24

Assembly

MAN1257 (3/23/2018)

DEALER CHECK LISTS

PRE-DELIVERY CHECK LIST

(DEALER’S RESPONSIBILITY)

Inspect the equipment thoroughly after assembly to ensure it is set up properly

before delivering it to the customer.

The following check lists are a reminder of points to inspect. Check off each

item as it is found satisfactory or after proper adjustment is made.

___

Check that all safety decals are installed and in good condition.

Replace if damaged.

___

Check that shields and guards are properly installed and in good con

-

dition. Replace if damaged.

___

Check all bolts to be sure they are properly torqued.

___

Check wheel bolts for proper torque.

___

Check that all cotter pins and safety pins are properly installed.

Replace if damaged.

___

Check that blades have been properly installed.

___

Check and grease all lubrication points as identified in lubrication infor

-

mation on page 13.

___

Check the level of gearbox fluids before delivery. Service, if required,

as specified in the lubrication information on page 13.

DELIVERY CHECK LIST

(DEALER’S RESPONSIBILITY)

___

Show customer how to make adjustments and select proper PTO

speed.

___

Show customer how to make sure driveline is properly installed and

that spring-activated locking pin or collar slides freely and is seated in

groove on tractor PTO shaft.

___

Show customer how to determine the turning limits of the CV PTO

driveline.

___

Show customer the safe, proper procedures to be used when mount

-

ing, dismounting, and storing equipment.

___

Make customer aware of optional equipment available so that cus

-

tomer can make proper choices as required.

___

Instruct customer how to lubricate and explain importance of lubrica

-

tion.

___

Point out the safety decals. Explain their meaning and the need to

keep them in place and in good condition. Emphasize the increased

safety hazards when instructions are not followed.

___

Explain to customer that when transporting the cutter, the wing and

center sections should be raised and their respective transport bars

installed and pinned in place.

___

Present Operator's Manual and request that customer and all opera

-

tors read it before operating equipment. Point out the manual safety

rules, explain their meanings and emphasize the increased safety haz

-

ards that exist when safety rules are not followed.

___

Explain to customer the potential crushing hazards of going under

-

neath raised equipment. Instruct that before going underneath to dis

-

connect the driveline, securely block up all corners with jack stands

and to follow all instructions in the BLOCKING METHOD, page 13 of

the operator’s manual. Explain that blocking up prevents equipment

dropping from hydraulic leak down, hydraulic system failures or

mechanical component failures.

___

Point out all guards and shields. Explain their importance and the

safety hazards that exist when not kept in place and in good condition.

___

Explain to customer that when towing on a public road to comply with

all state and local lighting/marking laws and to use a safety tow chain.

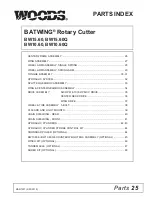

Summary of Contents for Batwing BW10.60E

Page 9: ...Declaration of Conformity9 MAN1257 3 23 2018...

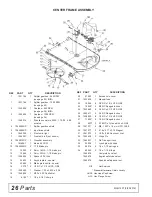

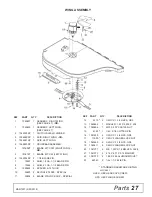

Page 30: ...30 Parts MAN1257 3 23 2018 TONGUE ASSEMBLY...

Page 54: ...BATWING FAUCHEUSE ROTATIVE MAN1257 R v 23 03 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 62: ...D claration de conformit 9 MAN1257 23 03 2018...

Page 76: ...BATWING TRINCIATRICE ROTANTE MAN1257 Rev 23 03 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 84: ...Dichiarazione di conformit 9 MAN1257 23 03 2018...

Page 98: ...BATWING ROLLSCHNEIDER MAN1257 Rev 23 03 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 106: ...Konformit tserkl rung 9 MAN1257 23 03 2018...

Page 120: ...BATWING DESBROZADORA GIRATORIA MAN1257 Rev 23 3 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 128: ...Declaraci n de conformidad 9 MAN1246 14 12 2017...