Remove the cabinet front panel.

Check that the electrical supply and the gas service to the

appliance are off. See fig 3.

Check that all the water connections throughout the system are

tight.

Open the system valves at the appliance. See fig 3.

Open all the radiator valves, fill the system and vent each

radiator in turn.

The automatic air vent (fixed to the flow manifold) will vent the

appliance. Check that the air vent cap has been loosened.

see fig. 20.

Check that the pressure relief valve operates by turning the knob

ant-clockwise until it releases. Water should be expelled from the

discharge pipe. see fig. 28.

Lower the control box to gain access. Refer to Section 13.3(c).

Sealed systems only.

Set the Expansion Vessel Pressure.

The charge pressure of the expansion vessel as dispatched is

0.5 bar, which is equivalent to a static head of 5 meters (17ft).

The charge pressure must not be less than the static head at the

point of connection. See fig. 5. A Schraeder type valve is fitted to

the expansion vessel to allow the charge pressure to be

increased if necessary.

Set the System Pressure.

To fill the system, insert the bayonet end of the filling key into the

corresponding cut-outs in the filling loop housing and twist to

lock the key in place. See fig. 6.

Turn the system filling knob anti-clockwise to allow water ingress

and fill until the pressure gauge is at 2.5 bar (37 lb/in

2

).

Turn the knob cockwise to stop filling and remove the filling key

by lining up the bayonet end of the key with the cut-outs in the

filling loop housing and withdrawing the key. (See fig. 7.)

Check for water soundness.

Release water from the system using the relief valve test knob

(see fig. 28.), until the initial system design pressure is obtained,

up to a maximum of 1.5 bar.

Intial system design pressure (bar)=

Expansion vessel charge pr 0.3 (bar).

Note:

1 bar is equivalent to 10.2 meters (33.5 ft) of water.

N.B. The key must always be removed from the filling loop

housing after the system has been filled to comply with

Bylaw 14 of the Water Byelaws Scheme and to prevent

accidential filling.

Store the key in a safe place for future use.

Set the movable pointer on the pressure gauge to coincide with

the indicating pointer giving a permanent record of the set

system pressure.

If the pressure indicated on the pressure gauge is greater than

2.6 bar when operating at the maximum central heating

temperature, an extra expansion vessel must be fitted to the

system as close as possible to the appliance central heating

return connection.

The appliance (as despatched) can accommodate a system

volume of 83 litres. Refer to BS 7074 Part 1. If the system volume

is in excess of that accommodated by the expansion vessel fitted

to the appliance then an extra vessel must be fitted as close as

possible to the central heating return connection of the

appliance.

Any extra vessel fitted must be pressurised to the same figure as

the integral vessel. If the expansion vessel fails then the specified

replacement must be fitted.

20

11.1. Appliance and central heating

system preperation

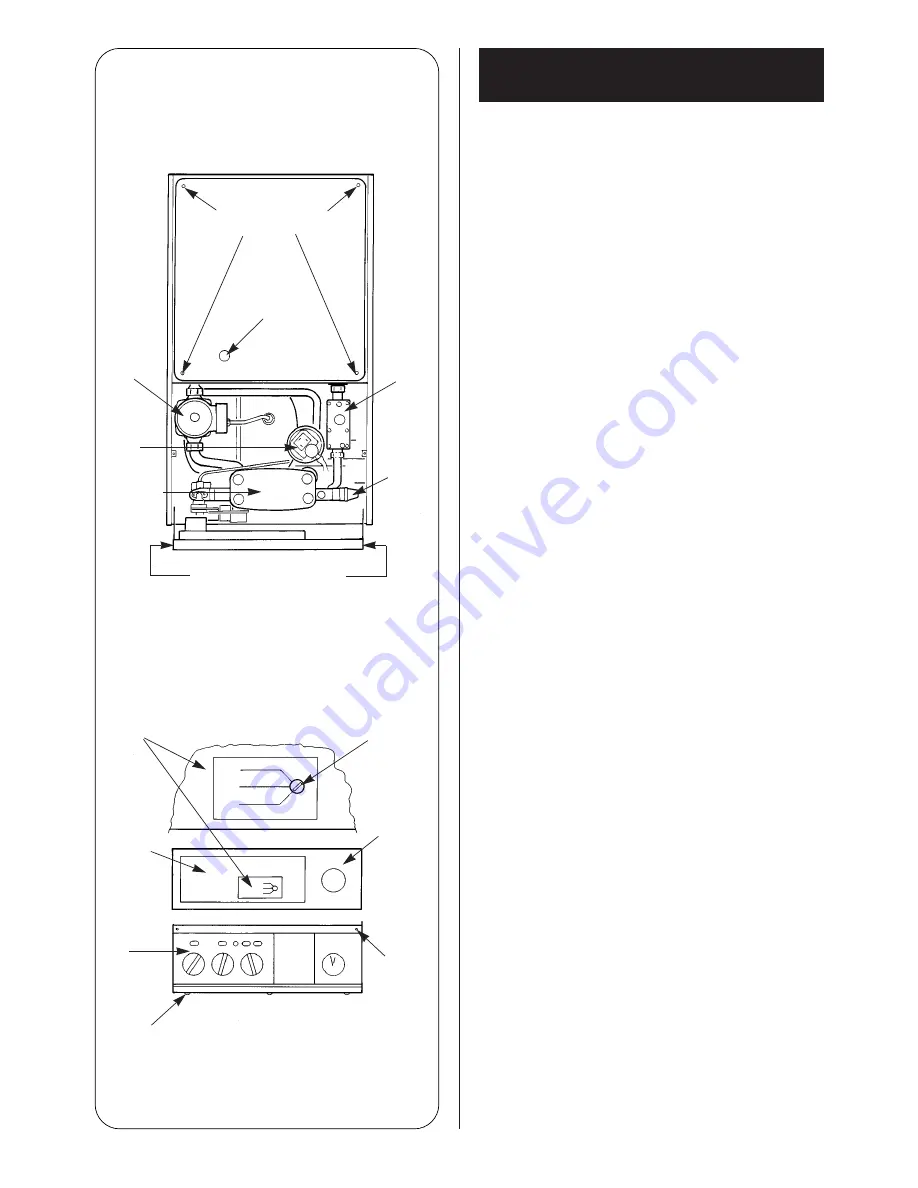

Fig. 27. Appliance Casing, Facia Controls and

Location of Equipment.

Inner casing cover

fixing screws (4)

Burner

observation

hole

Circulating

pump

Air

pressure

switch

Water to

water heat

exchanger

Gas

valve

Pressure

relief

valve

Facia shown in the service

position

Detail of gas valve

mode switch

MIN

MAX

NORMAL

Screwdriver slot

adjustment

Plastic

water cover

over controls

and gas

mode

switch

Rear of

facia

shown in

service

position

Facia

panel

fixing

screws

(2)

Front of

facia

panel

Bottom facia fixing

screws (3)

Summary of Contents for 26CDi Xtra

Page 35: ...35 96 NG OR LPG NG OR LPG 109 201 ...

Page 47: ...47 ...