7

2.0 INSTALLATION

©2000 Xantrex Technology Inc.

Pre-Installation

(continued)

Tools required:

#2 Phillips screw driver

Level

Slotted screw driver

Wire strippers

Assorted open-end wrenches

Torque wrench

Socket wrench and fittings

Electrical tape

Multimeter (True rms)

Pencil

Hole saw

Utility knife

Hardware / Materials required:

4 ft. x 4 ft. sheet of 3/4" plywood or 2 x 4s studding material

#12 wood screws (or 1/2" x 1-1/4" lag bolts)

Conduit and appropriate fittings

Wire nuts

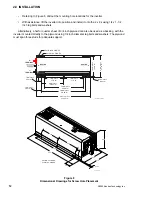

Wiring:

All wiring and installation methods should conform to applicable electrical and building codes.

Pre-plan the wire and conduit runs. The AC circuits accept cable sizes up to #6 AWG. The DC

circuits accept cable sizes up to #4/0 AWG.

For maximum safety, run both AC and DC cables in conduit.

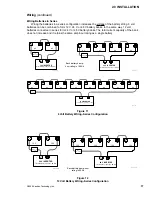

Refer to the Figure 25 (page 29) for an example of AC wiring to the sub-panel for 120 VAC

circuits.

AC Connections:

Use #6 AWG THHN wire for all AC wiring.

DC Connections:

Battery to inverter cabling should be only as long as required. If #4/0 AWG cables are used

for example, do not exceed 5 feet (one way) in 12 VDC systems; do not exceed 10 feet (one

way) in 24 VDC systems. For optimum performance, use pre-assembled battery cables

designed specifically for this application (available from Xantrex).

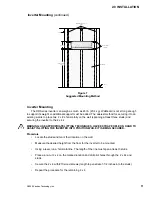

Grounding:

AC Grounding

The inverter/charger should be connected to a grounded, permanent wiring system. Neutral

and ground conductors should only be bonded at the main utility service panel.

DC Grounding

The negative battery conductor should be bonded to the grounding system at only one point

in the system. The size for the conductor is usually based on the size of the largest conductor

in the DC system.

Summary of Contents for Trace DR Series

Page 1: ...Installation Operator s Manual DR Series Inverter Charger ...

Page 2: ......

Page 81: ......

Page 82: ......

Page 83: ......