9

2.9.3

Remove the dipstick by rotating the cap

counterclockwise and pulling it out.

2.9.4

Wipe the dipstick with a clean cloth.

2.9.5

Fill the engine with oil.

2.9.6

Put the dipstick into the filler neck, then remove

it.

2.9.7

Read the oil level on the dipstick.

2.9.8

If the oil level is below the LOW or ADD mark

on the dipstick, add more oil to raise the oil level to

the FULL mark. If overfill, drain the excess oil until

the oil level on the dipstick reads FULL.

Important:

DO not overfill the crankcase with oil

and run the engine, engine damage will result.

2.9.9

Replace the dipstick into the filler neck and

rotate the cap clockwise until it is tight.

2.10 Check the Tire Pressure

Procedure

The tires are overinflated at the factory for shipping.

Reduce the pressure equally in both tires to between

12 and 15 psi (82 and 103 kPa).

2.11Check the Skids and Scraper

Procedure

Refer to Adjusting the Skids and Scraper in

Maintenance.

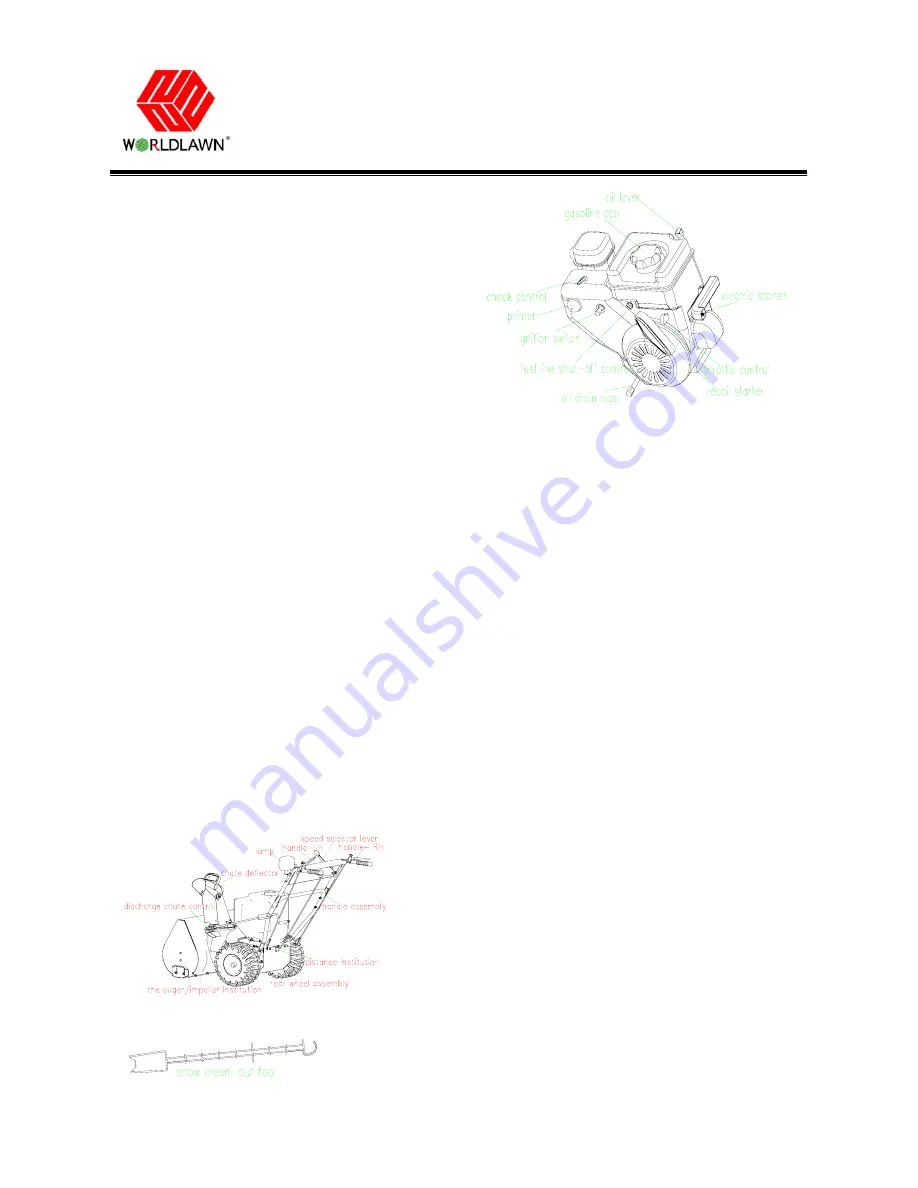

3. Product Overview

FIG

14

FIG

15

FIG 16

FIG 16 refer to engine instruction book

4

Controls

4.1 Auger/Impeller Drive Control Lever

To engage both the auger/impeller, press the lever

against the right handgrip. To disengage, release the

lever.

4.2 Traction Control Lever

To engage the traction, press the lever against the left

handgrip. To stop the traction, release the lever.

4.3 Speed Selector Lever

This control has 4 positions: 3 forward speeds and 1

reverse. To change speeds, move the speed selector

lever to the desired position. The lever locks in a

notch at each speed selection.

Note

:

Before shifting gears into or out of reverse,

you must release the traction control lever. You may

shift between any of the forward speeds without

releasing the traction control lever.

4.4 Handle-RH Locked Control

In operation process, the left side handle locks the

right side handle. Loosen the left one, the right side of

handle can be pressed or loosened freely; press the left

side handle, the right one can only be pressed, but not

be loosened.