47

3062547_201802

29 Cascade operation - Flue gas

damper tightness test

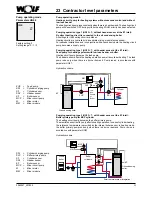

Tightness test on

connections to adjacent

appliances

As part of the annual heating appliance inspection, the cascade

damper on overpressure boiler systems must be tested for tightness,

to ensure no flue gas can escape into the boiler room. Flue gas can

lead to asphyxiation or severe to life-threatening poisoning.

The check must be carried out with the appliance closed.

Tightness test on connections to adjacent appliances

- Set the program selector (l.h. rotary selector) to "Standby" on the BM

programming unit.

- Then turn the first COB to position 1 "Emissions test" by means of the heating

water temperature selector

è

COB starts.

- Operate the first COB for at least 5 minutes.

- Check the CO

2

content in the air connectors on all other appliances:

- If the CO

2

value exceeds 0.2% within 15 minutes, the leak must be found and

remedied.

- Subsequently close all test apertures again. When doing so, ensure the caps are

seated firmly.

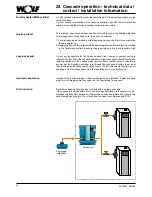

Testing the first COB for tightness

- Turn the temperature selector for heating water on the first COB to its centre

position

è

COB shuts down.

- The turn the second COB to position 1 "Emissions test" by means of the heating

water temperature selector

è

COB starts.

- Operate the second COB for at least 5 minutes.

- Carry out the CO

2

test on the first COB.

- If the CO

2

value exceeds 0.2% within 15 minutes, the leak must be found and

remedied.

- Subsequently close all test apertures again. When doing so, ensure the caps are

seated firmly.

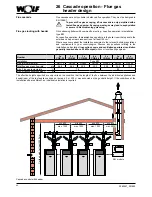

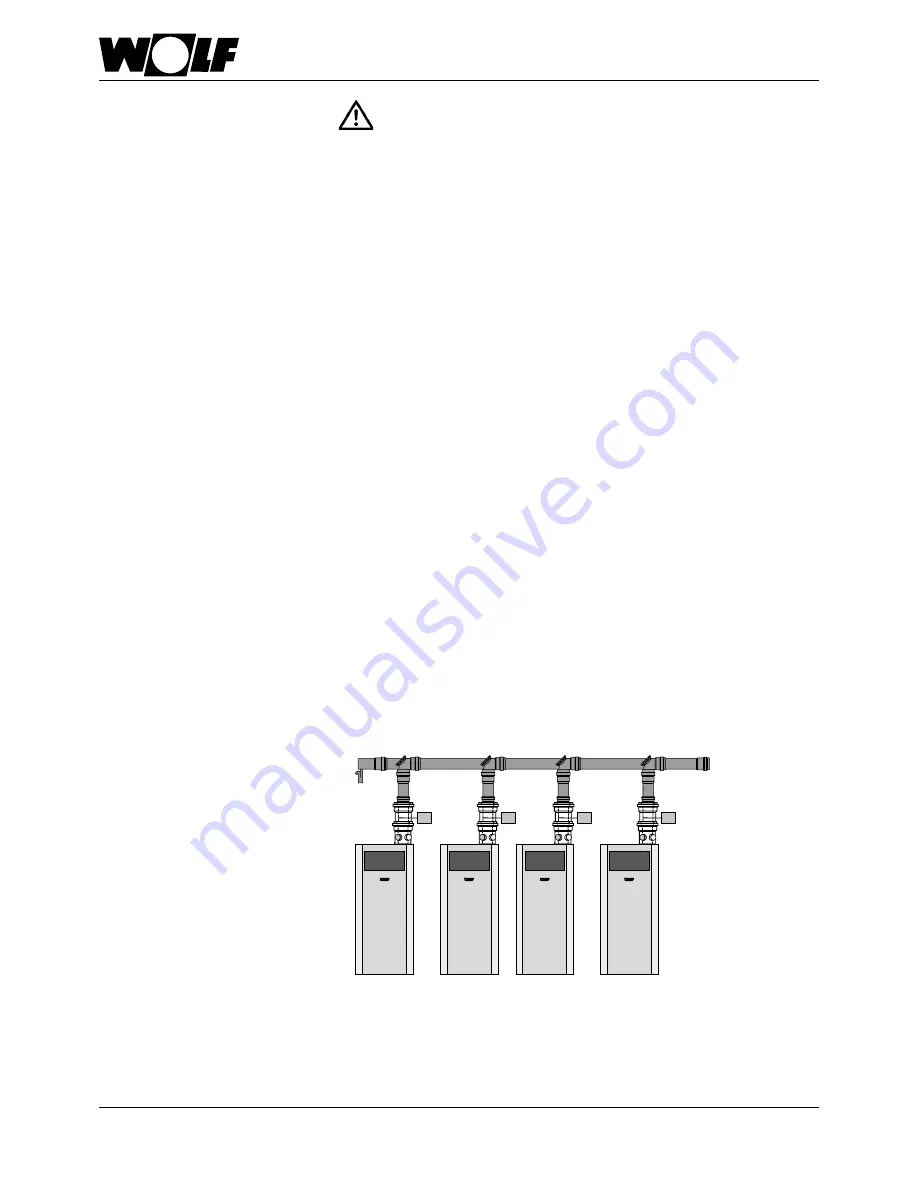

1

2

3

4

1. ON

OFF

OFF

OFF

2. OFF

ON

OFF

OFF

Summary of Contents for COB

Page 78: ...78 3062547_201802 43 Notes ...

Page 79: ...79 3062547_201802 43 Notes ...