16

Owner Service

MAN1257 (3/23/2018)

Do not attempt to mount a tire unless you have the proper equipment and

experience to perform the job.

Always maintain the correct tire pressure. Do not inflate tires above the recom

-

mended pressure. Never weld or heat a wheel and tire assembly. The heat can

cause an increase in air pressure and result in a tire explosion. Welding can

structurally weaken or deform the wheel.

When inflating tires, use a clip-on chuck and an extension hose long enough to

allow you to stand to the side — not in front of or over the tire assembly. Use a

safety cage if available.

Check wheels for low pressure, cuts, bubbles, damaged rims, or missing lug

bolts and nuts.

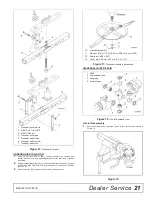

Never remove split rim assembly hardware (A) with the tire inflated.

Figure 8

. Split Rim Tire Servicing

CLEANING

After Each Use

●

Remove large debris such as clumps of dirt, grass, crop residue, etc.

from machine.

●

Inspect machine and replace worn or damaged parts.

●

Replace any safety decals that are missing or not readable.

Periodically or Before Extended Storage

●

Clean large debris such as clumps of dirt, grass, crop residue, etc. from

machine.

●

Remove the remainder using a low-pressure water spray.

1.

Be careful when spraying near scratched or torn safety decals or

near edges of decals as water spray can peel decal off surface.

2.

Be careful when spraying near chipped or scratched paint as water

spray can lift paint.

3.

If a pressure washer is used, follow the advice of the pressure

washer manufacturer.

●

Inspect machine and replace worn or damaged parts.

●

Sand down scratches and the edges of areas of missing paint and coat

with Woods spray paint of matching color (purchase from your Woods

dealer).

●

Replace any safety decals that are missing or not readable (supplied free

by your Woods dealer). See Safety Decals section for location drawing.

TROUBLESHOOTING

A

PN 1006348

PROBLEM

POSSIBLE CAUSE

SOLUTION

Does not cut

Dull blades

Sharpen blades.

Worn or broken blades

Replace blades. (Replace in pairs only.)

Incorrect PTO speed

Set at rated PTO speed.

Ground speed too fast

Reduce ground speed.

Drive not functioning (blades do not turn when

PTO is running)

Check drive shaft connection.

Check gearbox.

Gearbox malfunction

Repair gearbox.

Excessive clutch slippage

Adjust clutch.

Incorrect blade direction

Check to be sure blade edge is correct for direc

-

tion of rotation.

Streaks or ragged cut

Broken or worn blades

Replace or sharpen blades.

Attitude incorrect

Level machine.

Ground speed too fast

Reduce ground speed.

Excessive cutting height

Lower cutting height. (Note: Set height so blades

do not frequently hit ground.)

Excessive lush and tall vegetation

Recut at 90° to first pass.

Excessive side skid wear

Running with skids continuously on ground

Raise cutting height or adjust.

Excessive clutch slippage

Clutch out of adjustment

Adjust clutch.

Clutch discs worn; wear stops

contacting opposite plate

Replace discs.

Blades hitting ground

Raise cutting height.

Vibration

Broken blade

Replace blades in pairs.

Bearing failure

Check gearbox shafts for side play.

Hitch length incorrect

Reset hitch length.

Universal drive

Adjust pedestal bearing height to be parallel to

ground.

Blades hitting deck

Bent blades or crossbar

Replace bent blades or crossbar.

Unit will not raise

Low oil

Add hydraulic oil.

Unit doesn’t cut level

Wing section cuts lower than

center

Lengthen turnbuckle connecting center yoke to

wing wheel yoke.

Wing section cuts higher than

center

Shorten turnbuckle connecting center yoke to

wing wheel yoke.

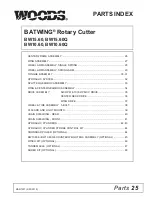

Summary of Contents for Batwing BW10.60E

Page 9: ...Declaration of Conformity9 MAN1257 3 23 2018...

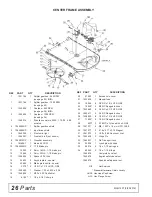

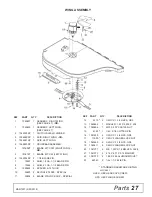

Page 30: ...30 Parts MAN1257 3 23 2018 TONGUE ASSEMBLY...

Page 54: ...BATWING FAUCHEUSE ROTATIVE MAN1257 R v 23 03 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 62: ...D claration de conformit 9 MAN1257 23 03 2018...

Page 76: ...BATWING TRINCIATRICE ROTANTE MAN1257 Rev 23 03 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 84: ...Dichiarazione di conformit 9 MAN1257 23 03 2018...

Page 98: ...BATWING ROLLSCHNEIDER MAN1257 Rev 23 03 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 106: ...Konformit tserkl rung 9 MAN1257 23 03 2018...

Page 120: ...BATWING DESBROZADORA GIRATORIA MAN1257 Rev 23 3 2018 BW15 60E BW15 60QE BW10 60E BW10 60QE...

Page 128: ...Declaraci n de conformidad 9 MAN1246 14 12 2017...