4

2

Calibration and Measurement

FREQUENCY OF CALIBRATION

Typically, the host computer prompts for an instrument calibration when required. The frequency at which this occurs

depends on the application. If desired, a reflection calibration can be invoked manually by pressing the Instrument

button—refer below for procedure. At a minimum the instrument should be calibrated once a day for best accuracy.

REFLECTION MODE CALIBRATION

The X-RiteColor AutoScan Spectrophotometer has a unique automatic calibration feature. When the instrument performs a

calibration procedure, the Color Reflection Reference is automatically scanned, simplifying the procedure. The instrument

employs a number of self-checking procedures to verify calibration accuracy during normal use. When internal limits are

exceeded, the computer calls for a calibration.

CALIBRATION NOTE:

Handle Color Reflection Reference by the edges. Make sure

that the Color Reflection Reference is free of dust, dirt, and

smudgemarks. Refer to Section Three for cleaning procedure.

Always store the Color Reflection Reference in its protective

envelope away from light and heat.

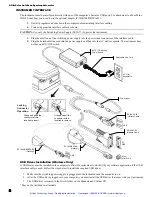

1.

Center the designated end of the Color Reflection

Reference under the alignment mark. Slowly insert strip

past the front idler rollers up to the black bar on the

reference strip.

2.

To manually force the instrument into calibration mode,

press and hold the Instrument button for a minimum of three

seconds.

The indicator light changes to yellow. Note, if calibration is

not performed after a short period of time, the instrument returns to

the measurement mode (green light).

3.

Press the Instrument button again. The light slowly flashes yellow.

After a few moments, the light changes to green and then back to

slow flashing yellow. The strip is then pulled through the instrument

and out the back. The light turns solid green after a successful

calibration. If the calibration fails (fast flashing yellow light), verify

strip is clean and re-read.

4.

Place Color Reflection Reference in its protective envelope.

NOTE:

The optics block must remain in the T/W position when

calibrating a DTP41/T instrument.

TRANSMISSION MODE (BLACK) CALIBRATION

NOTE: Transmission operation is optional. Therefore, transmission mode calibration may not be available on your

instrument.

A transmission calibration is recommended for the DTP41/T instrument approximately once a week for optimal

performance. The host computer initiates the procedure and prompts you to insert the calibration envelope (transmission

calibration cannot be initiated manually). This procedure guides you through the mechanical aspects of positioning the

envelope in the instrument.

1.

When the host computer indicates a transmission calibration is needed, center the designated end of the Color

Reflection Reference Envelope under the alignment mark. Slowly insert past the front idler rollers until it comes to

rest against the rear drive rollers (approx. three inches).

2.

Activate the cal procedure at the computer

. NOTE: This is a static measurement, the envelope is not pulled through

the instrument.

•

The instrument beeps once, flashes yellow slowly and takes a series of five measurements. After completion, the

instrument beeps again and the indicator light changes to solid green.

3.

Remove the Color Reflection Reference Envelope from the Instrument.

Press button

down for 3 sec. to

initiate calibration,

then press button

again

Slowly insert strip up

to the black bar

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Summary of Contents for AutoScan DTP41 Series

Page 3: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Page 7: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Page 16: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...