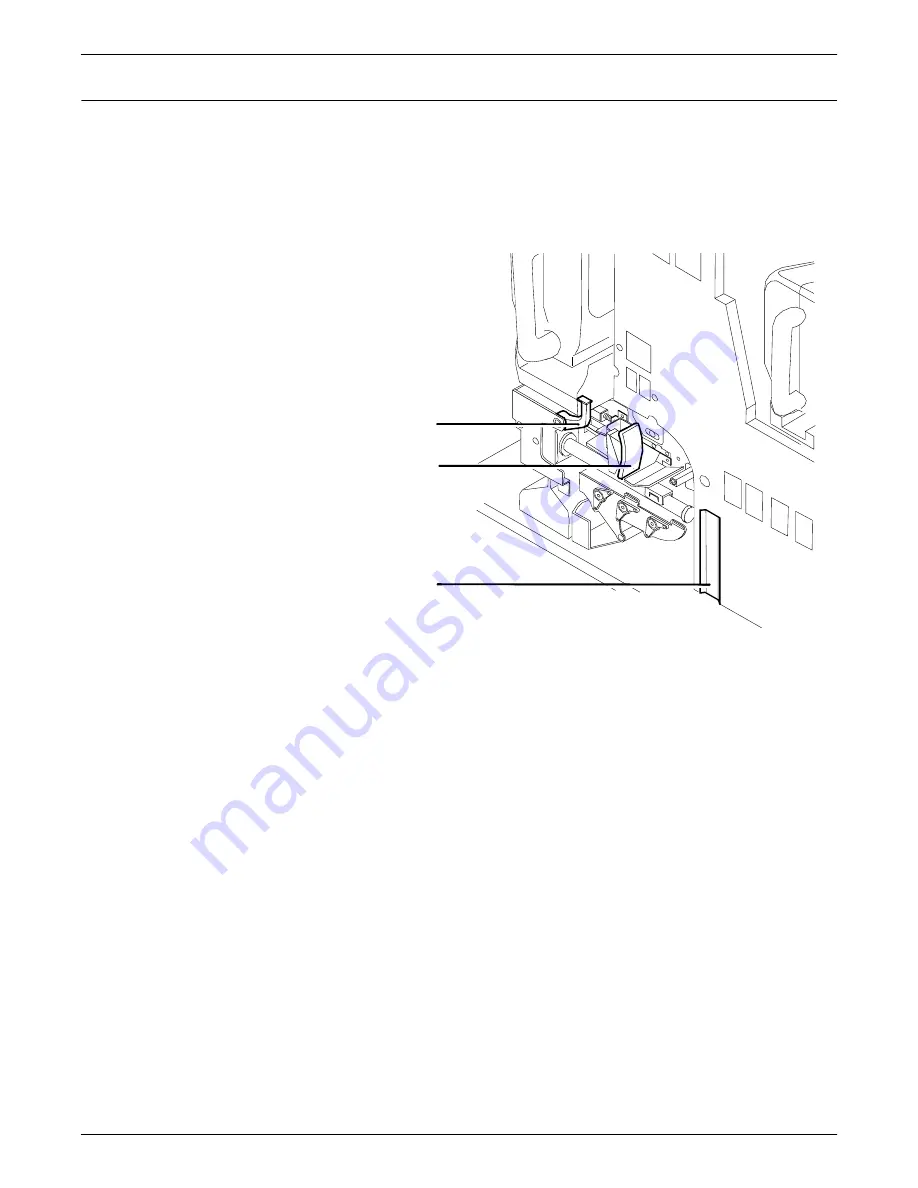

Removing the CCU

To remove the CCU from the printer, follow these steps.

1. When the printer is not cycled down, always press the Stop

button on the printer control console before you open the door

and attempt to remove the CCU.

2. Open the printer doors and locate the color housing area on the

left side of the printer.

1

Gold recess used to align cart

2

Gold backup roller handle

3 Gold

CCU

handle

1

2

3

Summary of Contents for DocuPrint 4850 IPS

Page 44: ...INKS 5 14 XEROX DOCUPRINT 4850 4890 IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE...

Page 52: ...WASTE CONTAINERS 6 8 XEROX DOCUPRINT 4850 4890 IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE...

Page 58: ...BYPASS TRANSPORT 7 6 XEROX DOCUPRINT 4850 4890 IPS GUIDE TO PERFORMING ROUTINE MAINTENANCE...